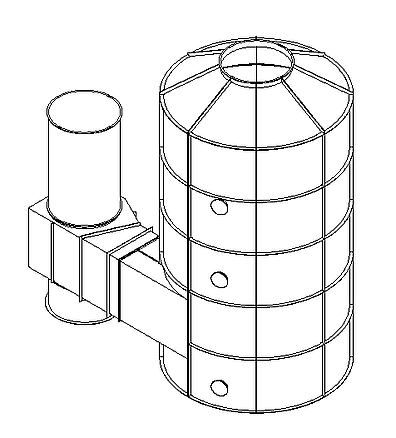

The US Department of Energy (DOE) has funded R&D in coal gasification in recent years as part of a strategy to reduce green house gases. One aspect of this technology is the use of coal dryers to dry the coal before feeding it into the gasifier. This requires a coal dryer scrubber which can be comprised of a Venturi scrubber followed by a condenser tower shown in the sketch.

house gases. One aspect of this technology is the use of coal dryers to dry the coal before feeding it into the gasifier. This requires a coal dryer scrubber which can be comprised of a Venturi scrubber followed by a condenser tower shown in the sketch.

The exhaust gas from the dryer passes through a Venturi scrubber for particulate removal then through a condenser tower to condense water vapor in the gas stream. The gas passes through a mist eliminator at the top of the condenser tower to remove water droplets in the gas stream. Re-circulated water in the Venturi throat is collected in the sump of the condenser tower. Gas flow rates for these processes are relatively large and can exceed 300,000 acfm. Because of the large gas flows, the condenser tower can be as large as 20 feet in diameter or larger. The Venturi scrubber (shown in the image on the left) must have a special throat design to account for the large gas flow rate. The Venturi throat design is discussed in in the previous blog post for Venturi Scrubber Throat Design for Large Gas Flow Processes.

tower. Gas flow rates for these processes are relatively large and can exceed 300,000 acfm. Because of the large gas flows, the condenser tower can be as large as 20 feet in diameter or larger. The Venturi scrubber (shown in the image on the left) must have a special throat design to account for the large gas flow rate. The Venturi throat design is discussed in in the previous blog post for Venturi Scrubber Throat Design for Large Gas Flow Processes.

To learn more about this application, please download our case study.