As an equipment supplier of custom engineered wet scrubber equipment, Envitech frequently provides lunch and learns (L&L’s) to engineering companies to help educate engineers about the basics of available technology.

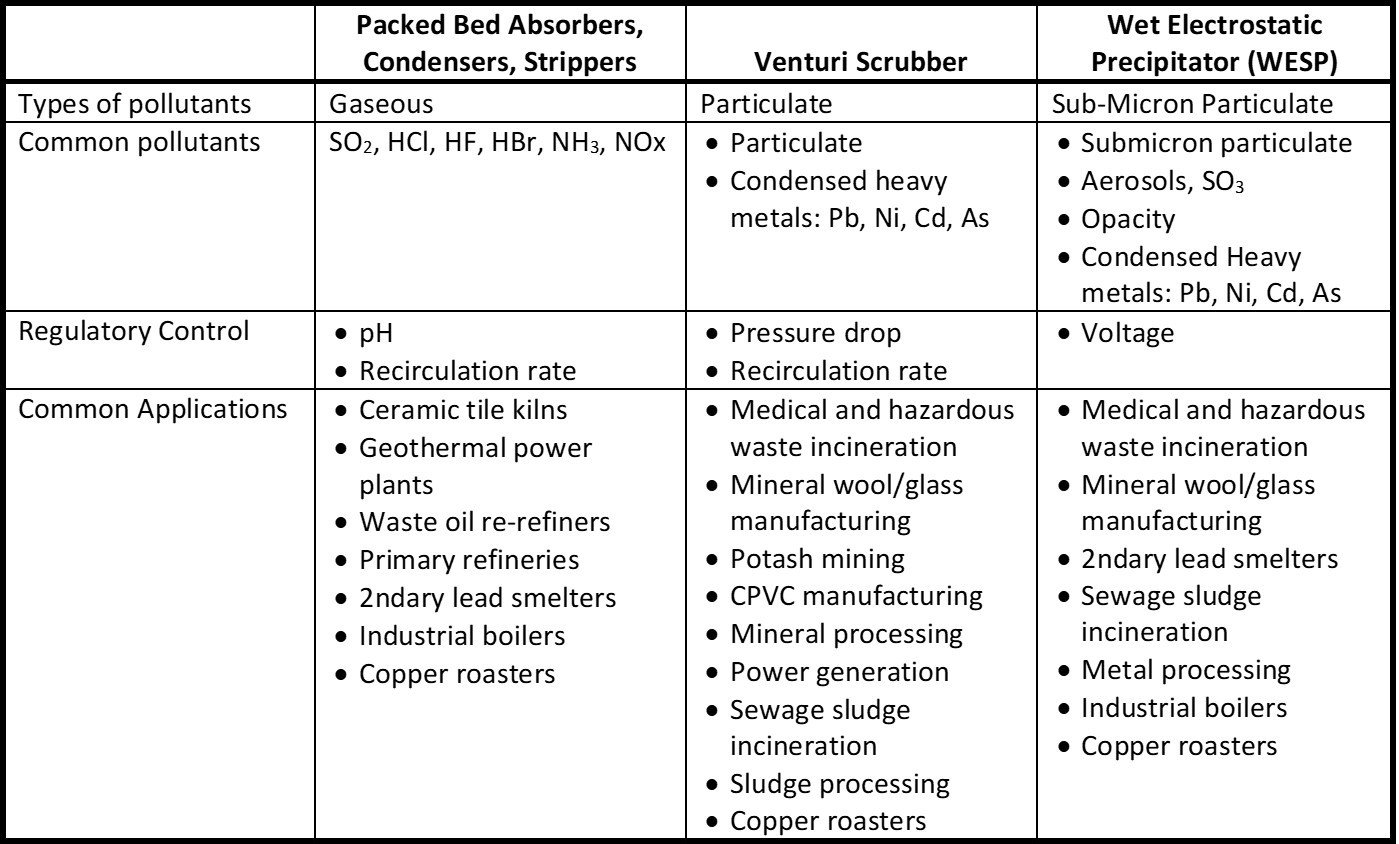

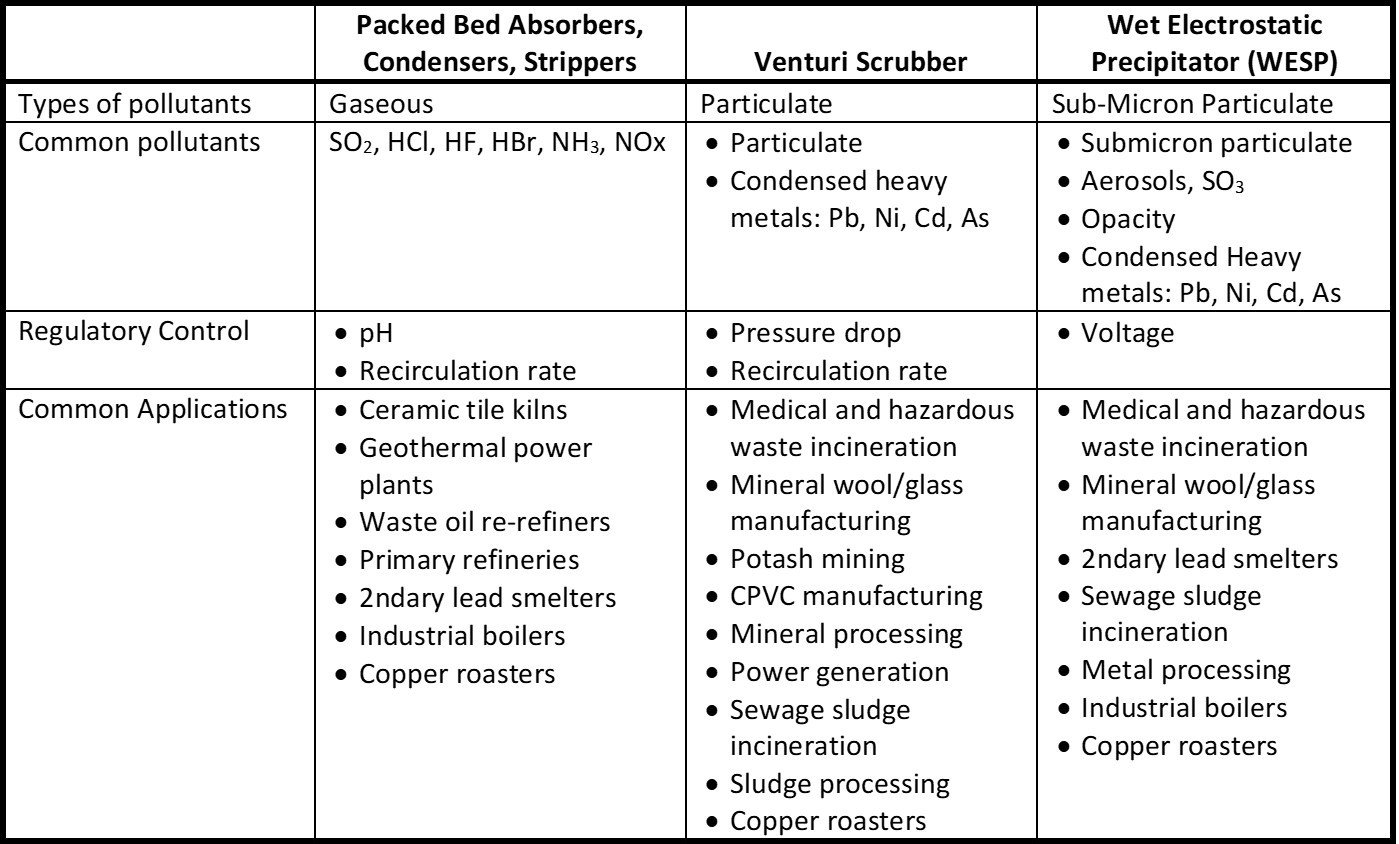

Figure 1 below is a summary chart of predominant wet scrubber technology options. The main product categories include packed bed absorbers, Venturi scrubbers, and wet electrostatic precipitators (WESPs). Each wet scrubber type serves a different purpose and is used in different circumstances. For instance, packed bed absorbers are primarily used to remove gaseous emissions like SO2, HCl, or HF. We often receive packed bed absorber inquiries for particulate removal, however, this would be a misuse of technology. Packed bed absorbers remove some particulate but they are not nearly as efficient as other options.

Figure 1: Wet scrubber technology summary

Venturi scrubbers are used for particulate removal. Just like we sometimes receive packed bed absorber inquiries for particulate removal, we’ll occasionally get Venturi scrubber inquiries for acid gas removal. This would also be a misuse of technology. Venturi scrubbers achieve some acid gas removal, but they have poor mass transfer compared to a packed bed absorbers.

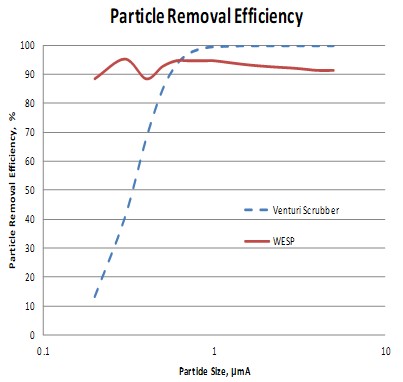

Venturi scrubbers use mechanical forces to remove particulate. Particles are captured through a process of impaction between particles in the gas and water droplets in the Venturi throat. A high differential velocity is created between particles and droplets by accelerating the gas in the throat. A pressure drop in the throat provides energy to capture the particles. Smaller particles less than 1 micron in size avoid capture by behaving like gas molecules and finding slip streams around the water droplets. Venturi scrubber performance drops offs exponentially for submicron particulate. Overall removal efficiency may be limited for a gas stream with a high concentration of submicron particulate. Venturi scrubbers are a good choice for industrial dryers or other applications with large size particulate.

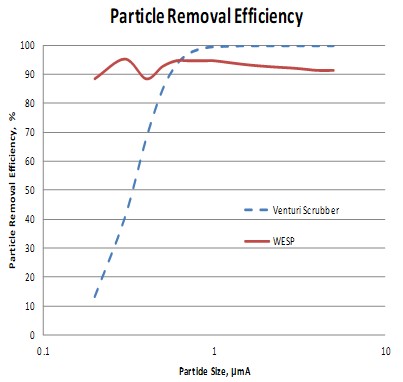

Wet electrostatic precipitator (WESP) are the third type of wet scrubber summarized in the table. Like Venturi scrubbers, they are also particulate removal devices. They differ from Venturi scrubbers in a couple of ways, 1.) electrical, not mechanical forces are used to capture particulate, and 2,) they are efficient at capturing submicron particulate. Figure 2 shows a performance comparison between a WESP and Venturi scrubber. It can be seen that performance drops off dramatically for Venturi scrubbers for particles less than 1 micron in size. WESP’s on the other hand remove particles regardless of particle size.

Figure 2: WESP, Venturi scrubber performance comparison versus particle size.

The summary in Figure 1 also shows how each wet scrubber technology differs in regulatory control. A packed bed absorber is typically controlled for recirculation flow rate and liquid pH. A Venturi scrubber is controlled by recirculation rate and pressure drop. A WESP is controlled by voltage. Control limits are typically spelled out in the operating permit.

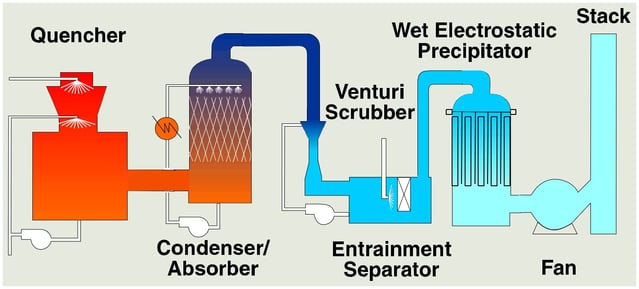

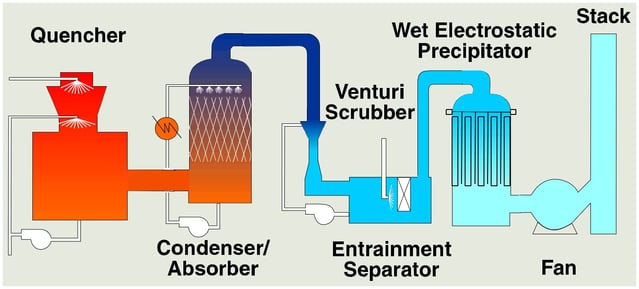

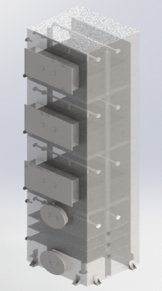

Finally, some examples of applications are given for each type of wet scrubber. It should be noted that there are many applications that have multiple types of pollutants. A hazardous waste incinerator, for instance, contains particulate, acid gases, and specific heavy metals like cadmium and lead. A fraction of particulate is submicron in size and difficult for a Venturi scrubber to remove. It is common for different types of wet scrubbers to be combined into a multi-pollutant device. Figure 3 shows a common arrangement for an incinerator scrubber. The gas is first cooled in a quencher. A packed bed absorber removes acid gases. A Venturi scrubber removes particulate and a WESP removes the submicron particulate and heavy metals.

Figure 3: Incinerator wet scrubber arrangement

Wet scrubbers can also be combined with dry scrubbers in certain circumstances. An upstream bag-house can remove particulate followed by a packed bed absorber for acid gas removal. A cyclone can be used to knock out large particulate before using a Venturi scrubber for the remaining particulate. A cyclone helps to minimize blowdown and water consumption. In some cases, a dry filter or carbon bed absorber can be integrated downstream of a wet scrubber for mercury and/or dioxin/furan. Click here to read a blog piece about an example of a wet scrubber combined with a carbon bed.

This about covers wet scrubber basics. If you’re with an engineering company and want to discuss scheduling a lunch an learn, please give Envitech a call. You can click on the icon below for a set of Envitech brochures.

Click on the icon below to download an Envitech brochure.

food waste per day into 100 MMBtu/d of renewable energy biogas. The digester is sited near campus at a decommissioned landfill.

food waste per day into 100 MMBtu/d of renewable energy biogas. The digester is sited near campus at a decommissioned landfill.  ith HMI, pre-assembled pump, piping, valves and fittings, ID fan with VFD, and free-standing interconnect duct and stack.

ith HMI, pre-assembled pump, piping, valves and fittings, ID fan with VFD, and free-standing interconnect duct and stack.

into a consistent granular media. The media is used as a natural microbial carrier to inoculate millions of acres of food crops each year. The transformation process relies on drying harvested material in industrial rotary dryers. A fraction of the material becomes entrained in the flue gas as particulate emissions. The facility is expanding operations to double the capacity. A scrubber solution is needed to reduce total plant particulate emissions.

into a consistent granular media. The media is used as a natural microbial carrier to inoculate millions of acres of food crops each year. The transformation process relies on drying harvested material in industrial rotary dryers. A fraction of the material becomes entrained in the flue gas as particulate emissions. The facility is expanding operations to double the capacity. A scrubber solution is needed to reduce total plant particulate emissions. ers. The scrubbers are comprised of a variable throat Venturi scrubber and a chevron style entrainment separator mounted on an equipment skid. The scope of supply for each scrubber includes a control system, re-circulation pump with pre-assembled piping, valves and fittings. Instruments are pre-mounted in the piping where possible and pre-wired to a junction box on the skid. The horizontal configuration provides a compact design to fit inside the building with easy maintenance access to valves and instruments.

ers. The scrubbers are comprised of a variable throat Venturi scrubber and a chevron style entrainment separator mounted on an equipment skid. The scope of supply for each scrubber includes a control system, re-circulation pump with pre-assembled piping, valves and fittings. Instruments are pre-mounted in the piping where possible and pre-wired to a junction box on the skid. The horizontal configuration provides a compact design to fit inside the building with easy maintenance access to valves and instruments.

. Batches occur over a 20-hour period and ammonia concentrations varies from <1 to 96%.

. Batches occur over a 20-hour period and ammonia concentrations varies from <1 to 96%.

reduce organic compounds using a catalyst. In-situ regeneration is desired to restore the catalyst for additional processing. This improves operational efficiency and safety. The facility is evaluating technology options to achieve this goal. One approach is to

reduce organic compounds using a catalyst. In-situ regeneration is desired to restore the catalyst for additional processing. This improves operational efficiency and safety. The facility is evaluating technology options to achieve this goal. One approach is to  is T316SS conforming to ASME B31.1. Welds are specified to be magnetically and X-ray tested using certified welders.

is T316SS conforming to ASME B31.1. Welds are specified to be magnetically and X-ray tested using certified welders.

needed to remove particulate from a chlorine gas stream that originates in the anode compartments of electrolytic cells that produce magnesium metal. A significant portion of the particulate is less than 1 micron in size, making it difficult to remove.

needed to remove particulate from a chlorine gas stream that originates in the anode compartments of electrolytic cells that produce magnesium metal. A significant portion of the particulate is less than 1 micron in size, making it difficult to remove. tic (FRP) Venturi scrubber and horizontal chevron style entrainment separator. Additional scope of supply includes instruments, pre-assembled pump skid with redundant titanium pumps (1 operating and 1 spare), pre-assembled CPVC piping, redundant fans with titanium wheel and housing, interconnect FRP ductwork, dampers, and equipment skid and platforms.

tic (FRP) Venturi scrubber and horizontal chevron style entrainment separator. Additional scope of supply includes instruments, pre-assembled pump skid with redundant titanium pumps (1 operating and 1 spare), pre-assembled CPVC piping, redundant fans with titanium wheel and housing, interconnect FRP ductwork, dampers, and equipment skid and platforms.

The thermal oxidizers need a wet scrubber to neutralize and remove SO2. Flue gas entering the scrubber contain some sulfur trioxide (SO3) which is converted to sulfuric acid (H2SO4) in the quencher. Sulfuric acid is a submicron liquid aerosol that passes through the downstream packed bed absorber. Some facilities are now being regulated for H2SO4. This paper evaluates and compares candle filters versus wet electrostatic precipitators (WESP’s) for H2SO4 removal in these applications.

The thermal oxidizers need a wet scrubber to neutralize and remove SO2. Flue gas entering the scrubber contain some sulfur trioxide (SO3) which is converted to sulfuric acid (H2SO4) in the quencher. Sulfuric acid is a submicron liquid aerosol that passes through the downstream packed bed absorber. Some facilities are now being regulated for H2SO4. This paper evaluates and compares candle filters versus wet electrostatic precipitators (WESP’s) for H2SO4 removal in these applications. Waste water treatment facilities operating sewage sludge incinerators (SSI) can reduce sludge volume and disposal costs by combusting dewatered sewage sludge. Emissions are regulated by the US EPA Maximum Available Control Technology (MACT) standard 40 CFR Part 60 and 62 to control particulate, lead (Pb), cadmium (Cd), SO2, HCl, dioxins/furans, and mercury (Hg). Many SSI’s need a control device specifically for mercury. This paper evaluates two mercury control technologies: sulfur‐impregnated activated carbon and Gore sorbent polymer catalyst (SPC) modules. Several facilities have used sulfur-impregnated activated carbon but safety issues have arisen due to fires which have shut down some systems. The Gore SPC modules are a relatively new technology with at least seven installations. A comparison is made of capital cost, operating cost, mercury removal efficiency, fire and performance risks based on incineration of 3,000 lbs/hr of sewage sludge. Finally, an overview is provided for an Envitech SPC mercury control scrubber operating at one facility.

Waste water treatment facilities operating sewage sludge incinerators (SSI) can reduce sludge volume and disposal costs by combusting dewatered sewage sludge. Emissions are regulated by the US EPA Maximum Available Control Technology (MACT) standard 40 CFR Part 60 and 62 to control particulate, lead (Pb), cadmium (Cd), SO2, HCl, dioxins/furans, and mercury (Hg). Many SSI’s need a control device specifically for mercury. This paper evaluates two mercury control technologies: sulfur‐impregnated activated carbon and Gore sorbent polymer catalyst (SPC) modules. Several facilities have used sulfur-impregnated activated carbon but safety issues have arisen due to fires which have shut down some systems. The Gore SPC modules are a relatively new technology with at least seven installations. A comparison is made of capital cost, operating cost, mercury removal efficiency, fire and performance risks based on incineration of 3,000 lbs/hr of sewage sludge. Finally, an overview is provided for an Envitech SPC mercury control scrubber operating at one facility.

Hazardous Waste Combustors (

Hazardous Waste Combustors (

incinerator had been shut down due to safety issues with the granulated activated carbon (GAC) mercury control scrubber. The plant sought expert help to evaluate and recommend a technology solution to replace the GAC and to get the SSI back in operation.

incinerator had been shut down due to safety issues with the granulated activated carbon (GAC) mercury control scrubber. The plant sought expert help to evaluate and recommend a technology solution to replace the GAC and to get the SSI back in operation. available literature and data to establish a conservative but justifiable design inlet concentration with sufficient capacity to meet a more conservative design condition without structural changes to the equipment.

available literature and data to establish a conservative but justifiable design inlet concentration with sufficient capacity to meet a more conservative design condition without structural changes to the equipment.