Packed bed absorbers are often used to treat gaseous emissions for reasonably large gas flow rates ranging from a few thousand cfm to greater than 70,000 cfm. Common emissions include SOx, HCl, HF, and NOx. The absorbers are often custom engineered for a specific plants and have been used for secondary lead smelters, geothermal power plants, waste oil-re-refiners, ceramic tile manufacturing, waste incinerators, and ethanol plants. The types of emission sources range from thermal oxidizers, regenerative thermal oxidizers (RTO’s), furnaces, kilns, direct fired heaters, incinerators, fermenters, vent tanks, and batch mixers.

Envitech developed a lab scrubber to provide an economic solution for smaller gas flow rate applications. The lab scrubber is a packaged unit designed for high efficiency of water soluble contaminants and can handle up to 2,000 cfm of gas at a maximum temperature of 180°F. The system is engineered for reduced footprint at 4 ft x 4 ft and includes a pre-wired control panel and pre-piped service utility connections requiring minimal installation and maintenance costs. Scrubber units are configurable to different levels of automation and treatment applications.

Envitech developed a lab scrubber to provide an economic solution for smaller gas flow rate applications. The lab scrubber is a packaged unit designed for high efficiency of water soluble contaminants and can handle up to 2,000 cfm of gas at a maximum temperature of 180°F. The system is engineered for reduced footprint at 4 ft x 4 ft and includes a pre-wired control panel and pre-piped service utility connections requiring minimal installation and maintenance costs. Scrubber units are configurable to different levels of automation and treatment applications.

A recent lab scrubber is for a manufacturer of pharmaceutical products in Southern, California. The scrubber is designed to remove HCl from the exhaust of several small laboratory process vent streams. The vent streams includes low organic concentrations which are incompatible with many common plastic materials. Special resin was selected for the fiber reinforced plastic (FRP) vessel and ductwork. Piping and valves were assembled using PVDF. The scrubber is designed for a classified area with explosion proof motors and instruments and is provided as a turn-key installation.

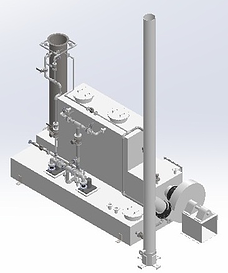

Another example is a process vent scrubber for a blending facility in South Carolina that produces crop protection products for agricultural markets. The vent stream is 1,500 cfm and includes HCl and water soluble particulate greater than 3 micron in size. The Envitech lab scrubber was configured to include a low pressure drop Venturi for particulate control combined with a packed bed absorber for HCl control. The system includes instruments, control system, recirculation pump, pre-assembled piping, valves, and fittings, interconnect duct, ID fan, and stack.

Another example is a process vent scrubber for a blending facility in South Carolina that produces crop protection products for agricultural markets. The vent stream is 1,500 cfm and includes HCl and water soluble particulate greater than 3 micron in size. The Envitech lab scrubber was configured to include a low pressure drop Venturi for particulate control combined with a packed bed absorber for HCl control. The system includes instruments, control system, recirculation pump, pre-assembled piping, valves, and fittings, interconnect duct, ID fan, and stack.

A different use for a lab scrubber includes an ethylenediamine (EDA) scrubber installed in the South Eastern United States. The storage of this precursor chemical requires extra handling than is typical with other common industrial chemicals. With a relatively low exposure limit of 10 ppm, storage tanks must be properly engineered and scrubbed to remove excess vapors. The Envitech lab scrubber is an ideal, low cost solution for this type of storage system.

A different use for a lab scrubber includes an ethylenediamine (EDA) scrubber installed in the South Eastern United States. The storage of this precursor chemical requires extra handling than is typical with other common industrial chemicals. With a relatively low exposure limit of 10 ppm, storage tanks must be properly engineered and scrubbed to remove excess vapors. The Envitech lab scrubber is an ideal, low cost solution for this type of storage system.

Please click on the link below to download a brochure and case studies for the lab scrubber.

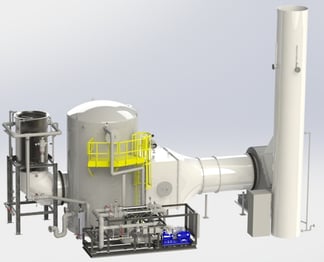

incinerator. The incinerator exhaust is ducted to a metal quencher (shown in the foreground). The hot gas enters the top of the quencher and flows vertically downward. The gas then elbows into the bottom of a vertical packed bed scrubber (shown in the background). The gas passes upward through the packed bed as re-circulated water flows downward, counter-current to the gas from the top of the packed bed. Water from the quencher and packed bed is collected in the sump and re-circulated back to the quencher and packed bed. An entrainment separator at the top of the scrubber removes entrained water droplets. After exiting the scrubber vessel, an interconnect duct transports the gas to a induced draft fan located at grade.

incinerator. The incinerator exhaust is ducted to a metal quencher (shown in the foreground). The hot gas enters the top of the quencher and flows vertically downward. The gas then elbows into the bottom of a vertical packed bed scrubber (shown in the background). The gas passes upward through the packed bed as re-circulated water flows downward, counter-current to the gas from the top of the packed bed. Water from the quencher and packed bed is collected in the sump and re-circulated back to the quencher and packed bed. An entrainment separator at the top of the scrubber removes entrained water droplets. After exiting the scrubber vessel, an interconnect duct transports the gas to a induced draft fan located at grade.

cinerator and waste heat boiler treats the TGTU off-gas before it is exhausted to atmosphere. During normal operations, there is very little SO2 emissions due to the high sulfur recovery. However, TGTU upsets can occur several times per year which sends unrecovered sulfur to the incinerator. During these upsets, SO2 emissions can be as high as 1 tph or more for a period of 8 to 12 hours.

cinerator and waste heat boiler treats the TGTU off-gas before it is exhausted to atmosphere. During normal operations, there is very little SO2 emissions due to the high sulfur recovery. However, TGTU upsets can occur several times per year which sends unrecovered sulfur to the incinerator. During these upsets, SO2 emissions can be as high as 1 tph or more for a period of 8 to 12 hours.

In 2012 Envitech designed and built a

In 2012 Envitech designed and built a

from the earth’s geothermal resources into electrical energy. The fluids are recovered in the

from the earth’s geothermal resources into electrical energy. The fluids are recovered in the

from used automobile batteries. The process uses a combination of combustion processes including kilns and furnaces. Despite extensive control equipment including bag-houses, HEPA filters, and wet scrubbers, low concentrations of heavy metals were being emitted from various stack sources. Cancer risk index standards were being exceeded due to the close proximity of residents to the plant. To be compliant with state regulations a solution was needed to reduce these emissions. The special circumstances of nearby residents and a stringent cancer risk index required the facility to meet emission limits well below any other secondary lead smelter in the country.

from used automobile batteries. The process uses a combination of combustion processes including kilns and furnaces. Despite extensive control equipment including bag-houses, HEPA filters, and wet scrubbers, low concentrations of heavy metals were being emitted from various stack sources. Cancer risk index standards were being exceeded due to the close proximity of residents to the plant. To be compliant with state regulations a solution was needed to reduce these emissions. The special circumstances of nearby residents and a stringent cancer risk index required the facility to meet emission limits well below any other secondary lead smelter in the country.

will increase production to nearly 20 MM gpy. The state requires a direct fired heater to reduce SO2 emissions by 95%. Although packed bed scrubbers are common for this type of process, a vertical scrubber design can be expensive to retrofit into an existing facility. The facility was looking for a solution to meet or exceed emission standards and be relatively simple to install and maintain.

will increase production to nearly 20 MM gpy. The state requires a direct fired heater to reduce SO2 emissions by 95%. Although packed bed scrubbers are common for this type of process, a vertical scrubber design can be expensive to retrofit into an existing facility. The facility was looking for a solution to meet or exceed emission standards and be relatively simple to install and maintain.