Envitech's Dual Alkali Scrubber Reduces SO2 Greater than 90%

Ozone, Haze, & New Source Review (NSR) rules require regional improvement in air quality. Many states are requiring greater than 90% SO2 removal for industrial sources. However, many plants have limited or no industrial waste water discharge capacity for conventional, high efficiency wet scrubbers. The Envitech dual alkali scrubber offers high removal efficiency with no liquid discharge and low operating cost.

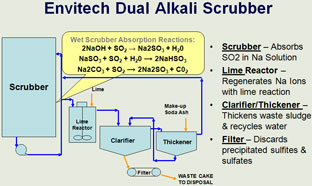

Widely used in flue gas desulfurization (FGD) systems dating from the early 1980's, a dual alkali scrubber uses an indirect lime process for removing acid gas with a sodium-based absorbent. The sodium absorbent is regenerated through reaction with lime in a secondary water recycle unit. Calcium sulfite/sulfate is precipitated and discarded. Water and sodium ions are recycled back to the dual alkali scrubber. The system has zero liquid discharge and eliminates the need for a waste water discharge permit. Using lime to capture the SO2 reduces operating costs as compared to using either caustic or soda ash.

Envitech Technologies:

Acid Gas Scrubber | Ammonia Scrubber | Chlorine Scrubber | Fiberglass Scrubber | HBr Scrubber | HCl Scrubber | HF Scrubber | Packed Bed Scrubber | Packed Tower | RTO Scrubber | SO2 Removal | Sulfur Dioxide Scrubber | Thermal Oxidizer Scrubber