Ceramic Tile Kilns

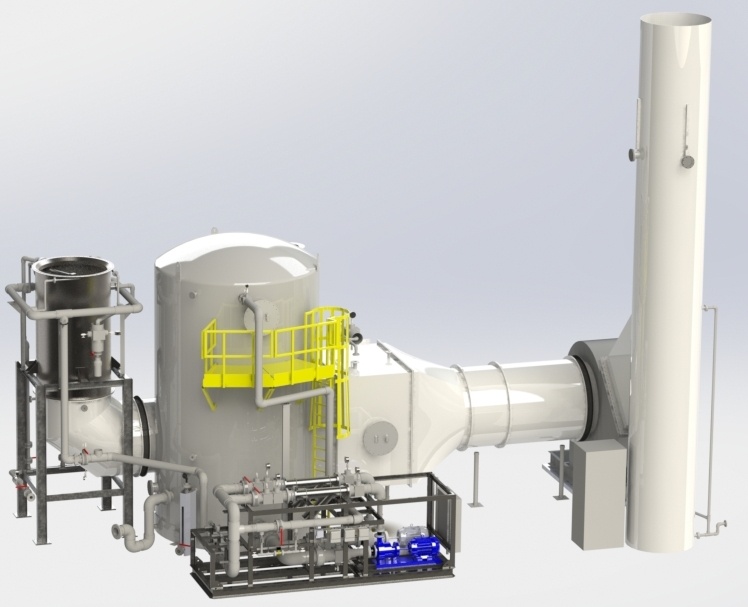

Ceramic tile manufacturing involves the mining of raw materials which include a mixture of clay and minerals. Raw materials are formed into tile shapes known as green tiles. The final process step in tile manufacturing is to fire green tiles in a kiln at temperatures exceeding 2,000 oF. Chlorine, fluorine, and sulfur are present in raw materials which convert to hydrogen chloride (HCl), hydrogen fluoride (HF), and sulfur dioxide (SO2) in the exhaust gas. These pollutants are regulated by the NESHAP standard for clay ceramics manufacturing and must be removed before exhausting to the atmosphere. Envitech’s quencher and packed bed absorber is used to neutralize and remove acid gases from the tile kiln exhaust. The scrubber has high up-time to maximize production. It is generally smaller, simpler to operate, and achieves higher removal efficiencies than alternative dry technologies.

NESHAP MACT Standard: Clay Ceramics Manufacturing

Exhaust Sources:

- Ceramic Tile Kiln

Pollutants:

- Acid gas: HCl, HF, SO2

- Particulate

Equipment: