There are several industrial processes that face the challenge of meeting increasingly aggressive metals emission standards. In many cases these standards exceed the capability of existing air pollution control equipment which can include bag-houses and packed bed absorbers. Some of these processes include:

-

Secondary lead smelters

-

Lead refining

-

Refinery sludge incinerators

-

Geothermal energy plants

Some of the metals of concern can include mercury, arsenic, lead, cadmium, nickel and others, depending on the process. To achieve more stringent metals emission standards, three features should be designed into the air pollution control system.

-

Removal of the bulk particulate load

-

Sub-cooling the gas

-

Wet Electrostatic Precipitator (WESP) for polishing

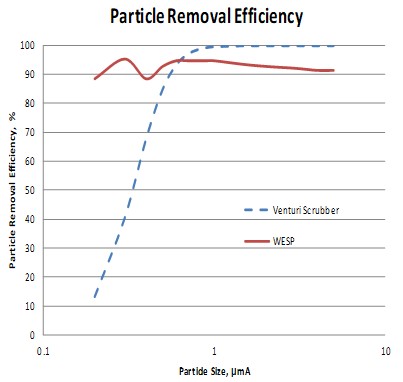

Removal of the bulk particulate load - Removal of the bulk particulate load may be required if there is a high particulate concentration from the upstream process. This will be the case for secondary lead smelters, lead refining, and refinery sludge incinerators. Geothermal energy plants will not have this requirement. A bag-house will be used for secondary lead smelters and lead refining. A wet Venturi scrubber system can be used for refinery sludge incinerators Removal of the bulk particulate minimizes space-charge effects inside the WESP. Space-charge effects occur when particles interact and repel each other. This reduces WESP performance because it interferes with the migration of charged particle to the tube wall for collection.

Removal of the bulk particulate load - Removal of the bulk particulate load may be required if there is a high particulate concentration from the upstream process. This will be the case for secondary lead smelters, lead refining, and refinery sludge incinerators. Geothermal energy plants will not have this requirement. A bag-house will be used for secondary lead smelters and lead refining. A wet Venturi scrubber system can be used for refinery sludge incinerators Removal of the bulk particulate minimizes space-charge effects inside the WESP. Space-charge effects occur when particles interact and repel each other. This reduces WESP performance because it interferes with the migration of charged particle to the tube wall for collection.

Sub-cooling the gas - Some of the volatile metals may be in the vapor phase when they pass through a bag-house at higher temperature. In this case they will pass right through the bag-house and will not be collected. Sub-cooling the gas is done after the bag-house and uses a condenser/absorber to cool the gas below the saturation temperature. Sub-cooling is beneficial because it condenses as much of the volatile metals as possible so they can later be removed as particulate. In the case where a Venturi is used to remove bulk particulate, like for a refinery sludge incinerator, it has the added benefit of condensing water onto the particulate and condensed metals. This increases their diameter making them easier to remove in a Venturi scrubber. Sub-cooling also reduces the gas volume, which helps to reduce the size and cost of a downstream WESP.

Wet Electrostatic Precipitator (WESP) for polishing - A wet electrostatic precipitator is used as a final particulate polishing stage. The performance is relatively independent of the particle size so it is highly effective at sub-micron particulate control. In some cases, a condenser/absorber (C/A) for sub-cooling can be integrated into the conditioning section of an upflow WESP. This was successfully done at a secondary lead smelter downstream of bag-house. The C/A was also used to neutralize SO2 in the gas stream. The integrated C/A and WESP achieved > 98% removal of arsenic and > 92% removal of lead and other condensed metals after the bag-house. This substantially reduced the plants cancer risk index and helped to meet more stringent fence line lead emission standards.

To download a free white paper on wet electrostatic precipitator for a secondary lead smelter, click the link below.

To view a free wet electrostatic precipitator video, click on the link below.

owing pollutants.

owing pollutants. control to meet the more stringent standards. Envitech has had success achieving higher removal efficiencies by integrating an add-on particulate polishing package (PPP) into incinerator wet scrubber systems. The PPP is comprised of a skid mounted package that provides slight reheat of the gas temperature to slightly above saturation in combination with a filter system. The reheat eliminates the potential for condensation build-up in the filters.

control to meet the more stringent standards. Envitech has had success achieving higher removal efficiencies by integrating an add-on particulate polishing package (PPP) into incinerator wet scrubber systems. The PPP is comprised of a skid mounted package that provides slight reheat of the gas temperature to slightly above saturation in combination with a filter system. The reheat eliminates the potential for condensation build-up in the filters.

Envitech is often asked to make recommendations for particulate removal on a wide range of industrial applications. This might entail deciding if a

Envitech is often asked to make recommendations for particulate removal on a wide range of industrial applications. This might entail deciding if a  There are several test methods for determining the particle size distribution, however the test method must determine the aerodynamic particle size to adequately predict the Venturi performance. The most common method for determining the aerodynamic particle size is to use a cascade impactor. This can be a challenging test because the inlet gas stream may be at high temperature and contain a high particulate loading and moisture content. It is important to select a testing company that has experience with this type of environment. Below is a references from the

There are several test methods for determining the particle size distribution, however the test method must determine the aerodynamic particle size to adequately predict the Venturi performance. The most common method for determining the aerodynamic particle size is to use a cascade impactor. This can be a challenging test because the inlet gas stream may be at high temperature and contain a high particulate loading and moisture content. It is important to select a testing company that has experience with this type of environment. Below is a references from the