There are several different waste incinerator source categories controlled by EPA standards under the Clean Air Act (CAA). These include hazardous waste combustors (HWC), sewage sludge incinerators (SSI), municipal solid waste (MSW) incinerators, commercial and industrial solid waste (CISWI) incinerators, and Hospital, Medical, and Infectious Waste Incinerators (HMIWI). Each incinerator type has its own Maximum Achievable Control Technology (MACT) standard which establishes technology based limits for emitted HAPs. MACT standards are part of the National Emission Standards for

There are several different waste incinerator source categories controlled by EPA standards under the Clean Air Act (CAA). These include hazardous waste combustors (HWC), sewage sludge incinerators (SSI), municipal solid waste (MSW) incinerators, commercial and industrial solid waste (CISWI) incinerators, and Hospital, Medical, and Infectious Waste Incinerators (HMIWI). Each incinerator type has its own Maximum Achievable Control Technology (MACT) standard which establishes technology based limits for emitted HAPs. MACT standards are part of the National Emission Standards for

Hazardous Air Pollutants (NESHAP) and are applied to source categories that pose adverse risk to human health by the emission of hazardous air pollutants (HAPs). The HMIWI MACT standard for medical waste incinerators is the most challenging of the incinerator source categories. This standard controls particulate (PM), hydrogen chloride (HCl), sulfur dioxide (SO2), lead (Pb), cadmium (Cd), mercury (Hg), dioxins/furans (D/F), nitrous oxide (NOx), and carbon monoxide (CO). Emission limits depend on the incinerator size and weather it is a new or existing source. Small incinerators are less than 200 lb/hr of waste throughput, medium incinerators are between 200 lb/hr and 500 lb/hr, and large incinerators are greater than 500 lb/hr.

Envitech recently completed a project for two medical waste incinerators at a Midwest research facility. These are the first new medical waste incinerators installed in the United States since Envitech installed a 525 lb/hr medical waste incinerator at a research facility in Galveston, TX in 2013.

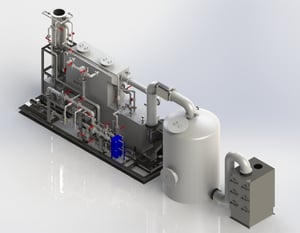

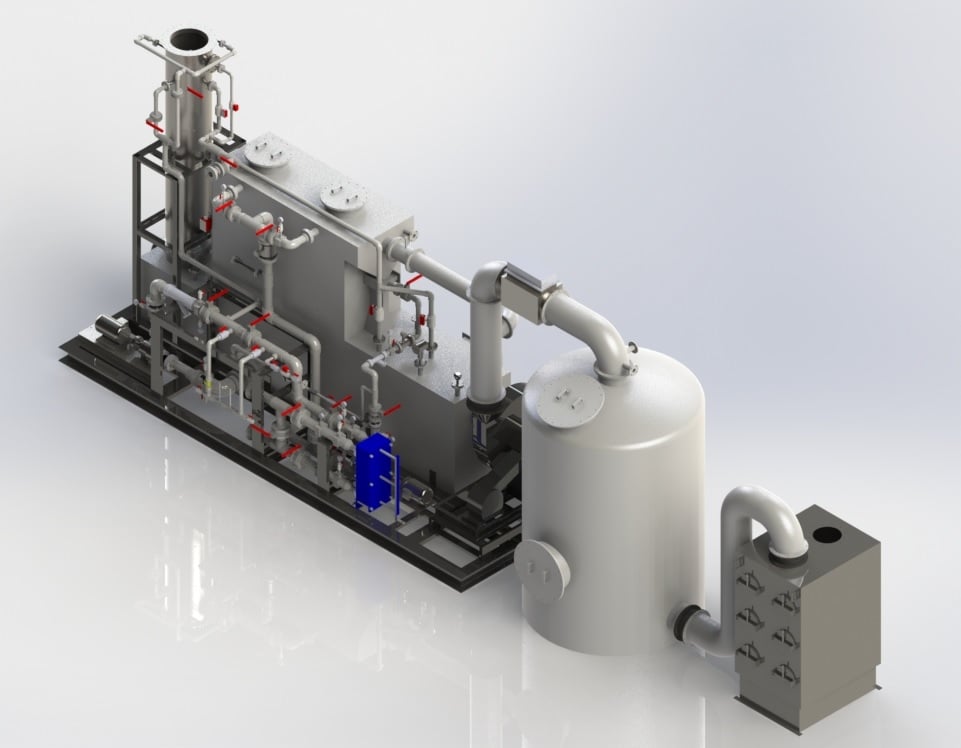

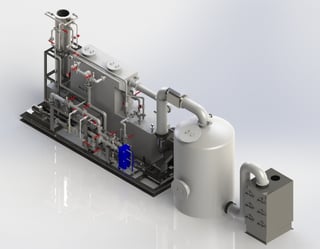

The scope of supply includes two medical waste incinerator scrubbers and a water treatment system to treat the blowdown from both incinerators. The incinerators are permitted as new, medium size incinerators. Ozone injection is integrated into the system to meet a NOx limit of 67 ppmv. The systems include pre-assembled pumps, piping, valves, and fittings to minimize installation time and cost. The pre-assembly provides long term rigidity, consolidation of space, longer up-time, and improved safety for operators. A description of the process arrangement can be found in this link to an earlier blog post.

Stack testing was performed in June 2021 for both incinerators. Test results confirm the Envitech system reduced emissions well below MACT standard limits, providing a comfortable margin for compliance over the range of operating conditions and waste feed. Below is a summary of stack test performance.

| Parameter | Emission Limit | Result, %Limit |

| PM | < 0.0095 gr/dscf | 17.9 |

| Pb | < 0.018 mg/dscfm | 8.9 |

| Cd | < 0.0098 mg/dscfm | 4.6 |

| Hg | < 0.0035 mg/dscfm | 25.7 |

| D/F | < 0.014 ng/dscm TEQ | < 1 |

| HCl | < 7.7 ppmv dry | < 1 |

| SO2 | < 1.4 ppmv | < 1 |

| NOx | < 67 ppmv dry | 24 |

Click on the link below to download literature on medical waste incinerator scrubbers.

Wet scrubbers are used to control hazardous air pollutants (HAPs) on many hospital, medical, and infectious waste incinerators (HMIWI). The Maximum Available Control Technology (MACT) standard for these incinerators was revised and became final in 2009. The new standard has the lowest emission limits for incinerators today. The limits exceeded the capability of systems designed to the previous standard with respect to particulate matter (PM), lead (Pd), cadmium (Cd), mercury (Hg), and dioxin/furans (D/F). By 2014 all existing medical waste incinerators were either shut down or upgraded to comply with the new standard. Envitech successfully upgraded four existing medical waste incinerators. A

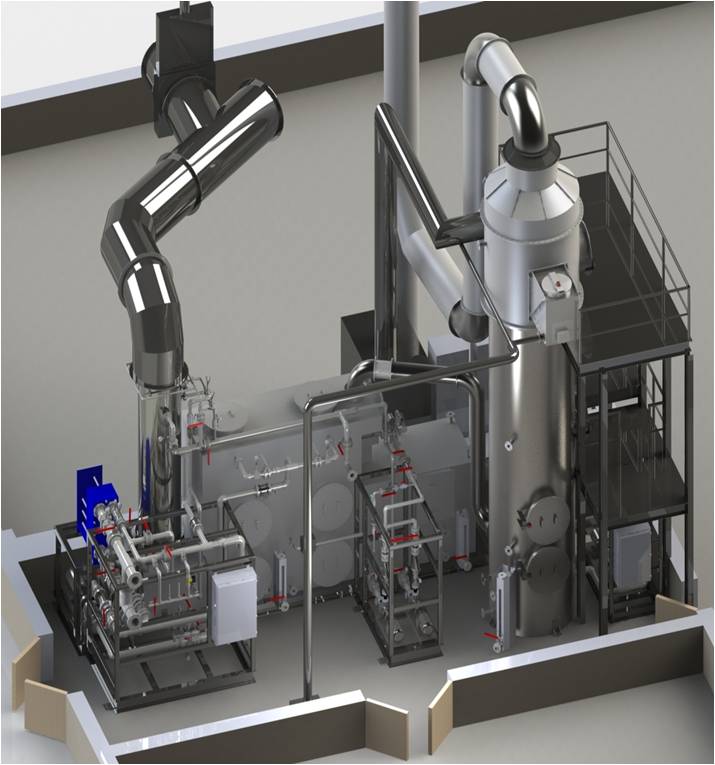

Wet scrubbers are used to control hazardous air pollutants (HAPs) on many hospital, medical, and infectious waste incinerators (HMIWI). The Maximum Available Control Technology (MACT) standard for these incinerators was revised and became final in 2009. The new standard has the lowest emission limits for incinerators today. The limits exceeded the capability of systems designed to the previous standard with respect to particulate matter (PM), lead (Pd), cadmium (Cd), mercury (Hg), and dioxin/furans (D/F). By 2014 all existing medical waste incinerators were either shut down or upgraded to comply with the new standard. Envitech successfully upgraded four existing medical waste incinerators. A  rward will be new medical waste incinerators which have even more stringent, ultra-low emission limits. Building a new incinerator requires critical decisions on control technologies and permitting. The IT3/HWC paper reviews these issues for specific HAPs and discuss trade-offs between permitting a new medium size incinerator versus a large incinerator. An example is provided of an air pollution control system meeting the emission requirements for a new large medical waste incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. Envitech is also building gas cleaning systems for two new medium size medical waste incinerators for a research facility which integrate NOx control using ozone injection.

rward will be new medical waste incinerators which have even more stringent, ultra-low emission limits. Building a new incinerator requires critical decisions on control technologies and permitting. The IT3/HWC paper reviews these issues for specific HAPs and discuss trade-offs between permitting a new medium size incinerator versus a large incinerator. An example is provided of an air pollution control system meeting the emission requirements for a new large medical waste incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. Envitech is also building gas cleaning systems for two new medium size medical waste incinerators for a research facility which integrate NOx control using ozone injection.

In 2009, the US EPA revised the emission limits for the Hospital, Medical, and Infectious Waste Incinerator (

In 2009, the US EPA revised the emission limits for the Hospital, Medical, and Infectious Waste Incinerator (

paper at the International Conference of Thermal Treatment

paper at the International Conference of Thermal Treatment  Technologies and Hazardous Waste Combustors (

Technologies and Hazardous Waste Combustors ( Pb reduction for a new large medical waste incinerator is even more dramatic. The emission limit is a mere 0.06% of the 1997 standard. Compared to an existing system permitted to the new standard, a large new medical waste incinerator must emit 2 orders of magnitude less Pb.

Pb reduction for a new large medical waste incinerator is even more dramatic. The emission limit is a mere 0.06% of the 1997 standard. Compared to an existing system permitted to the new standard, a large new medical waste incinerator must emit 2 orders of magnitude less Pb. ogram

ogram

incinerator. The incinerator exhaust is ducted to a metal quencher (shown in the foreground). The hot gas enters the top of the quencher and flows vertically downward. The gas then elbows into the bottom of a vertical packed bed scrubber (shown in the background). The gas passes upward through the packed bed as re-circulated water flows downward, counter-current to the gas from the top of the packed bed. Water from the quencher and packed bed is collected in the sump and re-circulated back to the quencher and packed bed. An entrainment separator at the top of the scrubber removes entrained water droplets. After exiting the scrubber vessel, an interconnect duct transports the gas to a induced draft fan located at grade.

incinerator. The incinerator exhaust is ducted to a metal quencher (shown in the foreground). The hot gas enters the top of the quencher and flows vertically downward. The gas then elbows into the bottom of a vertical packed bed scrubber (shown in the background). The gas passes upward through the packed bed as re-circulated water flows downward, counter-current to the gas from the top of the packed bed. Water from the quencher and packed bed is collected in the sump and re-circulated back to the quencher and packed bed. An entrainment separator at the top of the scrubber removes entrained water droplets. After exiting the scrubber vessel, an interconnect duct transports the gas to a induced draft fan located at grade.