A catalyst production facility operates a calciner that generates a small stream of hot dirty gas. The exhaust is cleaned using a particulate/SO2 scrubber followed by a vertical entrainment separator. The configuration is problematic for operation. The scrubber requires a long duct run from near grade to the scrubber inlet flange. There is a U-shaped bend to the inlet flange. Particulate condenses in the duct and plugs over time. The process is routinely shut down to clean out accumulated material. This limits production capacity. The customer sought to redesign the scrubber to increase production while maintaining as much of the original equipment as possible.

A catalyst production facility operates a calciner that generates a small stream of hot dirty gas. The exhaust is cleaned using a particulate/SO2 scrubber followed by a vertical entrainment separator. The configuration is problematic for operation. The scrubber requires a long duct run from near grade to the scrubber inlet flange. There is a U-shaped bend to the inlet flange. Particulate condenses in the duct and plugs over time. The process is routinely shut down to clean out accumulated material. This limits production capacity. The customer sought to redesign the scrubber to increase production while maintaining as much of the original equipment as possible.

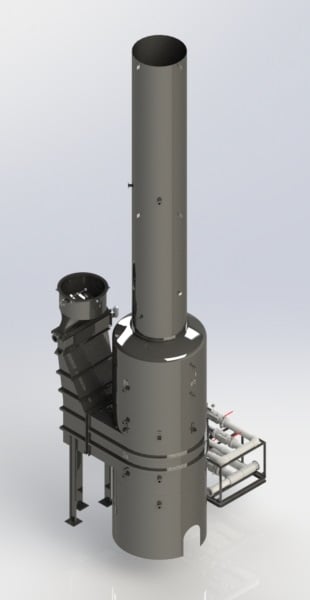

The customer selected Envitech to redesign and supply a scrubber to be retrofit into the existing system. The scrubber inlet was replaced with a high efficiency Hastelloy Venturi scrubber for particulate removal. The Venturi length was significantly decreased and oriented at an angle to the entrainment separator inlet. The shorter distance and angled orientation significantly reduced the duct run from the calciner outlet to the scrubber inlet, minimizing fouling potential.

The top of the entrainment separator was replaced with a packed bed absorber to neutralize and remove SO2. Structural modifications to the existing vessel ensures the new packed bed is well supported.

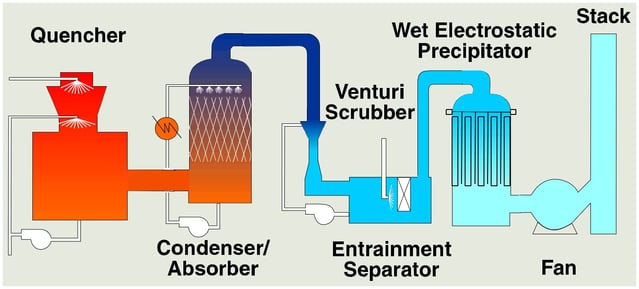

After the Venturi, the gas enters the bottom of the packed bed and travels vertically upward, counter current to downward flowing water. Excess water from the Venturi and the packed bed collects in a common sump. Caustic solution injected into the recirculation line neutralizes acid gases. Liquid recirculates back to the Venturi throat and top of the packed bed. The gas passes through a vertical entrainment separator above the packing to remove water droplets before exiting the system.

The scrubber was put into service in early 2021. A continuous emissions monitoring system (CEMS) confirms emission limits are met. The duct clean out time has been reduced from 24 to 36 hours to < 1 hour. System uptime has improved from < 60% to > 80%, enabling higher production capacity. The Venturi scrubber is significantly smaller in size, making replacement cost less expensive. The scrubber is designed to meet the process conditions below:

- Flow rate: < 1,000 acfm

- Inlet Temp, 400 oF

- Particulate removal: > 99.8%

- SO2 removal: > 99.9%

Click on the link below to download literature about the catalyst Calciner scrubber.

BP Amoco was engaged in expanding production capacity for purified terephthalic acid (PTA) at the CAPCO 6 and Zhuhai 1 petrochemical plants in China. PTA is used in the manufacture of polyester resin and polyethylene terephthalate (PET) plastic bottles. It is also widely used in the pharmaceutical, food, textile and packaging industries. The expansion projects were part of efforts to achieve process simplifications and lower capital costs. Project goals were to reduce plot area and the number of equipment pieces by 40%

BP Amoco was engaged in expanding production capacity for purified terephthalic acid (PTA) at the CAPCO 6 and Zhuhai 1 petrochemical plants in China. PTA is used in the manufacture of polyester resin and polyethylene terephthalate (PET) plastic bottles. It is also widely used in the pharmaceutical, food, textile and packaging industries. The expansion projects were part of efforts to achieve process simplifications and lower capital costs. Project goals were to reduce plot area and the number of equipment pieces by 40% The customer selected a custom engineered Envitech horizonal quencher. The material of construction is Hastelloy C276 to provide corrosion resistance at high inlet temperatures. A proprietary internal water injection and throat design splits the stream inside the vessel to ensure turbulence for mixing gases and water. Gases accelerate through the throat areas in combination with a recirculated water spray system. A small pressure drop cools gases over a wide flow rate operating range and minimizes the number of nozzles. The water spray header is removable to facilitate nozzle replacement and maintenance. The vessel is 13 feet in diameter in a horizontal arrangement. This allows the quencher to be shop fabricated so that inspection and quality assurance are done in a controlled environment. The unit is shipped as one piece.

The customer selected a custom engineered Envitech horizonal quencher. The material of construction is Hastelloy C276 to provide corrosion resistance at high inlet temperatures. A proprietary internal water injection and throat design splits the stream inside the vessel to ensure turbulence for mixing gases and water. Gases accelerate through the throat areas in combination with a recirculated water spray system. A small pressure drop cools gases over a wide flow rate operating range and minimizes the number of nozzles. The water spray header is removable to facilitate nozzle replacement and maintenance. The vessel is 13 feet in diameter in a horizontal arrangement. This allows the quencher to be shop fabricated so that inspection and quality assurance are done in a controlled environment. The unit is shipped as one piece.

into a consistent granular media. The media is used as a natural microbial carrier to inoculate millions of acres of food crops each year. The transformation process relies on drying harvested material in industrial rotary dryers. A fraction of the material becomes entrained in the flue gas as particulate emissions. The facility is expanding operations to double the capacity. A scrubber solution is needed to reduce total plant particulate emissions.

into a consistent granular media. The media is used as a natural microbial carrier to inoculate millions of acres of food crops each year. The transformation process relies on drying harvested material in industrial rotary dryers. A fraction of the material becomes entrained in the flue gas as particulate emissions. The facility is expanding operations to double the capacity. A scrubber solution is needed to reduce total plant particulate emissions. ers. The scrubbers are comprised of a variable throat Venturi scrubber and a chevron style entrainment separator mounted on an equipment skid. The scope of supply for each scrubber includes a control system, re-circulation pump with pre-assembled piping, valves and fittings. Instruments are pre-mounted in the piping where possible and pre-wired to a junction box on the skid. The horizontal configuration provides a compact design to fit inside the building with easy maintenance access to valves and instruments.

ers. The scrubbers are comprised of a variable throat Venturi scrubber and a chevron style entrainment separator mounted on an equipment skid. The scope of supply for each scrubber includes a control system, re-circulation pump with pre-assembled piping, valves and fittings. Instruments are pre-mounted in the piping where possible and pre-wired to a junction box on the skid. The horizontal configuration provides a compact design to fit inside the building with easy maintenance access to valves and instruments.

needed to remove particulate from a chlorine gas stream that originates in the anode compartments of electrolytic cells that produce magnesium metal. A significant portion of the particulate is less than 1 micron in size, making it difficult to remove.

needed to remove particulate from a chlorine gas stream that originates in the anode compartments of electrolytic cells that produce magnesium metal. A significant portion of the particulate is less than 1 micron in size, making it difficult to remove. tic (FRP) Venturi scrubber and horizontal chevron style entrainment separator. Additional scope of supply includes instruments, pre-assembled pump skid with redundant titanium pumps (1 operating and 1 spare), pre-assembled CPVC piping, redundant fans with titanium wheel and housing, interconnect FRP ductwork, dampers, and equipment skid and platforms.

tic (FRP) Venturi scrubber and horizontal chevron style entrainment separator. Additional scope of supply includes instruments, pre-assembled pump skid with redundant titanium pumps (1 operating and 1 spare), pre-assembled CPVC piping, redundant fans with titanium wheel and housing, interconnect FRP ductwork, dampers, and equipment skid and platforms.

Banbury mixers are used, for instance, to compound rubber material for manufacturing automobile tires. Uncontrolled fumes from the mixers can create a nuisance by settling around the facility. Envitech’s Venturi collision scrubber has been used to control these fumes. The figure on the right shows a typical Venturi collision scrubber for a 25,000 cfm mixer exhaust. The scrubber separates the exhaust into two streams internal to the scrubber. The streams are then directed to two opposing Venturi throats. Recirculated water injected into each throat is atomized into fine droplets as the gas is accelerated. Fume particles and droplets collide and are captured by the atomized water as the steams are recombined into a third Venturi throat. A diffusion section redistributes the gas to a horizontal chevron style mist eliminator to remove entrained water droplets. Water is collected and drained into a common sump and recirculated back to the Venturi throats. A blowdown stream purges the collected material.

Banbury mixers are used, for instance, to compound rubber material for manufacturing automobile tires. Uncontrolled fumes from the mixers can create a nuisance by settling around the facility. Envitech’s Venturi collision scrubber has been used to control these fumes. The figure on the right shows a typical Venturi collision scrubber for a 25,000 cfm mixer exhaust. The scrubber separates the exhaust into two streams internal to the scrubber. The streams are then directed to two opposing Venturi throats. Recirculated water injected into each throat is atomized into fine droplets as the gas is accelerated. Fume particles and droplets collide and are captured by the atomized water as the steams are recombined into a third Venturi throat. A diffusion section redistributes the gas to a horizontal chevron style mist eliminator to remove entrained water droplets. Water is collected and drained into a common sump and recirculated back to the Venturi throats. A blowdown stream purges the collected material.

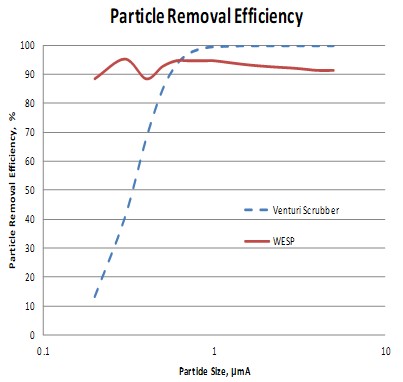

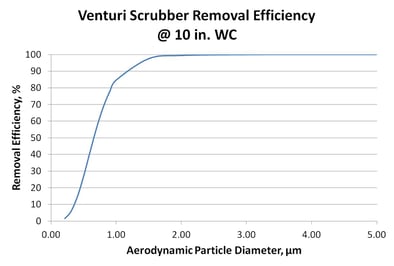

Venturi. It indicates that nearly all particles > 2 micron in size are removed by the Venturi. Performance drops off dramatically, however, for smaller particles. Mechanisms for particulate removal by a Venturi scrubber are discussed in more detail in an earlier

Venturi. It indicates that nearly all particles > 2 micron in size are removed by the Venturi. Performance drops off dramatically, however, for smaller particles. Mechanisms for particulate removal by a Venturi scrubber are discussed in more detail in an earlier  pressure drop over a minimum and maximum gas flow rate. The damper position is governed by proportional-integral-derivative control based on the differential pressure across the throat.

pressure drop over a minimum and maximum gas flow rate. The damper position is governed by proportional-integral-derivative control based on the differential pressure across the throat.

In 2009, the US EPA revised the emission limits for the Hospital, Medical, and Infectious Waste Incinerator (

In 2009, the US EPA revised the emission limits for the Hospital, Medical, and Infectious Waste Incinerator (