A Venturi scrubber is a common air pollution control device that is used to remove particulate. Because it is a wet scrubber, collected particulate is purged in a liquid discharge stream called the blowdown.

A Venturi scrubber is a common air pollution control device that is used to remove particulate. Because it is a wet scrubber, collected particulate is purged in a liquid discharge stream called the blowdown.

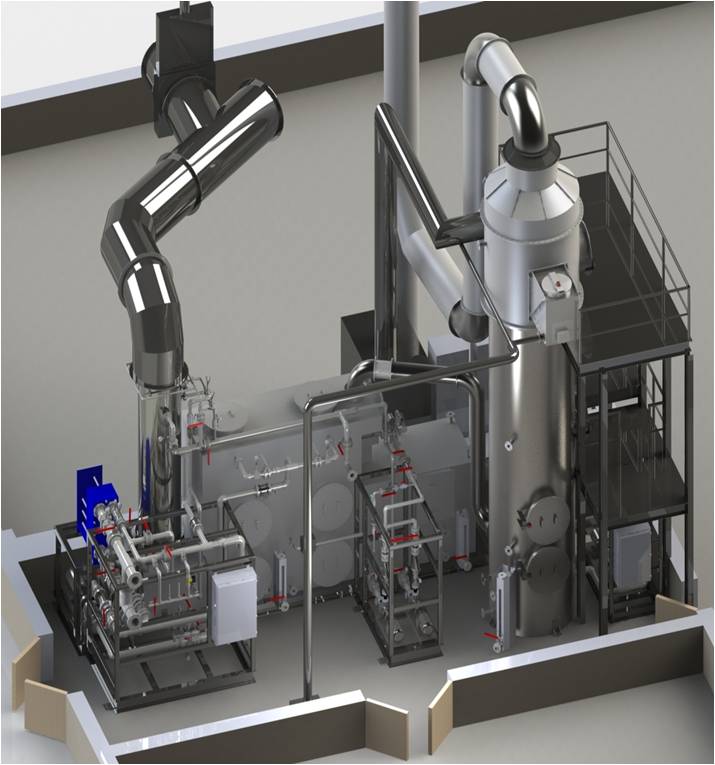

Venturi scrubbers are commonly used for industrial dryer applications (see photo). They have a relatively low inlet temperature or might have sticky particulate which prevent the use of a bag-house. Typical dryer applications include coal dryers, pot ash mining, CPVC plastics manufacturing, bio-solids sludge drying, or salt production. Venturi scrubbers are also used in insulation or glass manufacturing, magnesium mining, and hazardous and medical waste incineration.

It is important to saturate or pre-cool the gas before entering the Venturi throat to minimize evaporation. That is because during evaporation, water molecules leave the water droplet surfaces which push particles away from the droplets and reduce collection efficiency. It is also important to keep the inlet walls of the Venturi wetted to avoid fouling from wet-dry line interface.

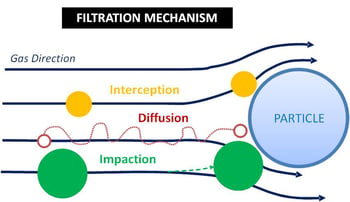

In accordance with Bernoulli's equation, inlet gas accelerates at the converging section of the Venturi throat, increasing gas-liquid contact. As water is injected perpendicular to the gas flow in the throat, the accelerated gas particles are captured by water droplets upon collision. Three mechanisms account for collection in a Venturi which is summarized below. The adjacent graphic scrubber illustrates the three mechanisms.

- Diffusion – Particle is so small its path is erratic due to Brownian motion.

- Interception – Particle follows streamline around droplet, makes contact if within a particle radius.

- Impaction – Particle’s inertia cause it to leave stream line and impact the droplet.

Impaction is the dominant collection mechanism for large particles, greater than 15 microns. They can be collected with efficiency greater than 99%. Diffusion and interception are more prevalent for smaller particles. Collection efficiency is lower for these particles because their small size increases the probability they will flow around the water droplets and avoid collection.

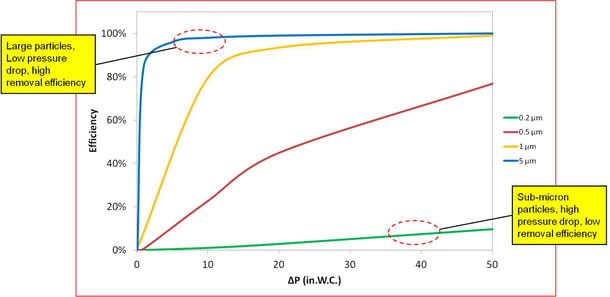

The graph below illustrates the impact of particle size on collection efficiency. The vertical axis is collection efficiency and the horizontal axis is pressure drop. The curves represent different particle sizes ranging from 0.2 to 5 microns. It can be seen that collection efficiency increases for larger particles and higher pressure drops. The net result is overall collection efficiency is dependent on the aerodynamic particle size distribution (PSD).

After particle collection in the Venturi throat, the resulting droplets aggregate through the diverging section and are separated from the process gas by the mist eliminator (ME) in the entrainment separator (ES). The ability of the mist eliminator to remove water droplets from the gas stream can have a significant impact on the scrubber performance. Any water droplets that "escape" the ME will carry entrained particulate and increase the measured outlet emissions. A more detailed discussion on mist elimination can be found in the previous blog post on “Improving Entrainment Separator Design”.

To download a free case study on a Venturi scrubber used to remove particulate from a CPVC dryer.

ogram

ogram

copper resources challenged by high levels of arsenic. Mining operations may incur penalties for arsenic in concentrates that exceed a certain amount. As ore with low levels of arsenic is depleted, these penalties will continue to rise.

copper resources challenged by high levels of arsenic. Mining operations may incur penalties for arsenic in concentrates that exceed a certain amount. As ore with low levels of arsenic is depleted, these penalties will continue to rise.

standard. The compliance dates for these rules are fast approaching. Facilities with existing equipment must demonstrate compliance to the new standards by October 2014. Envitech is already under contract with several facilities to retro-fit existing medical waste incinerator scrubbers with add-on control equipment to meet the new standards.

standard. The compliance dates for these rules are fast approaching. Facilities with existing equipment must demonstrate compliance to the new standards by October 2014. Envitech is already under contract with several facilities to retro-fit existing medical waste incinerator scrubbers with add-on control equipment to meet the new standards.  Stack emissions must meet substantially lower limits for Cd, Pb, and Hg. In many cases, this requires add-on controls capable of greater than 90% removal of sub-micron condensed metals. Most facilities are putting on a re-heat and filter package to remove the condensed metals. A few will use wet electrostatic precipitators (WESP) which are more expensive. The ability to meet the new rules using a re-heat and filter package has been demonstrated for lead and cadmium on a commercial and industrial waste incinerator (CISWI). The WESP capability has been demonstrated for reduction of lead emission achieved at a

Stack emissions must meet substantially lower limits for Cd, Pb, and Hg. In many cases, this requires add-on controls capable of greater than 90% removal of sub-micron condensed metals. Most facilities are putting on a re-heat and filter package to remove the condensed metals. A few will use wet electrostatic precipitators (WESP) which are more expensive. The ability to meet the new rules using a re-heat and filter package has been demonstrated for lead and cadmium on a commercial and industrial waste incinerator (CISWI). The WESP capability has been demonstrated for reduction of lead emission achieved at a

Kemper County Coal Gasificaton Integrated Combined Cycle (IGCC) Project. The project is a 582-megawatt power plant currently under construction. The facility will convert locally mined lignite coal into energy using a state of the art coal gasification process call Transport Integrated Gasification, or TRIGTM. The process enables a 65% CO2 reduction making green house gas emissions equivalent to similar size natural gas combined cycle power plant

Kemper County Coal Gasificaton Integrated Combined Cycle (IGCC) Project. The project is a 582-megawatt power plant currently under construction. The facility will convert locally mined lignite coal into energy using a state of the art coal gasification process call Transport Integrated Gasification, or TRIGTM. The process enables a 65% CO2 reduction making green house gas emissions equivalent to similar size natural gas combined cycle power plant

in Kemper County Mississippi is being built. The process uses locally mined lignite coal for fuel which contains 40% moisture. The coal must be dried before it is converted to syngas in the gasifier.

in Kemper County Mississippi is being built. The process uses locally mined lignite coal for fuel which contains 40% moisture. The coal must be dried before it is converted to syngas in the gasifier.

is upgrading a sulfite pulping mill in Eastern Canada to incorporate a new red liquor recovery boiler for power generation. The boiler system increases annual green energy production by up to 40-megawatts, reduces sulfur dioxide emissions by 70%, and increases annual production capacity of specialty cellulose by 5,000 metric tonnes. The off-gas from the recovery boiler contains a high concentration of SO2 which needs to be recovered for re-use in the production process.

is upgrading a sulfite pulping mill in Eastern Canada to incorporate a new red liquor recovery boiler for power generation. The boiler system increases annual green energy production by up to 40-megawatts, reduces sulfur dioxide emissions by 70%, and increases annual production capacity of specialty cellulose by 5,000 metric tonnes. The off-gas from the recovery boiler contains a high concentration of SO2 which needs to be recovered for re-use in the production process.