There are several different waste incinerator source categories controlled by EPA standards under the Clean Air Act (CAA). These include hazardous waste combustors (HWC), sewage sludge incinerators (SSI), municipal solid waste (MSW) incinerators, commercial and industrial solid waste (CISWI) incinerators, and Hospital, Medical, and Infectious Waste Incinerators (HMIWI). Each incinerator type has its own Maximum Achievable Control Technology (MACT) standard which establishes technology based limits for emitted HAPs. MACT standards are part of the National Emission Standards for

There are several different waste incinerator source categories controlled by EPA standards under the Clean Air Act (CAA). These include hazardous waste combustors (HWC), sewage sludge incinerators (SSI), municipal solid waste (MSW) incinerators, commercial and industrial solid waste (CISWI) incinerators, and Hospital, Medical, and Infectious Waste Incinerators (HMIWI). Each incinerator type has its own Maximum Achievable Control Technology (MACT) standard which establishes technology based limits for emitted HAPs. MACT standards are part of the National Emission Standards for

Hazardous Air Pollutants (NESHAP) and are applied to source categories that pose adverse risk to human health by the emission of hazardous air pollutants (HAPs). The HMIWI MACT standard for medical waste incinerators is the most challenging of the incinerator source categories. This standard controls particulate (PM), hydrogen chloride (HCl), sulfur dioxide (SO2), lead (Pb), cadmium (Cd), mercury (Hg), dioxins/furans (D/F), nitrous oxide (NOx), and carbon monoxide (CO). Emission limits depend on the incinerator size and weather it is a new or existing source. Small incinerators are less than 200 lb/hr of waste throughput, medium incinerators are between 200 lb/hr and 500 lb/hr, and large incinerators are greater than 500 lb/hr.

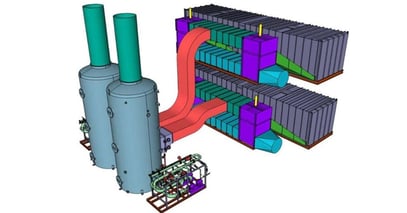

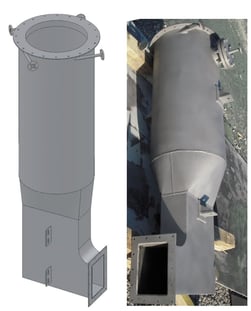

Envitech recently completed a project for two medical waste incinerators at a Midwest research facility. These are the first new medical waste incinerators installed in the United States since Envitech installed a 525 lb/hr medical waste incinerator at a research facility in Galveston, TX in 2013.

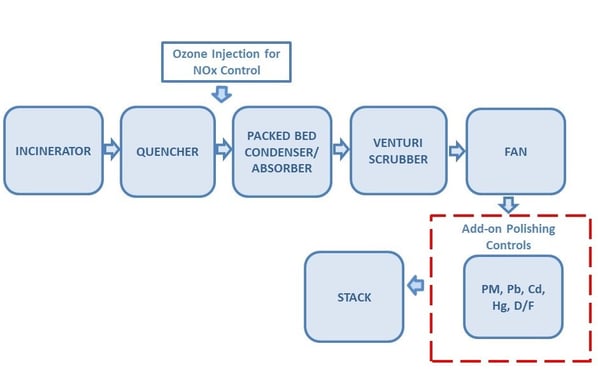

The scope of supply includes two medical waste incinerator scrubbers and a water treatment system to treat the blowdown from both incinerators. The incinerators are permitted as new, medium size incinerators. Ozone injection is integrated into the system to meet a NOx limit of 67 ppmv. The systems include pre-assembled pumps, piping, valves, and fittings to minimize installation time and cost. The pre-assembly provides long term rigidity, consolidation of space, longer up-time, and improved safety for operators. A description of the process arrangement can be found in this link to an earlier blog post.

Stack testing was performed in June 2021 for both incinerators. Test results confirm the Envitech system reduced emissions well below MACT standard limits, providing a comfortable margin for compliance over the range of operating conditions and waste feed. Below is a summary of stack test performance.

| Parameter | Emission Limit | Result, %Limit |

| PM | < 0.0095 gr/dscf | 17.9 |

| Pb | < 0.018 mg/dscfm | 8.9 |

| Cd | < 0.0098 mg/dscfm | 4.6 |

| Hg | < 0.0035 mg/dscfm | 25.7 |

| D/F | < 0.014 ng/dscm TEQ | < 1 |

| HCl | < 7.7 ppmv dry | < 1 |

| SO2 | < 1.4 ppmv | < 1 |

| NOx | < 67 ppmv dry | 24 |

Click on the link below to download literature on medical waste incinerator scrubbers.

removed after the RTO.

removed after the RTO.

Vintage Petroleum, LLC, a subsidiary of Occidental Petroleum Corporation operates oil and gas fields in Lost Hills, California, northwest of Bakersfield. The fields operate steam boilers that use nearby canal water. High concentrations of dissolved oxygen in the canal water caused excessive corrosion in the boilers.

Vintage Petroleum, LLC, a subsidiary of Occidental Petroleum Corporation operates oil and gas fields in Lost Hills, California, northwest of Bakersfield. The fields operate steam boilers that use nearby canal water. High concentrations of dissolved oxygen in the canal water caused excessive corrosion in the boilers.

nclosed to capture process emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) are released during shredding, including small amounts of halogenated compounds.

nclosed to capture process emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) are released during shredding, including small amounts of halogenated compounds.

(TO) that treats a rich stream of chlorinated compounds and an organic silicon compound. HCl and silicon dioxide (SiO2) particulate are formed during combustion. The exhaust is treated by a Hastelloy evaporative quencher followed by a caustic scrubber.

(TO) that treats a rich stream of chlorinated compounds and an organic silicon compound. HCl and silicon dioxide (SiO2) particulate are formed during combustion. The exhaust is treated by a Hastelloy evaporative quencher followed by a caustic scrubber.

The thermal oxidizers need a wet scrubber to neutralize and remove SO2. Flue gas entering the scrubber contain some sulfur trioxide (SO3) which is converted to sulfuric acid (H2SO4) in the quencher. Sulfuric acid is a submicron liquid aerosol that passes through the downstream packed bed absorber. Some facilities are now being regulated for H2SO4. This paper evaluates and compares candle filters versus wet electrostatic precipitators (WESP’s) for H2SO4 removal in these applications.

The thermal oxidizers need a wet scrubber to neutralize and remove SO2. Flue gas entering the scrubber contain some sulfur trioxide (SO3) which is converted to sulfuric acid (H2SO4) in the quencher. Sulfuric acid is a submicron liquid aerosol that passes through the downstream packed bed absorber. Some facilities are now being regulated for H2SO4. This paper evaluates and compares candle filters versus wet electrostatic precipitators (WESP’s) for H2SO4 removal in these applications. Waste water treatment facilities operating sewage sludge incinerators (SSI) can reduce sludge volume and disposal costs by combusting dewatered sewage sludge. Emissions are regulated by the US EPA Maximum Available Control Technology (MACT) standard 40 CFR Part 60 and 62 to control particulate, lead (Pb), cadmium (Cd), SO2, HCl, dioxins/furans, and mercury (Hg). Many SSI’s need a control device specifically for mercury. This paper evaluates two mercury control technologies: sulfur‐impregnated activated carbon and Gore sorbent polymer catalyst (SPC) modules. Several facilities have used sulfur-impregnated activated carbon but safety issues have arisen due to fires which have shut down some systems. The Gore SPC modules are a relatively new technology with at least seven installations. A comparison is made of capital cost, operating cost, mercury removal efficiency, fire and performance risks based on incineration of 3,000 lbs/hr of sewage sludge. Finally, an overview is provided for an Envitech SPC mercury control scrubber operating at one facility.

Waste water treatment facilities operating sewage sludge incinerators (SSI) can reduce sludge volume and disposal costs by combusting dewatered sewage sludge. Emissions are regulated by the US EPA Maximum Available Control Technology (MACT) standard 40 CFR Part 60 and 62 to control particulate, lead (Pb), cadmium (Cd), SO2, HCl, dioxins/furans, and mercury (Hg). Many SSI’s need a control device specifically for mercury. This paper evaluates two mercury control technologies: sulfur‐impregnated activated carbon and Gore sorbent polymer catalyst (SPC) modules. Several facilities have used sulfur-impregnated activated carbon but safety issues have arisen due to fires which have shut down some systems. The Gore SPC modules are a relatively new technology with at least seven installations. A comparison is made of capital cost, operating cost, mercury removal efficiency, fire and performance risks based on incineration of 3,000 lbs/hr of sewage sludge. Finally, an overview is provided for an Envitech SPC mercury control scrubber operating at one facility.

Hazardous Waste Combustors (

Hazardous Waste Combustors (

incinerator had been shut down due to safety issues with the granulated activated carbon (GAC) mercury control scrubber. The plant sought expert help to evaluate and recommend a technology solution to replace the GAC and to get the SSI back in operation.

incinerator had been shut down due to safety issues with the granulated activated carbon (GAC) mercury control scrubber. The plant sought expert help to evaluate and recommend a technology solution to replace the GAC and to get the SSI back in operation. available literature and data to establish a conservative but justifiable design inlet concentration with sufficient capacity to meet a more conservative design condition without structural changes to the equipment.

available literature and data to establish a conservative but justifiable design inlet concentration with sufficient capacity to meet a more conservative design condition without structural changes to the equipment.

An example was given for a captive incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. It’s one of the only systems in the United States permitted as a “new” medical waste incinerator according to the EPA HMIWI (hospital, medical, and infectious waste incinerator) MACT standard. This standard has the most challenging emission limits found in industry today. That is because in 2009 the EPA completed a source review and revised the standard based on a MACT-on-MACT analysis. Data used to set limits for each pollutant was individually based on waste feed and not incinerator/scrubber technology performance. This resulted in emission limit reductions for lead (Pb), cadmium (Cd), and dioxins/furans (D/F) that were orders of magnitude below the previous standard and below the capability of installed equipment. The impact of the new standard is discussed in greater detail in a

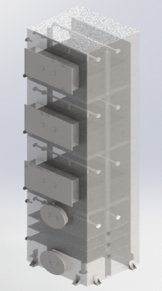

An example was given for a captive incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. It’s one of the only systems in the United States permitted as a “new” medical waste incinerator according to the EPA HMIWI (hospital, medical, and infectious waste incinerator) MACT standard. This standard has the most challenging emission limits found in industry today. That is because in 2009 the EPA completed a source review and revised the standard based on a MACT-on-MACT analysis. Data used to set limits for each pollutant was individually based on waste feed and not incinerator/scrubber technology performance. This resulted in emission limit reductions for lead (Pb), cadmium (Cd), and dioxins/furans (D/F) that were orders of magnitude below the previous standard and below the capability of installed equipment. The impact of the new standard is discussed in greater detail in a  Existing incinerators needed to be upgraded with add-on controls to meet the new standard. New incinerators need air pollution control equipment capable of extraordinarily high removal efficiency for particulate, Pb, Cd, and D/F. A new medium sized incinerator between 200 to 500 lb/hr capacity, has the additional challenge of meeting NOx. A medical waste incinerator can be tuned to a NOx limit of about 130 ppmv. The MACT standard limit for a new medium sized medical waste incinerator was set at 67 ppmv which means NOx abatement is required to guarantee compliance.

Existing incinerators needed to be upgraded with add-on controls to meet the new standard. New incinerators need air pollution control equipment capable of extraordinarily high removal efficiency for particulate, Pb, Cd, and D/F. A new medium sized incinerator between 200 to 500 lb/hr capacity, has the additional challenge of meeting NOx. A medical waste incinerator can be tuned to a NOx limit of about 130 ppmv. The MACT standard limit for a new medium sized medical waste incinerator was set at 67 ppmv which means NOx abatement is required to guarantee compliance.

e of the condenser/absorber is increased to provide sufficient residence time for ozone-NOx reactions to occur. Ozone is highly selective for NOx relative to other combustion products. The NOx is rapidly converted to water soluble species. NO and O3 react to form NO2 and O2. NO2 and O2 react to form N2O5 and O2. N2O5 and water react to form 2HNO3 which is readily absorbed with caustic solution.

e of the condenser/absorber is increased to provide sufficient residence time for ozone-NOx reactions to occur. Ozone is highly selective for NOx relative to other combustion products. The NOx is rapidly converted to water soluble species. NO and O3 react to form NO2 and O2. NO2 and O2 react to form N2O5 and O2. N2O5 and water react to form 2HNO3 which is readily absorbed with caustic solution.