In 2012 Envitech supplied a wet electrostatic precipitator (WESP) to remove submicron particulate and lead particles from a metal processing coating device. Envitech recently completed the start-up of a 2nd WESP for a different coating device at the same facility. Both systems are designed to remove greater than 95% of lead from low inlet concentrations. The inlet lead concentration is similar to that of a secondary lead smelter reverb furnace. Click on the link to read about the secondary lead smelter WESP.

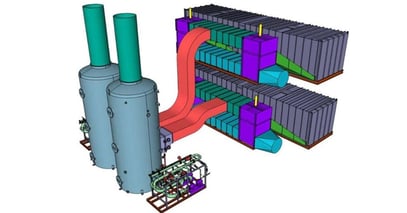

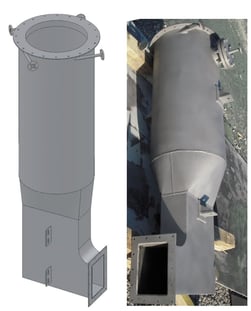

The scope of supply for the new system includes a WESP, instruments, control system, pre-assembled pump skids, interconnect ductwork, dampers, stack, access platforms, and make-up water treatment system. The WESP is a hexagonal tube, upflow design. The gas enters the bottom of the WESP and passes through the conditioning section to ensure the gas is fully saturated and evenly distributed to maximize collection efficiency.

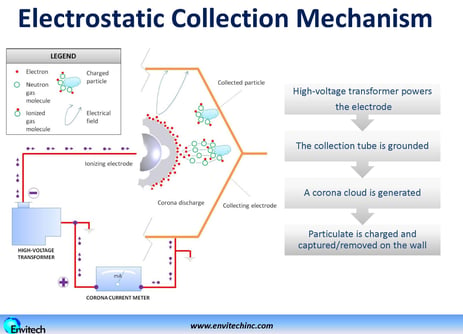

After the conditioning section, the gas enters the collection section. Electrostatic forces remove particles contained in the gas stream (see graphic below). The collector consists of grounded collector tubes and high voltage discharge electrodes. A voltage is applied to the discharge electrodes to both charge the particles and create a powerful electric field. The voltage on the discharge electrodes instigates a corona discharge of electrons from disks on the electrodes. The electrons move from the discharge disk to the collector tubes. Some of the electrons intercept particles in the gas stream which charges the particles. Once charged, particles migrate across the gas stream towards the grounded collector tubes. The particles are intermittently flushed with water from a spray header above the collector. Collected particulate containing lead fall by gravity from the tube walls into the WESP sump.

The outlet section is the last section and contains an entrainment separator to collect water drops that were entrained in the gas stream during the collector wash cycle. It also houses a support structure for the high voltage electrodes and wash water spray header.

The outlet section is the last section and contains an entrainment separator to collect water drops that were entrained in the gas stream during the collector wash cycle. It also houses a support structure for the high voltage electrodes and wash water spray header.

The system has a unique water and wastewater treatment system that mitigates the need for a hazardous liquid blowdown. An upstream water treatment system conditions the city water used to makeup losses associated with evaporation. The recirculation water to the system is filtered to remove hazardous particulate as a solid, greatly reducing the operating cost of disposal. The collection of the hazardous waste as a solid substantially reduced the facility hazardous disposal costs.

The facility reports high reliability and uptime with little intervention required to maintain operation and performance. The electrodes are rigid mast and firmly held in placed after alignment during start-up. Less than 2% of the electrodes have been replaced in seven years of operation. The WESP is designed to meet the below parameters:

- Inlet flow rate - 35,000 acfm

- Inlet temperature – 140°F

- Lead particulate performance guarantee – greater than 95% removal

Click on the link below to download a case study on this application.

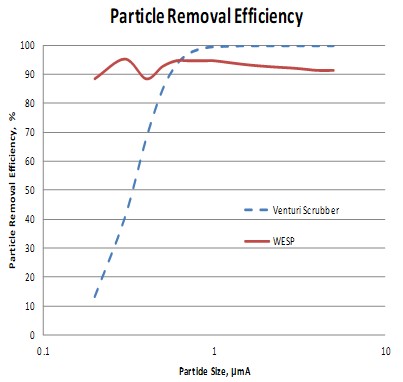

The adjacent figure illustrates WESP’s primary use. The graph shows removal efficiency on the vertical axis and particle size on the horizontal axis. The red curve shows typical WESP performance. The dotted blue curve shows typical Venturi scrubber performance. A comparison shows that a Venturi scrubber is highly effective at removing particles greater than 1 micron in size. However, performance drops off rapidly for particles below 1 micron. WESP performance is relatively immune to particle size and maintains high performance for particles below 1 micron. This capability is derived from the use of electrical forces for particle removal compared to a Venturi scrubber which uses mechanical forces. WESP’s are generally higher capital cost than Venturi scrubbers but lower operating cost. They are used in cases where performance cannot be achieved with a Venturi scrubber or other, lower cost control device.

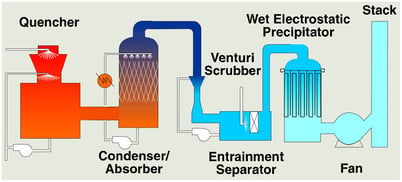

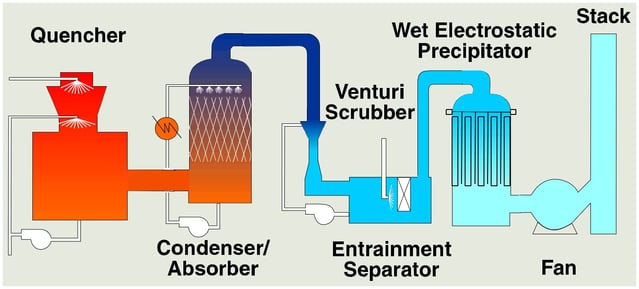

The adjacent figure illustrates WESP’s primary use. The graph shows removal efficiency on the vertical axis and particle size on the horizontal axis. The red curve shows typical WESP performance. The dotted blue curve shows typical Venturi scrubber performance. A comparison shows that a Venturi scrubber is highly effective at removing particles greater than 1 micron in size. However, performance drops off rapidly for particles below 1 micron. WESP performance is relatively immune to particle size and maintains high performance for particles below 1 micron. This capability is derived from the use of electrical forces for particle removal compared to a Venturi scrubber which uses mechanical forces. WESP’s are generally higher capital cost than Venturi scrubbers but lower operating cost. They are used in cases where performance cannot be achieved with a Venturi scrubber or other, lower cost control device. WESPs are often integrated with other control technologies and used as a polishing device at the end of a process. This is shown in the adjacent illustration for a typical waste incinerator. Perhaps the most important aspect to understand about WESP technology is the relationship between performance, size, and cost. Higher performance requires more collection area, larger footprint, and more cost. This is different than other control technologies like a Venturi scrubber or packed bed scrubber. For these devices, size and cost is primarily determined by the gas flow rate while operating cost is determined by performance. Size and cost for a WESP on the other hand is determined not only by gas flow rate but also removal efficiency. It is therefore important to have a good understanding of the range of inlet particulate concentrations and outlet emission limits. Specifying performance of 90%, 95%, or 99% removal will make a substantial difference on size and cost.

WESPs are often integrated with other control technologies and used as a polishing device at the end of a process. This is shown in the adjacent illustration for a typical waste incinerator. Perhaps the most important aspect to understand about WESP technology is the relationship between performance, size, and cost. Higher performance requires more collection area, larger footprint, and more cost. This is different than other control technologies like a Venturi scrubber or packed bed scrubber. For these devices, size and cost is primarily determined by the gas flow rate while operating cost is determined by performance. Size and cost for a WESP on the other hand is determined not only by gas flow rate but also removal efficiency. It is therefore important to have a good understanding of the range of inlet particulate concentrations and outlet emission limits. Specifying performance of 90%, 95%, or 99% removal will make a substantial difference on size and cost.

Vintage Petroleum, LLC, a subsidiary of Occidental Petroleum Corporation operates oil and gas fields in Lost Hills, California, northwest of Bakersfield. The fields operate steam boilers that use nearby canal water. High concentrations of dissolved oxygen in the canal water caused excessive corrosion in the boilers.

Vintage Petroleum, LLC, a subsidiary of Occidental Petroleum Corporation operates oil and gas fields in Lost Hills, California, northwest of Bakersfield. The fields operate steam boilers that use nearby canal water. High concentrations of dissolved oxygen in the canal water caused excessive corrosion in the boilers.

nclosed to capture process emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) are released during shredding, including small amounts of halogenated compounds.

nclosed to capture process emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) are released during shredding, including small amounts of halogenated compounds.

(TO) that treats a rich stream of chlorinated compounds and an organic silicon compound. HCl and silicon dioxide (SiO2) particulate are formed during combustion. The exhaust is treated by a Hastelloy evaporative quencher followed by a caustic scrubber.

(TO) that treats a rich stream of chlorinated compounds and an organic silicon compound. HCl and silicon dioxide (SiO2) particulate are formed during combustion. The exhaust is treated by a Hastelloy evaporative quencher followed by a caustic scrubber.

into a consistent granular media. The media is used as a natural microbial carrier to inoculate millions of acres of food crops each year. The transformation process relies on drying harvested material in industrial rotary dryers. A fraction of the material becomes entrained in the flue gas as particulate emissions. The facility is expanding operations to double the capacity. A scrubber solution is needed to reduce total plant particulate emissions.

into a consistent granular media. The media is used as a natural microbial carrier to inoculate millions of acres of food crops each year. The transformation process relies on drying harvested material in industrial rotary dryers. A fraction of the material becomes entrained in the flue gas as particulate emissions. The facility is expanding operations to double the capacity. A scrubber solution is needed to reduce total plant particulate emissions. ers. The scrubbers are comprised of a variable throat Venturi scrubber and a chevron style entrainment separator mounted on an equipment skid. The scope of supply for each scrubber includes a control system, re-circulation pump with pre-assembled piping, valves and fittings. Instruments are pre-mounted in the piping where possible and pre-wired to a junction box on the skid. The horizontal configuration provides a compact design to fit inside the building with easy maintenance access to valves and instruments.

ers. The scrubbers are comprised of a variable throat Venturi scrubber and a chevron style entrainment separator mounted on an equipment skid. The scope of supply for each scrubber includes a control system, re-circulation pump with pre-assembled piping, valves and fittings. Instruments are pre-mounted in the piping where possible and pre-wired to a junction box on the skid. The horizontal configuration provides a compact design to fit inside the building with easy maintenance access to valves and instruments.

needed to remove particulate from a chlorine gas stream that originates in the anode compartments of electrolytic cells that produce magnesium metal. A significant portion of the particulate is less than 1 micron in size, making it difficult to remove.

needed to remove particulate from a chlorine gas stream that originates in the anode compartments of electrolytic cells that produce magnesium metal. A significant portion of the particulate is less than 1 micron in size, making it difficult to remove. tic (FRP) Venturi scrubber and horizontal chevron style entrainment separator. Additional scope of supply includes instruments, pre-assembled pump skid with redundant titanium pumps (1 operating and 1 spare), pre-assembled CPVC piping, redundant fans with titanium wheel and housing, interconnect FRP ductwork, dampers, and equipment skid and platforms.

tic (FRP) Venturi scrubber and horizontal chevron style entrainment separator. Additional scope of supply includes instruments, pre-assembled pump skid with redundant titanium pumps (1 operating and 1 spare), pre-assembled CPVC piping, redundant fans with titanium wheel and housing, interconnect FRP ductwork, dampers, and equipment skid and platforms.

The thermal oxidizers need a wet scrubber to neutralize and remove SO2. Flue gas entering the scrubber contain some sulfur trioxide (SO3) which is converted to sulfuric acid (H2SO4) in the quencher. Sulfuric acid is a submicron liquid aerosol that passes through the downstream packed bed absorber. Some facilities are now being regulated for H2SO4. This paper evaluates and compares candle filters versus wet electrostatic precipitators (WESP’s) for H2SO4 removal in these applications.

The thermal oxidizers need a wet scrubber to neutralize and remove SO2. Flue gas entering the scrubber contain some sulfur trioxide (SO3) which is converted to sulfuric acid (H2SO4) in the quencher. Sulfuric acid is a submicron liquid aerosol that passes through the downstream packed bed absorber. Some facilities are now being regulated for H2SO4. This paper evaluates and compares candle filters versus wet electrostatic precipitators (WESP’s) for H2SO4 removal in these applications. Waste water treatment facilities operating sewage sludge incinerators (SSI) can reduce sludge volume and disposal costs by combusting dewatered sewage sludge. Emissions are regulated by the US EPA Maximum Available Control Technology (MACT) standard 40 CFR Part 60 and 62 to control particulate, lead (Pb), cadmium (Cd), SO2, HCl, dioxins/furans, and mercury (Hg). Many SSI’s need a control device specifically for mercury. This paper evaluates two mercury control technologies: sulfur‐impregnated activated carbon and Gore sorbent polymer catalyst (SPC) modules. Several facilities have used sulfur-impregnated activated carbon but safety issues have arisen due to fires which have shut down some systems. The Gore SPC modules are a relatively new technology with at least seven installations. A comparison is made of capital cost, operating cost, mercury removal efficiency, fire and performance risks based on incineration of 3,000 lbs/hr of sewage sludge. Finally, an overview is provided for an Envitech SPC mercury control scrubber operating at one facility.

Waste water treatment facilities operating sewage sludge incinerators (SSI) can reduce sludge volume and disposal costs by combusting dewatered sewage sludge. Emissions are regulated by the US EPA Maximum Available Control Technology (MACT) standard 40 CFR Part 60 and 62 to control particulate, lead (Pb), cadmium (Cd), SO2, HCl, dioxins/furans, and mercury (Hg). Many SSI’s need a control device specifically for mercury. This paper evaluates two mercury control technologies: sulfur‐impregnated activated carbon and Gore sorbent polymer catalyst (SPC) modules. Several facilities have used sulfur-impregnated activated carbon but safety issues have arisen due to fires which have shut down some systems. The Gore SPC modules are a relatively new technology with at least seven installations. A comparison is made of capital cost, operating cost, mercury removal efficiency, fire and performance risks based on incineration of 3,000 lbs/hr of sewage sludge. Finally, an overview is provided for an Envitech SPC mercury control scrubber operating at one facility.