Hot mix asphalt (HMA) plants combine aggregate and petroleum byproducts to form paving material. HMA plants can be permanent, transportable (skid-mounted), or portable. For large asphalt projects, it is economical to use transportable or portable HMA plants so as to set up near the project and reduce the delivery time of asphalt to the site. Large HMA manufacturers thus transport their manufacturing equipment from site to site.

The most common HMA plant is a batch mix plant. A batch plant consists of an aggregate dryer to dewater the aggregate, a mixer to combine the aggregate with asphalt cement, and a load-out bay for transferring the final product to trucks for transport. Auxiliary equipment includes a cyclone for aggregate collection after the dryer, a secondary collection device for particulate emissions, a blue haze control device to curb VOC emissions. Reclaimed asphalt pavement (RAP) is typically used to reduce costs and promote sustainability within the industry. The stage at which RAP is introduced depends on the qualities of the RAP and the desired properties of the final asphalt product.

According to the EPA, there are two primary techologies for the secondary collection devices: Venturi scrubbers and baghouses. Venturi scrubbers are wet devices that capture particulate through inertial impaction. Venturis are fractional efficiency devices capable of efficiently capturing particulate as small as 1 micron. Venturis are inherently self cleaning: water sprays continuously from the Venturi throat and the accelerated gas shears any wall buildup. Thus, Venturis are excellent in the removal of sticky particulate that would foul other forms of particulate control. Also, as a wet process, Venturis have the ability of capturing condensables and water soluble vapors. The alternative technology for secondary particulate capture is a baghouse. A baghouse achieves particle collection by filtering the gas through a physical barrier. Baghouses can efficiently remove submicron particulate, provided that the particulate is filterable. Baghouses are not able to capture condensibles, but can capture some acid gases if an appropriate dry chemical is added to the dryer flue gas.

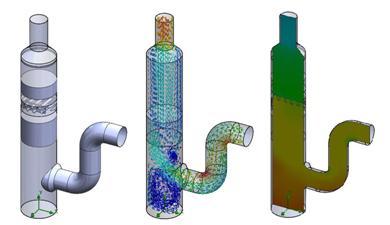

Recently, Envitech has developed an economical Venturi scrubber that can be either built on a skid for easy transport, or built on a truck bed for portability. Envitech's Venturi scrubber is capable of meeting even the most stringent PM-10 requirements for particulate control, and works well with downstream blue haze control devices. Our Venturi scrubber is also anti-fouling and capable of consistently meeting control targets even with difficult RAP and exotic formulations with minimal maintenance.

Ethylene amines are one of the major chemical building blocks. Ethylene amines include ethylenediamine (EDA), diethylenetriamine (DETA), triethyltriamine (TETA) as well as other longer chained ethylene amines. Amongst its many uses, ethylene amine is one of the two principal chemical ingredients in making ethylenediaminetetracetic acid (EDTA), the most common chelating agent in the world. Diamines are also used in the manufacture of the ubiquitious textile Nylon. Due to its excellent properties, it is also used extensively in the asphalt, petrochemical, rubber, pesticide, and paper industries.

Ethylene amines are one of the major chemical building blocks. Ethylene amines include ethylenediamine (EDA), diethylenetriamine (DETA), triethyltriamine (TETA) as well as other longer chained ethylene amines. Amongst its many uses, ethylene amine is one of the two principal chemical ingredients in making ethylenediaminetetracetic acid (EDTA), the most common chelating agent in the world. Diamines are also used in the manufacture of the ubiquitious textile Nylon. Due to its excellent properties, it is also used extensively in the asphalt, petrochemical, rubber, pesticide, and paper industries.

Compliance testing often brings anxiety to environmental managers. Testing is expensive and can comprise a significant fraction of the environmental operating budget. Planning takes several months, often culminating in a tight testing window with long days and unforeseen delays. And always looming is a dreaded phone call of a failed test. What three things should environmental managers do to ensure a successful compliance test?

Compliance testing often brings anxiety to environmental managers. Testing is expensive and can comprise a significant fraction of the environmental operating budget. Planning takes several months, often culminating in a tight testing window with long days and unforeseen delays. And always looming is a dreaded phone call of a failed test. What three things should environmental managers do to ensure a successful compliance test?

Envitech is proud to launch a new scrubber service and maintenance program for all users of air pollution control equipment. Envitech offers the program to provide plant managers, environmental departments, plant engineering and operations and maintenance staffs access to our trained, experienced group of engineers and technicians. Our goal is to improve your uptime, reduce your operating costs, ensure you meet compliance and offer you an on-demand technical resource for troubleshooting your equipment. Additionally, we want to help you organize your maintenance programs and provide training to keep your operators up to date.

Envitech is proud to launch a new scrubber service and maintenance program for all users of air pollution control equipment. Envitech offers the program to provide plant managers, environmental departments, plant engineering and operations and maintenance staffs access to our trained, experienced group of engineers and technicians. Our goal is to improve your uptime, reduce your operating costs, ensure you meet compliance and offer you an on-demand technical resource for troubleshooting your equipment. Additionally, we want to help you organize your maintenance programs and provide training to keep your operators up to date.

architecture and marine engineering firm. The panel was comprised of potential marine exhaust gas scrubber vendors. The intent of the workshop was to provide information to cruise line participants to assess the maturity of the industry and the likelihood that exhaust gas cleaning systems will be a feasible response to the challenges of changes in regulations.

architecture and marine engineering firm. The panel was comprised of potential marine exhaust gas scrubber vendors. The intent of the workshop was to provide information to cruise line participants to assess the maturity of the industry and the likelihood that exhaust gas cleaning systems will be a feasible response to the challenges of changes in regulations.