A common application for Venturi scrubbers is potash mining. Venturi scrubbers are used to remove particulate from industrial dryers that dry the potash material. A cyclonic separator or chevron style entrainment separatordownstream of the Venturi removes particulate–laden water droplets from the gas before it is exhausted into the atmosphere. The type of entrainment separator can impact the system performance and make a significant difference in plant emissions. A well designed chevron style mist eliminator achieves significantly lower emissions than a cyclonic separator. This is because the chevron style mist eliminator allows the Venturi scrubber to operated at a higher pressure drop for the same system pressure drop. The chevron entrainment separator is also more efficient at removing water drops.

difference in plant emissions. A well designed chevron style mist eliminator achieves significantly lower emissions than a cyclonic separator. This is because the chevron style mist eliminator allows the Venturi scrubber to operated at a higher pressure drop for the same system pressure drop. The chevron entrainment separator is also more efficient at removing water drops.

A chevron style mist eliminator removes more than 99% of the water droplets down to 25 microns with less than 0.25 inches W.C. of pressure drop. By comparison, a cyclonic mist eliminator requires 4 to 6 inches W.C. of pressure drop to remove 98% of 25 micron droplets. The additional pressure drop required by the cyclonic separator effectively reduces the pressure drop that can be applied to the Venturi throat and consequently lowers collection efficiency. The additional water droplets that escape the cyclonic separator (98% vs. 99% removal for 25 micron water droplets) contain particulate which will impact stack test results.

Consider an air permit for a potash facility located in the Southwestern United States. The permit allows for the operation of two 2 dryer systems, each with a Venturi scrubber. The dryers contribute significantly to the facility wide total suspended particulate (TSP) emissions. A typical potash dryer for this size of facility exhausts around 40,000 acfm with a particulate loading as high as 3 gr/dscf. This is a little more than half a ton per hour of particulate for both dryers.

Venturi scrubbers with cyclonic separators designed for 99% removal result in approximately 10.4 lb/hr of particulate emissions for both scrubbers or 46 tpy. However, an equivalent Venturi scrubber with a chevron style mist eliminator achieves 99.9% removal. This results in less than 1 lb/hr of particulate emissions for both dryers, or less than 5 tpy. The higher performing Venturi scrubber design reduces plant emissions by over 40 tpy. This performance increase can have a significant difference in air quality for the surrounding community.

To download a case study on dryer Venturi scrubber, please click on the download button below.

I gave recent presentations at the International Thermal Treatment (IT3) Conference in San Francisco and the Annual

I gave recent presentations at the International Thermal Treatment (IT3) Conference in San Francisco and the Annual

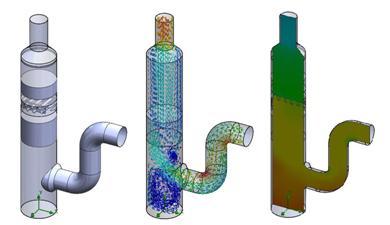

house gases. One aspect of this technology is the use of coal dryers to dry the coal before feeding it into the gasifier. This requires a coal dryer scrubber which can be comprised of a Venturi scrubber followed by a condenser tower shown in the sketch.

house gases. One aspect of this technology is the use of coal dryers to dry the coal before feeding it into the gasifier. This requires a coal dryer scrubber which can be comprised of a Venturi scrubber followed by a condenser tower shown in the sketch. tower. Gas flow rates for these processes are relatively large and can exceed 300,000 acfm. Because of the large gas flows, the condenser tower can be as large as 20 feet in diameter or larger. The Venturi scrubber (shown in the image on the left) must have a special throat design to account for the large gas flow rate. The Venturi throat design is discussed in in the previous blog post for

tower. Gas flow rates for these processes are relatively large and can exceed 300,000 acfm. Because of the large gas flows, the condenser tower can be as large as 20 feet in diameter or larger. The Venturi scrubber (shown in the image on the left) must have a special throat design to account for the large gas flow rate. The Venturi throat design is discussed in in the previous blog post for

The adjacent photo shows a 400 lb/hr medical waste incinerator scrubber with a Venturi inlet flow rate of 1,200 scfm. The reflux damper can be seen as the white horizontal duct from the ID fan outlet to the Venturi inlet on the right hand side of the rectangular condenser/absorber box.

The adjacent photo shows a 400 lb/hr medical waste incinerator scrubber with a Venturi inlet flow rate of 1,200 scfm. The reflux damper can be seen as the white horizontal duct from the ID fan outlet to the Venturi inlet on the right hand side of the rectangular condenser/absorber box.

Removal of the bulk particulate load - Removal of the bulk particulate load may be required if there is a high particulate concentration from the upstream process. This will be the case for secondary lead smelters, lead refining, and refinery sludge incinerators. Geothermal energy plants will not have this requirement. A bag-house will be used for secondary lead smelters and lead refining. A wet Venturi scrubber system can be used for refinery sludge incinerators Removal of the bulk particulate minimizes space-charge effects inside the WESP. Space-charge effects occur when particles interact and repel each other. This reduces WESP performance because it interferes with the migration of charged particle to the tube wall for collection.

Removal of the bulk particulate load - Removal of the bulk particulate load may be required if there is a high particulate concentration from the upstream process. This will be the case for secondary lead smelters, lead refining, and refinery sludge incinerators. Geothermal energy plants will not have this requirement. A bag-house will be used for secondary lead smelters and lead refining. A wet Venturi scrubber system can be used for refinery sludge incinerators Removal of the bulk particulate minimizes space-charge effects inside the WESP. Space-charge effects occur when particles interact and repel each other. This reduces WESP performance because it interferes with the migration of charged particle to the tube wall for collection.

owing pollutants.

owing pollutants. control to meet the more stringent standards. Envitech has had success achieving higher removal efficiencies by integrating an add-on particulate polishing package (PPP) into incinerator wet scrubber systems. The PPP is comprised of a skid mounted package that provides slight reheat of the gas temperature to slightly above saturation in combination with a filter system. The reheat eliminates the potential for condensation build-up in the filters.

control to meet the more stringent standards. Envitech has had success achieving higher removal efficiencies by integrating an add-on particulate polishing package (PPP) into incinerator wet scrubber systems. The PPP is comprised of a skid mounted package that provides slight reheat of the gas temperature to slightly above saturation in combination with a filter system. The reheat eliminates the potential for condensation build-up in the filters.

Venturi scrubber

Venturi scrubber