The University of California, Davis (UCD) operates an anaerobic biodigester that converts 50 metric tons of  food waste per day into 100 MMBtu/d of renewable energy biogas. The digester is sited near campus at a decommissioned landfill.

food waste per day into 100 MMBtu/d of renewable energy biogas. The digester is sited near campus at a decommissioned landfill.

The biodigester produces a digestate liquid waste stream. It’s odor and high ammonia concentration render it unsuitable for composting or direct land-applied fertilizer. To avoid expensive hauling costs, a distillation column strips ammonia out of the digestate into the vapor phase so that the digestate can be treated in an existing Wastewater Treatment Plant (WWTP). An Ammonia Scrubber Package is needed to meet air emission limits and to recover a saleable liquid fertilizer product from the vapor phase ammonia.

Ammonia is an odorless gas that is harmful to human health with a permissible exposure limit (PEL) of 50 ppm. The scrubber must have high removal efficiency and be capable of treating a low flow rate exhaust and be robust and reliable.

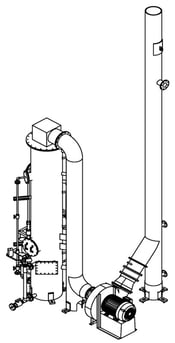

The customer selected an Envitech ammonia lab scrubber. The scope of supply includes a fiber reinforced plastic (FRP) packed bed absorber, instruments pre-wired to a control system w ith HMI, pre-assembled pump, piping, valves and fittings, ID fan with VFD, and free-standing interconnect duct and stack.

ith HMI, pre-assembled pump, piping, valves and fittings, ID fan with VFD, and free-standing interconnect duct and stack.

Ammonia laden stripped gas enters the scrubber and travels vertically upward through the packed bed, counter-current to downward flowing recirculation liquid. Scrubbing liquid is collected in the sump and is re-circulated to the top of the packed bed. Sulfuric acid (H2SO4) is metered into the recirculation line to neutralize ammonia and is controlled by pH. A blowdown stream purges ammonia sulfate (NH4)2SO4 reaction products which can be sold as fertilizer. A mist eliminator at the top of the scrubber removes entrained water droplets before exiting through an induced draft fan and stack.

The ammonia scrubber will be commissioned in the 1st half of 2020 and will meet the design parameters and performances below.

DESIGN PARAMETER

- Inlet flow rate: 1,000 acfm (capable of up to 2,000 acfm)

- Inlet temperature: 160oF

- Gas Composition: Air with 1.4% mole ammonia

- Ammonia Removal: > 97.5% permitted (capable of > 99% removal).

Click on the link below to download a case study and other packed bed scrubbing literature.