As the EPA continues to tighten the emissions belt, I am seeing new industries with air emissions issues. One such industry is pharmaceuticals, who are now more commonly regulated for acid gases on post-combustion devices.

As the EPA continues to tighten the emissions belt, I am seeing new industries with air emissions issues. One such industry is pharmaceuticals, who are now more commonly regulated for acid gases on post-combustion devices.

Pharmaceutical air emissions are typically a result of an organic fume from a solvent. The fume, containing vaporized solvent, is captured either within a fume hood or central ventilation system. When regulated, the most effective way of removing a fume is to combust it in a regenerative thermal oxidizer (RTO) or some other combustion device.

The combustion of a solvent such as methyl chloride in an RTO leaves three compounds: carbon dioxide, water vapor, and hydrochloric acid. The last of the three - hydrochloric acid - is often treated as an emission and if so must be removed from the outlet exhaust.

Pharmaceutical Scrubber

The most best method for removing hydrochloric acid from a gas is the use of a pharmaceutical scrubber. A scrubber offers extremely high efficiencies (greater than 99%, or as required) at a low pressure drop. Recirculating neutralized water across a packed tower, the capital and operating cost of a scrubber is minimal. Further, the effluent from a HCl scrubber contains only sodium chloride - table salt - and can easily be disposed of through a wastewater sewer with little to no further treatment. Using FRP for the scrubber provides a low cost building material highly resistant to acid attack.

Hydrochloric Acid Corrosion

The removal of hydrochloric acid from a combustion exhaust does offer one particular difficulty over other common acid gases, of which designers and operators in the pharmaceutical industry need to be wary. Hydrochloric acid and neutralized chlorides are very aggressive towards most metals, especially so at elevated temperatures typically seen on the outlet of a combustion process. Since the HCl is contained in the exhaust of a combustion process, the inlet gas temperature to the scrubber is high. In turn, the recirculation water temperature is also high, usually well above 100F. Standard metallic materials such as stainless steel will quickly corrode in this environment.

In the past, I have used both AL6XN and hastelloy for metallic materials in HCl scrubber systems. Common metallic items in a pharmaceutical scrubber include the quencher, instrumentation, and downstream devices. AL6XN is a duplex material that provides very good corrosion resistance to around 1000F. It also has about an order of magnitude greater chloride pitting resistance than stainless steel at neutral pH, and over two magnitudes resistance at low pH. AL6XN is ideal for quenchers on the exhaust of an RTO, where the outlet temperature is usually around 500F. Hastelloy is more expensive, but it offers heat resistance to 2500F as well as a further order of magnitude resistance to chlorides over AL6XN.

Hydrochloric Acid Mist

The other issue provided by hydrochloric acid in a gas stream is the formation of hydrochloric acid mist, which I have previously touched upon in my acid gas dewpoint post.

Hydrochloric acid mist usually requires a high efficiency mesh pad for removal of any HCl aerosols that may form in the scrubber. A mesh pad is more expensive than a standard wave form mist eliminator, and is also much more prone to particulate plugging. If hydrochloric acid is in your gas stream, make sure you consider a mesh pad and beware of particulate!

If you would like to learn more about corrosive acid gas scrubbers, download the free case study below.

Venturi scrubber

Venturi scrubber

Acid gases can be found in the exhaust of a large number of combustion processes. As a gas, the acid compounds usually are not particularly corrosive and are relatively easy to remove. However, when the temperature of the gas drops below the acid gas dewpoint, an acid mist can form. The acid mist can turn into a fine aerosol or it can condense on a cold surface. Acid mist poses a number of design problems, due to the small size of the mist particles and the corrosivity of the liquid form of the acid.

Acid gases can be found in the exhaust of a large number of combustion processes. As a gas, the acid compounds usually are not particularly corrosive and are relatively easy to remove. However, when the temperature of the gas drops below the acid gas dewpoint, an acid mist can form. The acid mist can turn into a fine aerosol or it can condense on a cold surface. Acid mist poses a number of design problems, due to the small size of the mist particles and the corrosivity of the liquid form of the acid.

One of the most difficult value engineering challenges I encounter is the selection of instrumentation. Instrumentation within air pollution control systems may be subject to high salinity, high halide concentrations, pH swings, extreme temperatures, extreme ambient conditions, intrinsically safe environments, and abrasive particulate, just to name a few. Selecting the proper instrumentation for each environment is a chore and can dramatically effect the cost. It is a topic that both end-users and integrators should attempt to resolve before a system is built.

One of the most difficult value engineering challenges I encounter is the selection of instrumentation. Instrumentation within air pollution control systems may be subject to high salinity, high halide concentrations, pH swings, extreme temperatures, extreme ambient conditions, intrinsically safe environments, and abrasive particulate, just to name a few. Selecting the proper instrumentation for each environment is a chore and can dramatically effect the cost. It is a topic that both end-users and integrators should attempt to resolve before a system is built. The primary products of synthetic gas (syngas) production from biomass are hydrogen gas, carbon monoxide, and methane. Unfortunately, those are not the only compounds formed. Other compounds form depending on the elemental chemistry of the biomass. One of the more common byproducts is ammonia, released from organically-bound nitrogen.

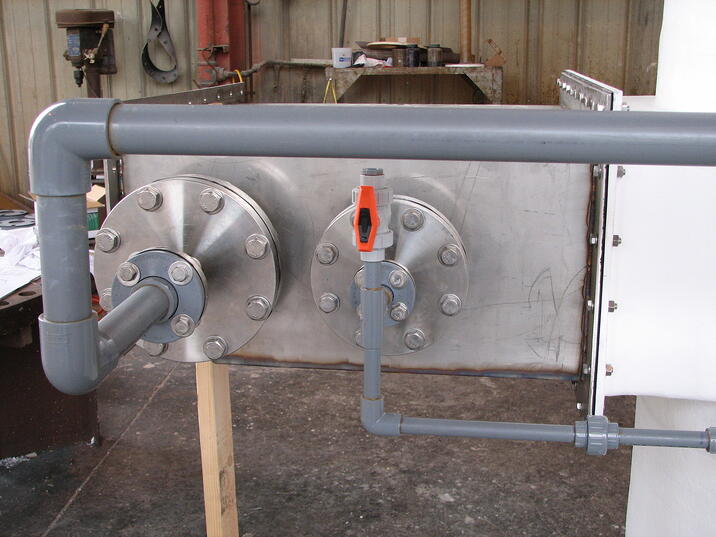

The primary products of synthetic gas (syngas) production from biomass are hydrogen gas, carbon monoxide, and methane. Unfortunately, those are not the only compounds formed. Other compounds form depending on the elemental chemistry of the biomass. One of the more common byproducts is ammonia, released from organically-bound nitrogen. In the picture to the right, the spray headers are installed using a double flange approach. The two flange approach improves the accessibility of the nozzles in the quencher, which can be susceptible to plugging in some applications. Water is connected to the first (header) flange. The second flange connects to the quencher. The spray header can then be removed like a lance.

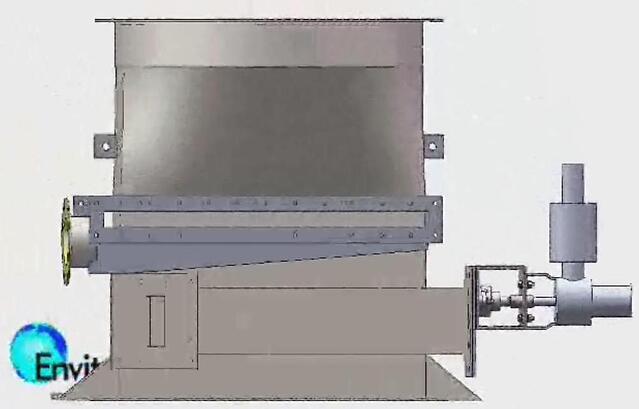

In the picture to the right, the spray headers are installed using a double flange approach. The two flange approach improves the accessibility of the nozzles in the quencher, which can be susceptible to plugging in some applications. Water is connected to the first (header) flange. The second flange connects to the quencher. The spray header can then be removed like a lance. The picture to the left shows an example of a rectangular quencher. A rectangular quencher in low flow, low temperature quench applications are typically more cost-effective than round quenchers, especially if they are attaching to rectangular or horizontal ducts.

The picture to the left shows an example of a rectangular quencher. A rectangular quencher in low flow, low temperature quench applications are typically more cost-effective than round quenchers, especially if they are attaching to rectangular or horizontal ducts.

Biomass Production

Biomass Production