A major pharmaceutical company is implementing an expansion project in their Midwest facility. It includes two production Fermentors, a secondary feed tank and secondary make-up tank. Combined vent gases contain up to 1,500 ppmv (24 lb/hr) of Hydrogen Sulfide (H2S) in air.

a secondary feed tank and secondary make-up tank. Combined vent gases contain up to 1,500 ppmv (24 lb/hr) of Hydrogen Sulfide (H2S) in air.

H2S is a highly toxic gas that can kill or seriously harm human health when exposed to it. For general industry the OSHA permissible exposure limit (PEL) is 20 ppm for an 8 hour period. The specification requires 99.9% removal which achieves less than 1.5 ppmv, well below the PEL.

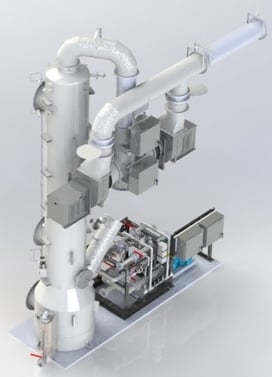

Installation is on the first floor with a limited footprint area of 18 ft L x 8 ft W. Redundancy is required for pumps and ID fans. The customer desires maximum integration and pre-assembly to limit installation work on site.

The customer selected an Envitech H2S packed bed scrubber. The scope includes a fiber reinforced plastic (FRP) packed bed absorber, instruments, recirculation pumps (1 operating, 1 spare), pre-assembled CPVC piping, valves, and fittings with pre-mounted instruments, metering pumps, ID fans (1 operating, 1 spare), interconnect duct, and stack.

The stack passes through a second floor before breeching the roof. Fans are located near the outlet on a mezzanine. A custom arrangement accounts for obstacles and interferences in the installation space.

Vent gases enter the bottom of the absorber and travels vertically upward. A removable spray nozzle in the quench zone pre-scrubs and cools the process vent stream. Recirculated water sprayed over the packed bed mixes with counter current upward flowing gas. A dilute solution of sodium hydroxide (NaOH) and sodium hypochlorite (NaOCl) metered into the recirculation line neutralizes and oxidizes acid gases. Chemical addition is controlled by pH and ORP.

Vent gases enter the bottom of the absorber and travels vertically upward. A removable spray nozzle in the quench zone pre-scrubs and cools the process vent stream. Recirculated water sprayed over the packed bed mixes with counter current upward flowing gas. A dilute solution of sodium hydroxide (NaOH) and sodium hypochlorite (NaOCl) metered into the recirculation line neutralizes and oxidizes acid gases. Chemical addition is controlled by pH and ORP.

An entrainment separator at the top of the absorber removes water droplets before exiting the scrubber.

The equipment has been delivered and will be installed in early 2020. Design and performance parameters are summarized below.

DESIGN PARAMETER

- Inlet flow rate: 3,000 acfm

- Inlet temperature: 102oF to 212oF

- H2S inlet concentration: 1,500 ppmv

- H2S Removal: > 99.9%

Click on the link below to download a case study and other packed bed scrubbing literature.