One of the most difficult value engineering challenges I encounter is the selection of instrumentation. Instrumentation within air pollution control systems may be subject to high salinity, high halide concentrations, pH swings, extreme temperatures, extreme ambient conditions, intrinsically safe environments, and abrasive particulate, just to name a few. Selecting the proper instrumentation for each environment is a chore and can dramatically effect the cost. It is a topic that both end-users and integrators should attempt to resolve before a system is built.

One of the most difficult value engineering challenges I encounter is the selection of instrumentation. Instrumentation within air pollution control systems may be subject to high salinity, high halide concentrations, pH swings, extreme temperatures, extreme ambient conditions, intrinsically safe environments, and abrasive particulate, just to name a few. Selecting the proper instrumentation for each environment is a chore and can dramatically effect the cost. It is a topic that both end-users and integrators should attempt to resolve before a system is built.

Extreme temperatures

Most know of the obvious differences between outside environments as opposed to inside environments. Rain, snow, and sun all batter instruments outside; equipment inside rarely see any of the three. Extreme heat though is not the exclusive domain of outside environments - I am currently working on a project where inside temperatures can reach 140F. For that project, I have moved all of the temperature sensitive transmitters inside an air conditioned control cabinet to meet the temperature requirements of the analyzer. When dealing with extreme temperatures, it is best to find ways to reduce the effect. For extreme cold environments, use insulation or heat tracing. For the extreme heat, look at moving sensitive electrical equipment into a temperature controlled environment. Remember, plan for the extremes!

Be a copycat

A lot of the projects that I see are retrofits - the addition of new air pollution control equipment on existing processes or equipment. In these cases, it is usually best to select instrumentation that is already working well within the plant. First, copying instrumentation removes most doubts of instrument failures. Second, operators have a familiarity with the instrumentation, and are more apt to use the instrumentation properly. Finally, copying instrumentation reduces the number of spares that a plant needs to keep available, thus reducing the net cost of the instrument. Whether you are buying the equipment for a customer, or buying equipment with prepackaged instrumentation, always find out what instrumentation is already working!

Preventive Maintenance

Even after selecting the right equipment, there is still the need to properly maintain the equipment. Acid gas scrubbers almost always require a pH probe for dosing basic reagents; those pH probes require regular calibration and often have lifetimes of six months. A probe off by 1.5 pH units can cause a drop in acid gas removal efficiency from 99% to 75% - a significant problem if your stack tester is visiting! Conductivity sensors and hardness analyzer and ion selective electrodes also require regular maintenance.

For instruments that do require calibration, it is important to use bypasses to allow for calibration during operation. A bypass loop with an instrument hold function allows an operator to carefully calibrate the instrument while the system continues to operate in a safe fashion.

Recommendations

Above all else, work with the end-user to identify instrumentation requirements. A customer running a 24/7 operation has dramatically different requirements for instrumentation than one that is on a single shift operation or batch process. Operators should be thought of as well. Are the instruments accessible? Can operators view indicators?

Remember, selecting the right instrumentation minimizes downtime; downtime that may cost you ten times the price of the instrument.

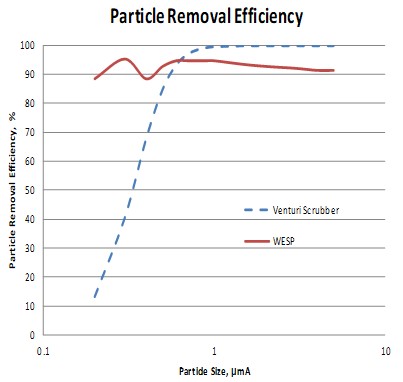

Envitech is often asked to make recommendations for particulate removal on a wide range of industrial applications. This might entail deciding if a

Envitech is often asked to make recommendations for particulate removal on a wide range of industrial applications. This might entail deciding if a  There are several test methods for determining the particle size distribution, however the test method must determine the aerodynamic particle size to adequately predict the Venturi performance. The most common method for determining the aerodynamic particle size is to use a cascade impactor. This can be a challenging test because the inlet gas stream may be at high temperature and contain a high particulate loading and moisture content. It is important to select a testing company that has experience with this type of environment. Below is a references from the

There are several test methods for determining the particle size distribution, however the test method must determine the aerodynamic particle size to adequately predict the Venturi performance. The most common method for determining the aerodynamic particle size is to use a cascade impactor. This can be a challenging test because the inlet gas stream may be at high temperature and contain a high particulate loading and moisture content. It is important to select a testing company that has experience with this type of environment. Below is a references from the

The primary products of synthetic gas (syngas) production from biomass are hydrogen gas, carbon monoxide, and methane. Unfortunately, those are not the only compounds formed. Other compounds form depending on the elemental chemistry of the biomass. One of the more common byproducts is ammonia, released from organically-bound nitrogen.

The primary products of synthetic gas (syngas) production from biomass are hydrogen gas, carbon monoxide, and methane. Unfortunately, those are not the only compounds formed. Other compounds form depending on the elemental chemistry of the biomass. One of the more common byproducts is ammonia, released from organically-bound nitrogen.

In the picture to the right, the spray headers are installed using a double flange approach. The two flange approach improves the accessibility of the nozzles in the quencher, which can be susceptible to plugging in some applications. Water is connected to the first (header) flange. The second flange connects to the quencher. The spray header can then be removed like a lance.

In the picture to the right, the spray headers are installed using a double flange approach. The two flange approach improves the accessibility of the nozzles in the quencher, which can be susceptible to plugging in some applications. Water is connected to the first (header) flange. The second flange connects to the quencher. The spray header can then be removed like a lance. The picture to the left shows an example of a rectangular quencher. A rectangular quencher in low flow, low temperature quench applications are typically more cost-effective than round quenchers, especially if they are attaching to rectangular or horizontal ducts.

The picture to the left shows an example of a rectangular quencher. A rectangular quencher in low flow, low temperature quench applications are typically more cost-effective than round quenchers, especially if they are attaching to rectangular or horizontal ducts.

Biomass Production

Biomass Production