HCl emissions are encountered in a wide range of applications including hazardous waste combustors (HWC), medical waste incinerators, pharmaceutical production, and ceramic tile manufacturing. There is a wide range of performance requirements depending on the application and applicable state or US EPA standard. Below is a summary of performance requirements for some of these applications.

HCl emissions are encountered in a wide range of applications including hazardous waste combustors (HWC), medical waste incinerators, pharmaceutical production, and ceramic tile manufacturing. There is a wide range of performance requirements depending on the application and applicable state or US EPA standard. Below is a summary of performance requirements for some of these applications.

- Hospital, medical, and infectious waste incinerator (HMIWI) MACT standard: 5.1 to 15 ppmv depending on the size of the incinerator and whether it is an existing or new incinerator.

- Hazardous waste combustor (HWC) MACT standard: 32 ppmv for existing incinerators and 21 ppmv for new incinerators; adjusted to 7% O2.

- Ceramic tile kiln scrubber: > 97% removal

- Pharmaceutical manufacturing RTO scrubber: > 99% removal

It is well known that gaseous HCl readily absorbs into water and can be removed with high efficiency with caustic addition. The challenge however is that a fraction of the inlet HCl condenses into acid aerosol when hot gas from the thermal oxidizer contacts water in the quencher. The aerosol quantity formed and the particle size distribution (PSD) of the acid droplets vary from process to process. Predictive models to accurately estimate these values are limited and imprecise. In some cases as much as 20% of the HCl can form an acid aerosol fog. Aerosol carry-over exhausting from the scrubber will show up in stack tests and contribute to plant emissions.

It is well known that gaseous HCl readily absorbs into water and can be removed with high efficiency with caustic addition. The challenge however is that a fraction of the inlet HCl condenses into acid aerosol when hot gas from the thermal oxidizer contacts water in the quencher. The aerosol quantity formed and the particle size distribution (PSD) of the acid droplets vary from process to process. Predictive models to accurately estimate these values are limited and imprecise. In some cases as much as 20% of the HCl can form an acid aerosol fog. Aerosol carry-over exhausting from the scrubber will show up in stack tests and contribute to plant emissions.

It is common for HCl scrubbers to utilize mesh pads above the packed bed to remove aerosol droplets before exiting the scrubber. As noted above, many applications require 97% to 99% removal efficiency. This arrangement is generally adequate for these removal efficiencies. The proposed NESHAP standards for vinyl chloride facilities, however, requires higher efficiency. This increased efficiency demand requires additional consideration in the scrubber design and mist eliminator to guarantee performance. Facilities should rely on experienced scrubber suppliers that understand HCl aerosol and account for it in the scrubber design to guarantee emission limits.

Click on the link below to download HCl scrubber literature.

removed after the RTO.

removed after the RTO.

Vintage Petroleum, LLC, a subsidiary of Occidental Petroleum Corporation operates oil and gas fields in Lost Hills, California, northwest of Bakersfield. The fields operate steam boilers that use nearby canal water. High concentrations of dissolved oxygen in the canal water caused excessive corrosion in the boilers.

Vintage Petroleum, LLC, a subsidiary of Occidental Petroleum Corporation operates oil and gas fields in Lost Hills, California, northwest of Bakersfield. The fields operate steam boilers that use nearby canal water. High concentrations of dissolved oxygen in the canal water caused excessive corrosion in the boilers.

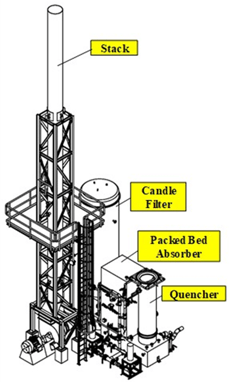

nclosed to capture process emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) are released during shredding, including small amounts of halogenated compounds.

nclosed to capture process emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) are released during shredding, including small amounts of halogenated compounds.

(TO) that treats a rich stream of chlorinated compounds and an organic silicon compound. HCl and silicon dioxide (SiO2) particulate are formed during combustion. The exhaust is treated by a Hastelloy evaporative quencher followed by a caustic scrubber.

(TO) that treats a rich stream of chlorinated compounds and an organic silicon compound. HCl and silicon dioxide (SiO2) particulate are formed during combustion. The exhaust is treated by a Hastelloy evaporative quencher followed by a caustic scrubber.

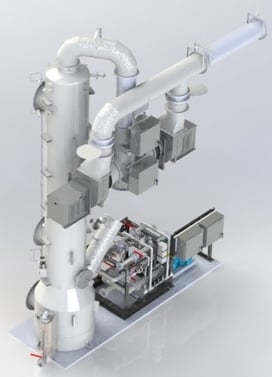

Waste oil is recycled and refined into low sulfur marine diesel and other industrial fuels at West Coast refineries. Waste gas is sent to thermal oxidizers for volatile organic compound (VOC) destruction. Sulfur compounds in the waste gas are oxidized to SO2 and removed by a packed bed scrubber. A fraction of SO2 converts to sulfur trioxide (SO3) before entering the scrubber. SO3 further converts to sulfuric acid (H2SO4) and generates a submicron liquid mist upon quenching the gas. New ground level pollutant regulations require removal of sulfuric acid mist before exhausting the flue gas to atmosphere. A multi-pollutant solution is needed to remove both SO2 and sulfuric acid mist.

Waste oil is recycled and refined into low sulfur marine diesel and other industrial fuels at West Coast refineries. Waste gas is sent to thermal oxidizers for volatile organic compound (VOC) destruction. Sulfur compounds in the waste gas are oxidized to SO2 and removed by a packed bed scrubber. A fraction of SO2 converts to sulfur trioxide (SO3) before entering the scrubber. SO3 further converts to sulfuric acid (H2SO4) and generates a submicron liquid mist upon quenching the gas. New ground level pollutant regulations require removal of sulfuric acid mist before exhausting the flue gas to atmosphere. A multi-pollutant solution is needed to remove both SO2 and sulfuric acid mist.

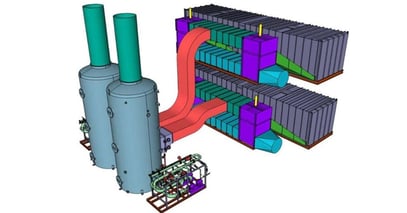

BP Amoco was engaged in expanding production capacity for purified terephthalic acid (PTA) at the CAPCO 6 and Zhuhai 1 petrochemical plants in China. PTA is used in the manufacture of polyester resin and polyethylene terephthalate (PET) plastic bottles. It is also widely used in the pharmaceutical, food, textile and packaging industries. The expansion projects were part of efforts to achieve process simplifications and lower capital costs. Project goals were to reduce plot area and the number of equipment pieces by 40%

BP Amoco was engaged in expanding production capacity for purified terephthalic acid (PTA) at the CAPCO 6 and Zhuhai 1 petrochemical plants in China. PTA is used in the manufacture of polyester resin and polyethylene terephthalate (PET) plastic bottles. It is also widely used in the pharmaceutical, food, textile and packaging industries. The expansion projects were part of efforts to achieve process simplifications and lower capital costs. Project goals were to reduce plot area and the number of equipment pieces by 40% The customer selected a custom engineered Envitech horizonal quencher. The material of construction is Hastelloy C276 to provide corrosion resistance at high inlet temperatures. A proprietary internal water injection and throat design splits the stream inside the vessel to ensure turbulence for mixing gases and water. Gases accelerate through the throat areas in combination with a recirculated water spray system. A small pressure drop cools gases over a wide flow rate operating range and minimizes the number of nozzles. The water spray header is removable to facilitate nozzle replacement and maintenance. The vessel is 13 feet in diameter in a horizontal arrangement. This allows the quencher to be shop fabricated so that inspection and quality assurance are done in a controlled environment. The unit is shipped as one piece.

The customer selected a custom engineered Envitech horizonal quencher. The material of construction is Hastelloy C276 to provide corrosion resistance at high inlet temperatures. A proprietary internal water injection and throat design splits the stream inside the vessel to ensure turbulence for mixing gases and water. Gases accelerate through the throat areas in combination with a recirculated water spray system. A small pressure drop cools gases over a wide flow rate operating range and minimizes the number of nozzles. The water spray header is removable to facilitate nozzle replacement and maintenance. The vessel is 13 feet in diameter in a horizontal arrangement. This allows the quencher to be shop fabricated so that inspection and quality assurance are done in a controlled environment. The unit is shipped as one piece.

a secondary feed tank and secondary make-up tank. Combined vent gases contain up to 1,500 ppmv (24 lb/hr) of Hydrogen Sulfide (H2S) in air.

a secondary feed tank and secondary make-up tank. Combined vent gases contain up to 1,500 ppmv (24 lb/hr) of Hydrogen Sulfide (H2S) in air.  Vent gases enter the bottom of the absorber and travels vertically upward. A removable spray nozzle in the quench zone pre-scrubs and cools the process vent stream. Recirculated water sprayed over the packed bed mixes with counter current upward flowing gas. A dilute solution of sodium hydroxide (NaOH) and sodium hypochlorite (NaOCl) metered into the recirculation line neutralizes and oxidizes acid gases. Chemical addition is controlled by pH and ORP.

Vent gases enter the bottom of the absorber and travels vertically upward. A removable spray nozzle in the quench zone pre-scrubs and cools the process vent stream. Recirculated water sprayed over the packed bed mixes with counter current upward flowing gas. A dilute solution of sodium hydroxide (NaOH) and sodium hypochlorite (NaOCl) metered into the recirculation line neutralizes and oxidizes acid gases. Chemical addition is controlled by pH and ORP.