I posted previous blogs discussing the South Coast Air Quality Management District (SCAQMD) Regional Clean Air Incentives Market RECLAIM program and the A&WMA/AQMD SOx Control Technology Conference held at Diamond Bar, CA on March 17th. During the conference I participated as a panel member to present Envitech’s Ultra-Low SO2 scrubber design. I will also be giving this presentation at the upcoming International Conference on Thermal Treatment Technologies (IT3) in Jacksonville, FL, May 10-13, 2011 and again at the Annual Air & Waste Management Conference in Orlando, FL June 21-24, 2011. Envitech will have a booth at the IT3 conference.

Management District (SCAQMD) Regional Clean Air Incentives Market RECLAIM program and the A&WMA/AQMD SOx Control Technology Conference held at Diamond Bar, CA on March 17th. During the conference I participated as a panel member to present Envitech’s Ultra-Low SO2 scrubber design. I will also be giving this presentation at the upcoming International Conference on Thermal Treatment Technologies (IT3) in Jacksonville, FL, May 10-13, 2011 and again at the Annual Air & Waste Management Conference in Orlando, FL June 21-24, 2011. Envitech will have a booth at the IT3 conference.

Below is an abstact for discussing the Ultra-Low SO2 scrubber design. You can click the icon below to download the paper.

High Efficiency SO2 Scrubber Design to Reduce Caustic Consumption

ABSTRACT

An industrial facility located in Southern California operates a thermal oxidizer to treat vapor recovery and waste gas streams containing sulfur compounds. The facility has an available source of alkali waste water which could be a potential scrubbing solution. Several technologies were evaluated to replace the existing control equipment for reducing SO2 emissions. Incentives exist for similar facilities with the South Coast Air Quality Management District (SCAQMD) Regional Clean Air Incentives Program (RECLAIM) to reduce SOx emissions below the facilities operating permit limits. The RECLAIM program is requiring plants to achieve less than 5 ppmv SO2 stack emissions and greater than 99% SO2 removal.

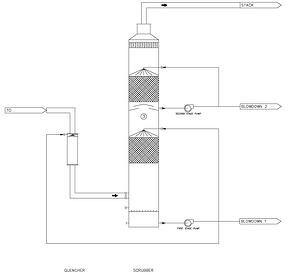

Plans are currently underway to replace the existing control equipment with a two stage packed bed scrubber system. This arrangement enables the plant to achieve very low emission limits and reduce caustic consumption by as much as 28% compared to a single stage scrubber. It also provides flexibility for future use of available alkali waste water to reduce caustic consumption by as much as 75% compared to a single stage caustic scrubber. This reduction will save an estimated $165,000 per year in operating cost. This paper will discuss the system design and how it achieves low outlet emissions while reducing overall chemical consumption. It will also discuss several other design considerations and benefits. The design approach provides a viable alternative for other Southern California facilities impacted by the SOx RECLAIM program as well as facilities in other regions.

Click on below icon to download whitepaper.

one of the conference sessions for the

one of the conference sessions for the  Market (

Market ( es related to SOx and the recently amended SOx RECLAIM program. I will be giving a presentation on an innovative SO2 scrubber design used at an industrial facility in Southern California to remove SO2 from a thermal oxidizer. The SO2 scrubber is designed to achieve low outlet emissions below 5 ppmv and greater than 99% removal efficiency. The presentation will discuss the advantages and benefits of the design, including reduction in caustic consumption. Continued efforts to deploy better technology and reduce emissions will enable clearer skies in the face of growing populations.

es related to SOx and the recently amended SOx RECLAIM program. I will be giving a presentation on an innovative SO2 scrubber design used at an industrial facility in Southern California to remove SO2 from a thermal oxidizer. The SO2 scrubber is designed to achieve low outlet emissions below 5 ppmv and greater than 99% removal efficiency. The presentation will discuss the advantages and benefits of the design, including reduction in caustic consumption. Continued efforts to deploy better technology and reduce emissions will enable clearer skies in the face of growing populations. Treatment (IT3) Conference in San Francisco, CA and the

Treatment (IT3) Conference in San Francisco, CA and the

Treatment (IT3) Conference in San Francisco, CA on wet scrubbers for gasification. Below is the paper abstract. A free download of the paper and presentation is available by clicking the links below. The paper discusses two common tar management approaches regarding syngas cleaning:

Treatment (IT3) Conference in San Francisco, CA on wet scrubbers for gasification. Below is the paper abstract. A free download of the paper and presentation is available by clicking the links below. The paper discusses two common tar management approaches regarding syngas cleaning:

I gave recent presentations at the International Thermal Treatment (IT3) Conference in San Francisco and the Annual

I gave recent presentations at the International Thermal Treatment (IT3) Conference in San Francisco and the Annual

house gases. One aspect of this technology is the use of coal dryers to dry the coal before feeding it into the gasifier. This requires a coal dryer scrubber which can be comprised of a Venturi scrubber followed by a condenser tower shown in the sketch.

house gases. One aspect of this technology is the use of coal dryers to dry the coal before feeding it into the gasifier. This requires a coal dryer scrubber which can be comprised of a Venturi scrubber followed by a condenser tower shown in the sketch. tower. Gas flow rates for these processes are relatively large and can exceed 300,000 acfm. Because of the large gas flows, the condenser tower can be as large as 20 feet in diameter or larger. The Venturi scrubber (shown in the image on the left) must have a special throat design to account for the large gas flow rate. The Venturi throat design is discussed in in the previous blog post for

tower. Gas flow rates for these processes are relatively large and can exceed 300,000 acfm. Because of the large gas flows, the condenser tower can be as large as 20 feet in diameter or larger. The Venturi scrubber (shown in the image on the left) must have a special throat design to account for the large gas flow rate. The Venturi throat design is discussed in in the previous blog post for

architecture and marine engineering firm. The panel was comprised of potential marine exhaust gas scrubber vendors. The intent of the workshop was to provide information to cruise line participants to assess the maturity of the industry and the likelihood that exhaust gas cleaning systems will be a feasible response to the challenges of changes in regulations.

architecture and marine engineering firm. The panel was comprised of potential marine exhaust gas scrubber vendors. The intent of the workshop was to provide information to cruise line participants to assess the maturity of the industry and the likelihood that exhaust gas cleaning systems will be a feasible response to the challenges of changes in regulations.