Venturi scrubbers are mechanical impaction devices that are used to control particulate on a wide range of applications. These include medical and hazardous waste incineration, potash drying, sewage sludge incineration and processing, coal drying, mineral wool manufacturing, and copper roasting to name a few. In one of my last blog posts I discussed a Venturi collision scrubber used to treat exhaust fumes of a Banbury mixer for rubber compounding. The Envitech collision scrubber is used in several Goodyear Tire manufacturing facilities around the world.

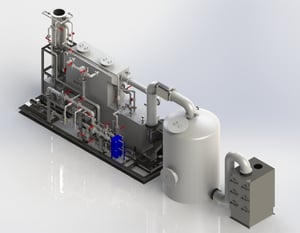

A recent new application is a horizontal Venturi scrubber for an aggregate asphalt drum dyer. The asphalt process is semi-stationary operating at fixed locations for several months at a time. The process is periodically broken down and moved to new locations for operation. The horizontal arrangement makes the horizontal Venturi scrubber an ideal solution for mobile applications. The equipment package is transportable on a single flatbed with only minor disassembly required for shipment and installation. The equipment is mounted onto a skid with pre-assembled piping and wiring to facilitate equipment mobility.

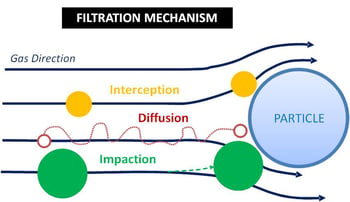

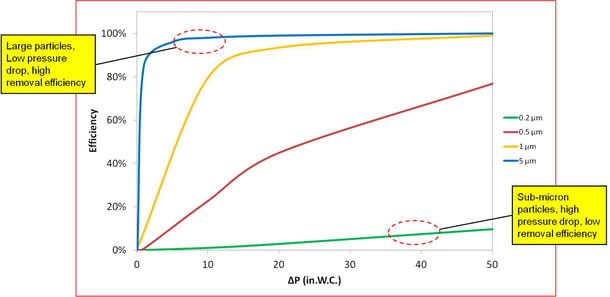

Particles are captured in the horizontal Venturi scrubber through a process of impaction by water droplets injected into the Venturi throat. A fraction of particulate laden water becomes entrained in the gas which has a droplet size distribution. The droplets are removed from the gas by a mist eliminator. There are two pathways for particles to escape capture by the scrubber. The first is penetration. Smaller particles lacking the mass for impaction penetrate through the scrubber. The second is through carry over of particulate laden water droplets. Droplet capture efficiency, or mist elimination, therefore impacts scrubber efficiency and overall plant emissions.

The horizontal Venturi scrubber uses a damper blade and actuator to maintain constant pressure drop across a wide range of gas flows. A high efficiency chevron mist eliminator removes particulate laden droplets before the gas exits the scrubber. A chevron mist eliminator removes greater than 99.9% of water droplets down to 27 microns with less than 0.25 inches W.C. of pressure drop. By comparison, a cyclonic separator requires several inches W.C. of pressure drop to remove 98% of 27 microns droplets. The advantages of a chevron mist eliminator are higher performance, larger turn down ratio, and lower pressure drop.

Envitech is currently building two new horizontal Venturi scrubbers sized for 45,000 acfm each for a peat drying operation. The compact design allows the scrubber to be easily installed inside a building. The high level of pre-assembly and lower profile reduces installation time and improves maintenance access for plant personnel. The horizontal Venturi scrubber can be a cost effective alternative to many processes that use a typical vertical arrangement.

Click on the link below to download Venturi scrubber literature.

Envitech developed a

Envitech developed a  Another example is a process vent scrubber for a blending facility in South Carolina that produces crop protection products for agricultural markets. The vent stream is 1,500 cfm and includes HCl and water soluble particulate greater than 3 micron in size. The Envitech lab scrubber was configured to include a low pressure drop Venturi for particulate control combined with a packed bed absorber for HCl control. The system includes instruments, control system, recirculation pump, pre-assembled piping, valves, and fittings, interconnect duct, ID fan, and stack.

Another example is a process vent scrubber for a blending facility in South Carolina that produces crop protection products for agricultural markets. The vent stream is 1,500 cfm and includes HCl and water soluble particulate greater than 3 micron in size. The Envitech lab scrubber was configured to include a low pressure drop Venturi for particulate control combined with a packed bed absorber for HCl control. The system includes instruments, control system, recirculation pump, pre-assembled piping, valves, and fittings, interconnect duct, ID fan, and stack.  A different use for a lab scrubber includes an ethylenediamine (

A different use for a lab scrubber includes an ethylenediamine (

Wet scrubbers are used to control hazardous air pollutants (HAPs) on many hospital, medical, and infectious waste incinerators (HMIWI). The Maximum Available Control Technology (MACT) standard for these incinerators was revised and became final in 2009. The new standard has the lowest emission limits for incinerators today. The limits exceeded the capability of systems designed to the previous standard with respect to particulate matter (PM), lead (Pd), cadmium (Cd), mercury (Hg), and dioxin/furans (D/F). By 2014 all existing medical waste incinerators were either shut down or upgraded to comply with the new standard. Envitech successfully upgraded four existing medical waste incinerators. A

Wet scrubbers are used to control hazardous air pollutants (HAPs) on many hospital, medical, and infectious waste incinerators (HMIWI). The Maximum Available Control Technology (MACT) standard for these incinerators was revised and became final in 2009. The new standard has the lowest emission limits for incinerators today. The limits exceeded the capability of systems designed to the previous standard with respect to particulate matter (PM), lead (Pd), cadmium (Cd), mercury (Hg), and dioxin/furans (D/F). By 2014 all existing medical waste incinerators were either shut down or upgraded to comply with the new standard. Envitech successfully upgraded four existing medical waste incinerators. A  rward will be new medical waste incinerators which have even more stringent, ultra-low emission limits. Building a new incinerator requires critical decisions on control technologies and permitting. The IT3/HWC paper reviews these issues for specific HAPs and discuss trade-offs between permitting a new medium size incinerator versus a large incinerator. An example is provided of an air pollution control system meeting the emission requirements for a new large medical waste incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. Envitech is also building gas cleaning systems for two new medium size medical waste incinerators for a research facility which integrate NOx control using ozone injection.

rward will be new medical waste incinerators which have even more stringent, ultra-low emission limits. Building a new incinerator requires critical decisions on control technologies and permitting. The IT3/HWC paper reviews these issues for specific HAPs and discuss trade-offs between permitting a new medium size incinerator versus a large incinerator. An example is provided of an air pollution control system meeting the emission requirements for a new large medical waste incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. Envitech is also building gas cleaning systems for two new medium size medical waste incinerators for a research facility which integrate NOx control using ozone injection.

Ethylene amines are one of the major chemical building blocks. Ethylene amines include ethylenediamine (EDA), diethylenetriamine (DETA), triethyltriamine (TETA) as well as other longer chained ethylene amines. Amongst its many uses, ethylene amine is one of the two principal chemical ingredients in making ethylenediaminetetracetic acid (EDTA), the most common chelating agent in the world. Diamines are also used in the manufacture of the ubiquitious textile Nylon. Due to its excellent properties, it is also used extensively in the asphalt, petrochemical, rubber, pesticide, and paper industries.

Ethylene amines are one of the major chemical building blocks. Ethylene amines include ethylenediamine (EDA), diethylenetriamine (DETA), triethyltriamine (TETA) as well as other longer chained ethylene amines. Amongst its many uses, ethylene amine is one of the two principal chemical ingredients in making ethylenediaminetetracetic acid (EDTA), the most common chelating agent in the world. Diamines are also used in the manufacture of the ubiquitious textile Nylon. Due to its excellent properties, it is also used extensively in the asphalt, petrochemical, rubber, pesticide, and paper industries.

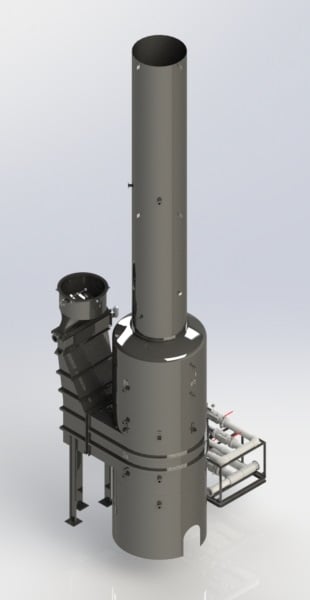

Banbury mixers are used, for instance, to compound rubber material for manufacturing automobile tires. Uncontrolled fumes from the mixers can create a nuisance by settling around the facility. Envitech’s Venturi collision scrubber has been used to control these fumes. The figure on the right shows a typical Venturi collision scrubber for a 25,000 cfm mixer exhaust. The scrubber separates the exhaust into two streams internal to the scrubber. The streams are then directed to two opposing Venturi throats. Recirculated water injected into each throat is atomized into fine droplets as the gas is accelerated. Fume particles and droplets collide and are captured by the atomized water as the steams are recombined into a third Venturi throat. A diffusion section redistributes the gas to a horizontal chevron style mist eliminator to remove entrained water droplets. Water is collected and drained into a common sump and recirculated back to the Venturi throats. A blowdown stream purges the collected material.

Banbury mixers are used, for instance, to compound rubber material for manufacturing automobile tires. Uncontrolled fumes from the mixers can create a nuisance by settling around the facility. Envitech’s Venturi collision scrubber has been used to control these fumes. The figure on the right shows a typical Venturi collision scrubber for a 25,000 cfm mixer exhaust. The scrubber separates the exhaust into two streams internal to the scrubber. The streams are then directed to two opposing Venturi throats. Recirculated water injected into each throat is atomized into fine droplets as the gas is accelerated. Fume particles and droplets collide and are captured by the atomized water as the steams are recombined into a third Venturi throat. A diffusion section redistributes the gas to a horizontal chevron style mist eliminator to remove entrained water droplets. Water is collected and drained into a common sump and recirculated back to the Venturi throats. A blowdown stream purges the collected material.

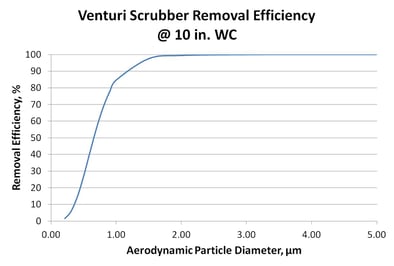

Venturi. It indicates that nearly all particles > 2 micron in size are removed by the Venturi. Performance drops off dramatically, however, for smaller particles. Mechanisms for particulate removal by a Venturi scrubber are discussed in more detail in an earlier

Venturi. It indicates that nearly all particles > 2 micron in size are removed by the Venturi. Performance drops off dramatically, however, for smaller particles. Mechanisms for particulate removal by a Venturi scrubber are discussed in more detail in an earlier  pressure drop over a minimum and maximum gas flow rate. The damper position is governed by proportional-integral-derivative control based on the differential pressure across the throat.

pressure drop over a minimum and maximum gas flow rate. The damper position is governed by proportional-integral-derivative control based on the differential pressure across the throat.

A common application for small scrubber systems is an emergency vent scrubber for l

A common application for small scrubber systems is an emergency vent scrubber for l

A Venturi scrubber is a common air pollution control device that is used to remove particulate. Because it is a wet scrubber, collected particulate is purged in a liquid discharge stream called the blowdown.

A Venturi scrubber is a common air pollution control device that is used to remove particulate. Because it is a wet scrubber, collected particulate is purged in a liquid discharge stream called the blowdown.

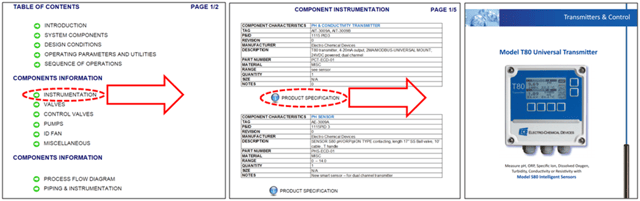

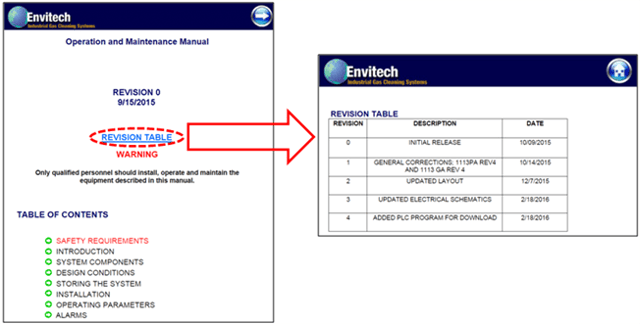

present several problems – they may be easily lost or damaged; large three-ring binders that are difficult to search and cumbersome to carry; and lastly, red-lined changes and as-builts often are not captured in the final revision.

present several problems – they may be easily lost or damaged; large three-ring binders that are difficult to search and cumbersome to carry; and lastly, red-lined changes and as-builts often are not captured in the final revision.