On March 18th, 2010 I participated on a panel discussion for the Cruise Lines International Association's Inc. (CLIA) Exhaust Gas Scrubber (EGS) Workshop in Miami, Fl. The workshop was professionally managed by BMT Designers & Planners, a navy architecture and marine engineering firm. The panel was comprised of potential marine exhaust gas scrubber vendors. The intent of the workshop was to provide information to cruise line participants to assess the maturity of the industry and the likelihood that exhaust gas cleaning systems will be a feasible response to the challenges of changes in regulations.

architecture and marine engineering firm. The panel was comprised of potential marine exhaust gas scrubber vendors. The intent of the workshop was to provide information to cruise line participants to assess the maturity of the industry and the likelihood that exhaust gas cleaning systems will be a feasible response to the challenges of changes in regulations.

The industry is evaluating alternatives for meeting upcoming SOx emission limits under Annex VI of Marpol 73/78. The SOx emission limits will require ships to achieve at least a SOx reduction equivalent to 0.1% sulfur fuel by 2015. This requirement can be met by using more expensive, low sulfur fuel, or by scrubbing the exhaust gas stream. The rules essentially require > 97% SOx removal assuming 3.5% sulfur fuel. The International Maritime Organization (IMO) has issued Guidelines for Exhaust Gas Cleaning Systems, Annex 4, Resolution MEPC.170(57), adopted April 4th, 2008 to specify the requirements for testing, survey certification, and verification of exhaust gas cleaning (EGS) systems to ensure compliance with Annex VI.

Envitech first started evaluating the marine scrubber application in early 2008 at the request of one of the major cruise lines. The cruise line was interested in working with a company that could apply industrial air pollution control equipment experience to marine diesel exhaust streams on board a ship. Envitech has deployed many particulate and acid gas scrubbers on a wide range of combustion processes including a seawater scrubber for an industrial waste incinerator at a pharmaceutical plant. Many of these systems are similar process requirements for a diesel engine exhaust. As a result of our evaluation Envitech developed, and recently filed a patent application for, the Hysea Marine Scrubber which is a hybrid seawater scrubber system. We introduced this technology to the industry during the CLIA EGS workshop.

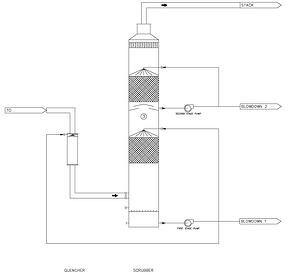

The Hysea Marine Scrubber uses available seawater alkalinity to scrub SOx. The system is chemically assisted with caustic solution (NaOH) to achieve high SOx removal and reduced water flow rates. The chemical consumption is minimal and estimated to be less than 7% of the usage of a closed loop, recirculation system. The system is designed to provide flexibility to operate in two modes:

-

Open Loop/Caustic Reduced Mode - Continuous, once-though liquid discharge.

-

Closed loop/bunkering Mode - Re-circulated seawater with a small discharge stream that can be temporarily bunkered on board the ship.

The discharge liquid in both operating modes is treated to meet regulatory requirements. Because chemical assistance with caustic substantially reduces the water flow rate, the water treatment system becomes more manageable on board a ship. The water treatment system also re-oxygenates the water to meet chemical oxygen demand (COD) standards.

The table below shows a comparison of three different marine scrubber configurations, including:

-

Open Loop - Using once through seawater

-

Closed Loop - Using re-circulated water

-

HySea Marine Scrubber - Using chemically assisted Seawater

| ITEM |

OPEN LOOP |

CLOSED LOOP |

HYSEA |

Water

Open Loop Mode

Closed Loop Mode |

Sea Water

Once-Through

- |

Fresh Water

Re-circulated

- |

Sea Water

Once-through

Re-circulated |

Blowdown, gpm

Open Loop Mode

Closed Loop Mode |

10,000

- |

-

5 |

2,300

5 |

Energy Consumption, kW

Open Loop Mode

Closed Loop Mode |

290

- |

45

- |

90

45 |

Caustic Consumption

(est. average), gph

Open Loop Mode

Closed Loop Mode |

0

- |

-

60 |

4

60 |

A comparison of the operating parameters highlights the reduced water and power consumption of the hybrid system compared to an open loop system. It also shows the substantial caustic reduction compared to a closed loop system. The main advantages of the Hysea Marine scrubber include:

Although the Hysea scrubber was designed for ship board use for a diesel engine exhaust, the same design principals also apply to acid gas scrubbing for land based industrial processes that have access to seawater.

A lot of interest in Marine exhaust gas cleaning systems was expressed during the EGS workshop. However, the cruise line industry is still evaluating the full range of options for complying with Annex VI of Marpol 73/78. The general consensus of the panel participants is that exhaust gas cleaning is not only technically feasible, but provides a compelling financial case as a means for meeting the new regulations.

Please read our case study on reducing SO2 emissions for ships docked at ports by clicking the link below.

Photo Credit: Saint Seminole

The scrubber will be used for the Advanced Maritime Emissions Control System (AMECs) by Advanced Cleanup Technologies, Inc.. The system will undergo duration tests at the port during 2012 and 2013 with the goal of obtaining a verification certificate by the California Air Resources Board (CARB).

The scrubber will be used for the Advanced Maritime Emissions Control System (AMECs) by Advanced Cleanup Technologies, Inc.. The system will undergo duration tests at the port during 2012 and 2013 with the goal of obtaining a verification certificate by the California Air Resources Board (CARB).

Management District (

Management District (

one of the conference sessions for the

one of the conference sessions for the  Market (

Market ( es related to SOx and the recently amended SOx RECLAIM program. I will be giving a presentation on an innovative SO2 scrubber design used at an industrial facility in Southern California to remove SO2 from a thermal oxidizer. The SO2 scrubber is designed to achieve low outlet emissions below 5 ppmv and greater than 99% removal efficiency. The presentation will discuss the advantages and benefits of the design, including reduction in caustic consumption. Continued efforts to deploy better technology and reduce emissions will enable clearer skies in the face of growing populations.

es related to SOx and the recently amended SOx RECLAIM program. I will be giving a presentation on an innovative SO2 scrubber design used at an industrial facility in Southern California to remove SO2 from a thermal oxidizer. The SO2 scrubber is designed to achieve low outlet emissions below 5 ppmv and greater than 99% removal efficiency. The presentation will discuss the advantages and benefits of the design, including reduction in caustic consumption. Continued efforts to deploy better technology and reduce emissions will enable clearer skies in the face of growing populations. Treatment (IT3) Conference in San Francisco, CA on wet scrubbers for gasification. Below is the paper abstract. A free download of the paper and presentation is available by clicking the links below. The paper discusses two common tar management approaches regarding syngas cleaning:

Treatment (IT3) Conference in San Francisco, CA on wet scrubbers for gasification. Below is the paper abstract. A free download of the paper and presentation is available by clicking the links below. The paper discusses two common tar management approaches regarding syngas cleaning:

I gave recent presentations at the International Thermal Treatment (IT3) Conference in San Francisco and the Annual

I gave recent presentations at the International Thermal Treatment (IT3) Conference in San Francisco and the Annual

architecture and marine engineering firm. The panel was comprised of potential marine exhaust gas scrubber vendors. The intent of the workshop was to provide information to cruise line participants to assess the maturity of the industry and the likelihood that exhaust gas cleaning systems will be a feasible response to the challenges of changes in regulations.

architecture and marine engineering firm. The panel was comprised of potential marine exhaust gas scrubber vendors. The intent of the workshop was to provide information to cruise line participants to assess the maturity of the industry and the likelihood that exhaust gas cleaning systems will be a feasible response to the challenges of changes in regulations. referred to as smog. It is most commonly produced in combustion processes, but can also be generated in non-combustion processes like metal refining, picking baths, or nitric acid manufacturing to name a few. The following link:

referred to as smog. It is most commonly produced in combustion processes, but can also be generated in non-combustion processes like metal refining, picking baths, or nitric acid manufacturing to name a few. The following link:

The adjacent photo shows a 400 lb/hr medical waste incinerator scrubber with a Venturi inlet flow rate of 1,200 scfm. The reflux damper can be seen as the white horizontal duct from the ID fan outlet to the Venturi inlet on the right hand side of the rectangular condenser/absorber box.

The adjacent photo shows a 400 lb/hr medical waste incinerator scrubber with a Venturi inlet flow rate of 1,200 scfm. The reflux damper can be seen as the white horizontal duct from the ID fan outlet to the Venturi inlet on the right hand side of the rectangular condenser/absorber box.

Removal of the bulk particulate load - Removal of the bulk particulate load may be required if there is a high particulate concentration from the upstream process. This will be the case for secondary lead smelters, lead refining, and refinery sludge incinerators. Geothermal energy plants will not have this requirement. A bag-house will be used for secondary lead smelters and lead refining. A wet Venturi scrubber system can be used for refinery sludge incinerators Removal of the bulk particulate minimizes space-charge effects inside the WESP. Space-charge effects occur when particles interact and repel each other. This reduces WESP performance because it interferes with the migration of charged particle to the tube wall for collection.

Removal of the bulk particulate load - Removal of the bulk particulate load may be required if there is a high particulate concentration from the upstream process. This will be the case for secondary lead smelters, lead refining, and refinery sludge incinerators. Geothermal energy plants will not have this requirement. A bag-house will be used for secondary lead smelters and lead refining. A wet Venturi scrubber system can be used for refinery sludge incinerators Removal of the bulk particulate minimizes space-charge effects inside the WESP. Space-charge effects occur when particles interact and repel each other. This reduces WESP performance because it interferes with the migration of charged particle to the tube wall for collection.