As an equipment supplier of custom engineered wet scrubber equipment, Envitech frequently provides lunch and learns (L&L’s) to engineering companies to help educate engineers about the basics of available technology.

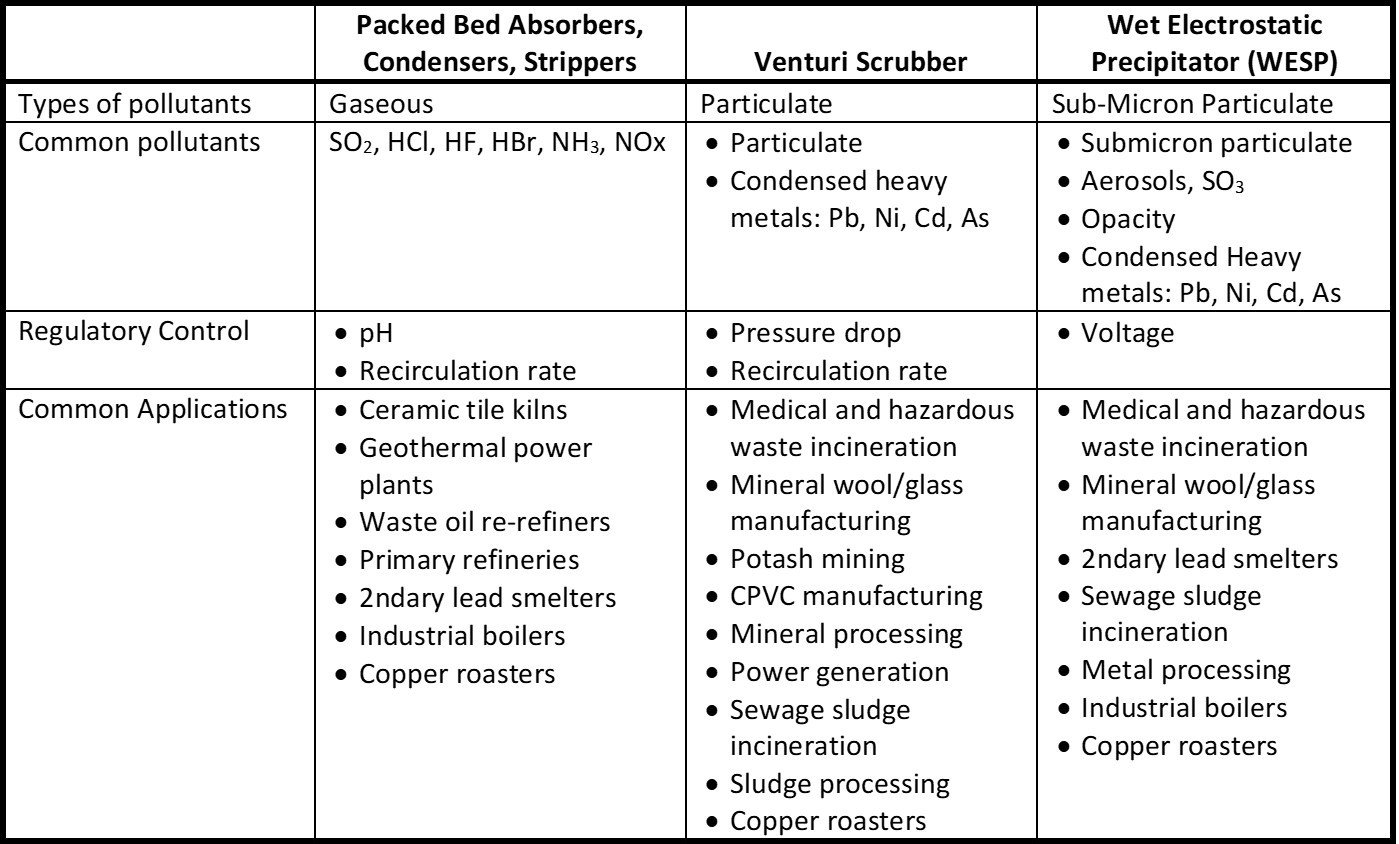

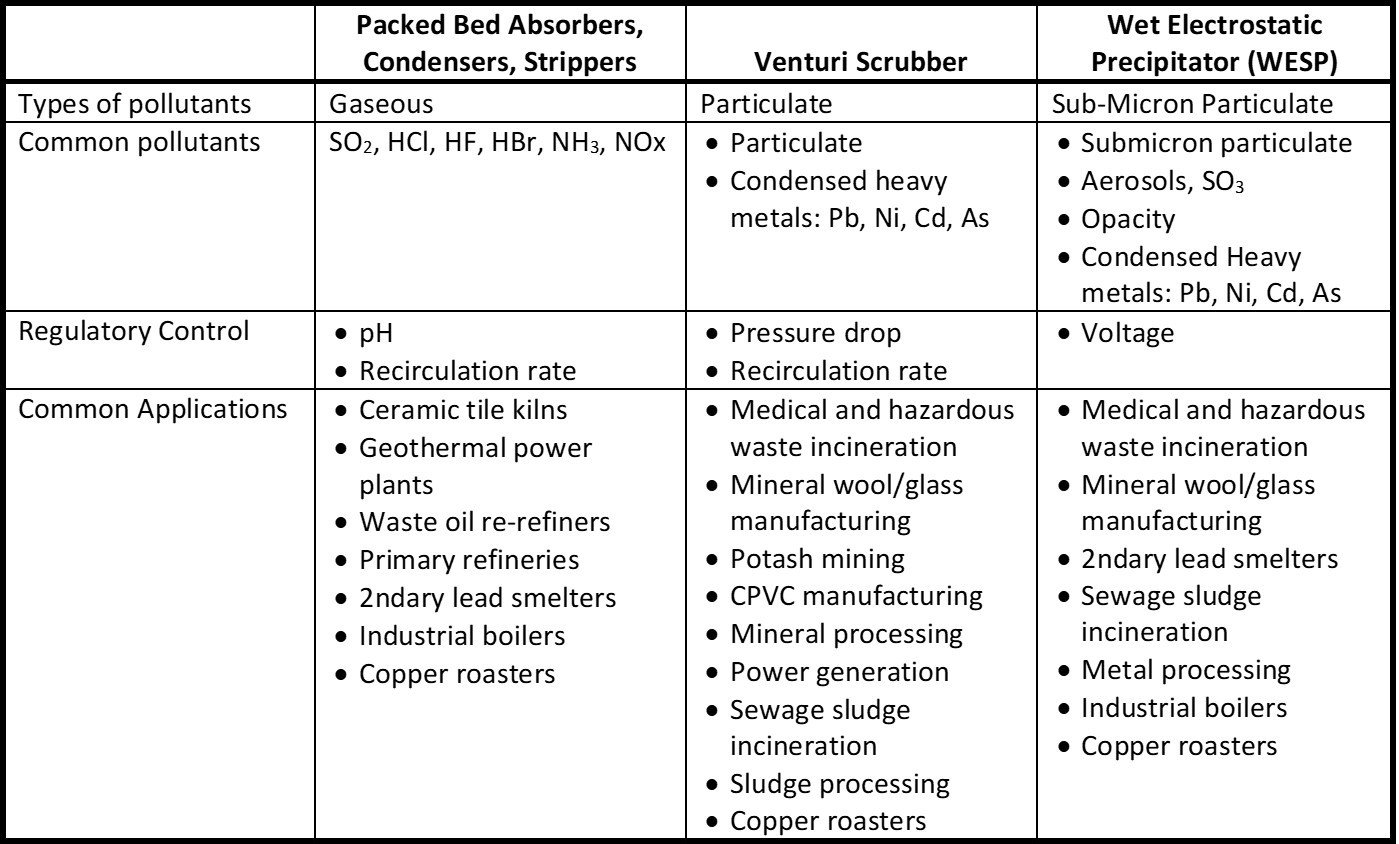

Figure 1 below is a summary chart of predominant wet scrubber technology options. The main product categories include packed bed absorbers, Venturi scrubbers, and wet electrostatic precipitators (WESPs). Each wet scrubber type serves a different purpose and is used in different circumstances. For instance, packed bed absorbers are primarily used to remove gaseous emissions like SO2, HCl, or HF. We often receive packed bed absorber inquiries for particulate removal, however, this would be a misuse of technology. Packed bed absorbers remove some particulate but they are not nearly as efficient as other options.

Figure 1: Wet scrubber technology summary

Venturi scrubbers are used for particulate removal. Just like we sometimes receive packed bed absorber inquiries for particulate removal, we’ll occasionally get Venturi scrubber inquiries for acid gas removal. This would also be a misuse of technology. Venturi scrubbers achieve some acid gas removal, but they have poor mass transfer compared to a packed bed absorbers.

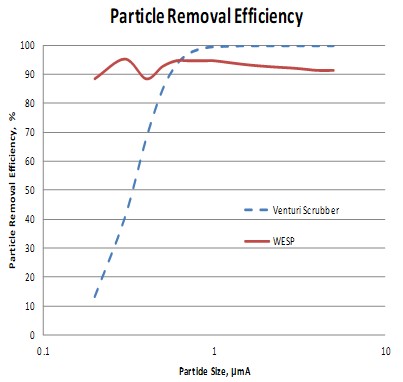

Venturi scrubbers use mechanical forces to remove particulate. Particles are captured through a process of impaction between particles in the gas and water droplets in the Venturi throat. A high differential velocity is created between particles and droplets by accelerating the gas in the throat. A pressure drop in the throat provides energy to capture the particles. Smaller particles less than 1 micron in size avoid capture by behaving like gas molecules and finding slip streams around the water droplets. Venturi scrubber performance drops offs exponentially for submicron particulate. Overall removal efficiency may be limited for a gas stream with a high concentration of submicron particulate. Venturi scrubbers are a good choice for industrial dryers or other applications with large size particulate.

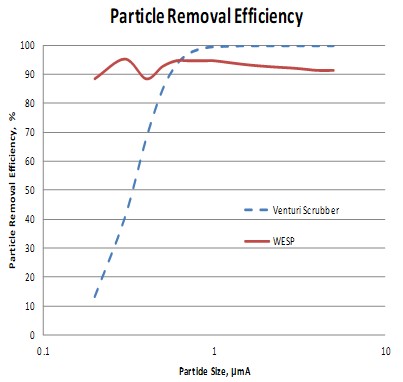

Wet electrostatic precipitator (WESP) are the third type of wet scrubber summarized in the table. Like Venturi scrubbers, they are also particulate removal devices. They differ from Venturi scrubbers in a couple of ways, 1.) electrical, not mechanical forces are used to capture particulate, and 2,) they are efficient at capturing submicron particulate. Figure 2 shows a performance comparison between a WESP and Venturi scrubber. It can be seen that performance drops off dramatically for Venturi scrubbers for particles less than 1 micron in size. WESP’s on the other hand remove particles regardless of particle size.

Figure 2: WESP, Venturi scrubber performance comparison versus particle size.

The summary in Figure 1 also shows how each wet scrubber technology differs in regulatory control. A packed bed absorber is typically controlled for recirculation flow rate and liquid pH. A Venturi scrubber is controlled by recirculation rate and pressure drop. A WESP is controlled by voltage. Control limits are typically spelled out in the operating permit.

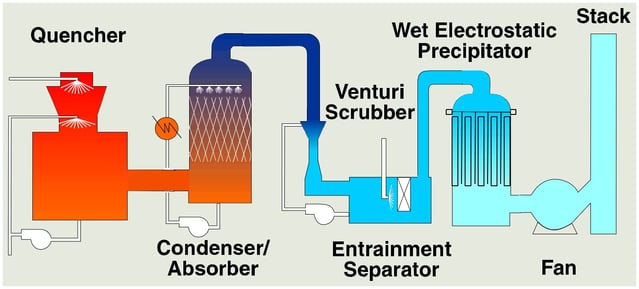

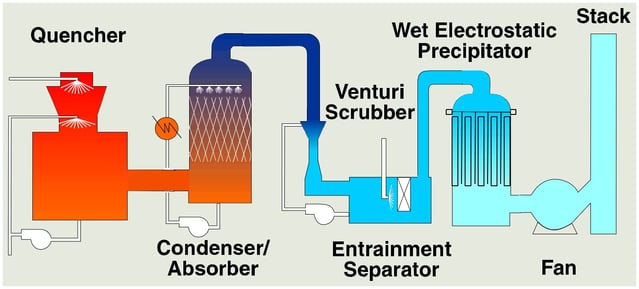

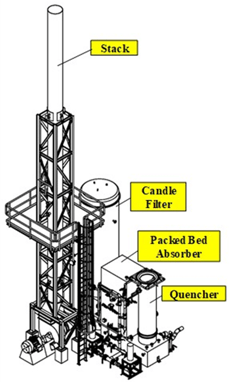

Finally, some examples of applications are given for each type of wet scrubber. It should be noted that there are many applications that have multiple types of pollutants. A hazardous waste incinerator, for instance, contains particulate, acid gases, and specific heavy metals like cadmium and lead. A fraction of particulate is submicron in size and difficult for a Venturi scrubber to remove. It is common for different types of wet scrubbers to be combined into a multi-pollutant device. Figure 3 shows a common arrangement for an incinerator scrubber. The gas is first cooled in a quencher. A packed bed absorber removes acid gases. A Venturi scrubber removes particulate and a WESP removes the submicron particulate and heavy metals.

Figure 3: Incinerator wet scrubber arrangement

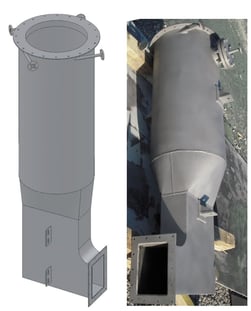

Wet scrubbers can also be combined with dry scrubbers in certain circumstances. An upstream bag-house can remove particulate followed by a packed bed absorber for acid gas removal. A cyclone can be used to knock out large particulate before using a Venturi scrubber for the remaining particulate. A cyclone helps to minimize blowdown and water consumption. In some cases, a dry filter or carbon bed absorber can be integrated downstream of a wet scrubber for mercury and/or dioxin/furan. Click here to read a blog piece about an example of a wet scrubber combined with a carbon bed.

This about covers wet scrubber basics. If you’re with an engineering company and want to discuss scheduling a lunch an learn, please give Envitech a call. You can click on the icon below for a set of Envitech brochures.

Click on the icon below to download an Envitech brochure.

Vintage Petroleum, LLC, a subsidiary of Occidental Petroleum Corporation operates oil and gas fields in Lost Hills, California, northwest of Bakersfield. The fields operate steam boilers that use nearby canal water. High concentrations of dissolved oxygen in the canal water caused excessive corrosion in the boilers.

Vintage Petroleum, LLC, a subsidiary of Occidental Petroleum Corporation operates oil and gas fields in Lost Hills, California, northwest of Bakersfield. The fields operate steam boilers that use nearby canal water. High concentrations of dissolved oxygen in the canal water caused excessive corrosion in the boilers.

nclosed to capture process emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) are released during shredding, including small amounts of halogenated compounds.

nclosed to capture process emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) are released during shredding, including small amounts of halogenated compounds.

(TO) that treats a rich stream of chlorinated compounds and an organic silicon compound. HCl and silicon dioxide (SiO2) particulate are formed during combustion. The exhaust is treated by a Hastelloy evaporative quencher followed by a caustic scrubber.

(TO) that treats a rich stream of chlorinated compounds and an organic silicon compound. HCl and silicon dioxide (SiO2) particulate are formed during combustion. The exhaust is treated by a Hastelloy evaporative quencher followed by a caustic scrubber.

Waste oil is recycled and refined into low sulfur marine diesel and other industrial fuels at West Coast refineries. Waste gas is sent to thermal oxidizers for volatile organic compound (VOC) destruction. Sulfur compounds in the waste gas are oxidized to SO2 and removed by a packed bed scrubber. A fraction of SO2 converts to sulfur trioxide (SO3) before entering the scrubber. SO3 further converts to sulfuric acid (H2SO4) and generates a submicron liquid mist upon quenching the gas. New ground level pollutant regulations require removal of sulfuric acid mist before exhausting the flue gas to atmosphere. A multi-pollutant solution is needed to remove both SO2 and sulfuric acid mist.

Waste oil is recycled and refined into low sulfur marine diesel and other industrial fuels at West Coast refineries. Waste gas is sent to thermal oxidizers for volatile organic compound (VOC) destruction. Sulfur compounds in the waste gas are oxidized to SO2 and removed by a packed bed scrubber. A fraction of SO2 converts to sulfur trioxide (SO3) before entering the scrubber. SO3 further converts to sulfuric acid (H2SO4) and generates a submicron liquid mist upon quenching the gas. New ground level pollutant regulations require removal of sulfuric acid mist before exhausting the flue gas to atmosphere. A multi-pollutant solution is needed to remove both SO2 and sulfuric acid mist.

a secondary feed tank and secondary make-up tank. Combined vent gases contain up to 1,500 ppmv (24 lb/hr) of Hydrogen Sulfide (H2S) in air.

a secondary feed tank and secondary make-up tank. Combined vent gases contain up to 1,500 ppmv (24 lb/hr) of Hydrogen Sulfide (H2S) in air.  Vent gases enter the bottom of the absorber and travels vertically upward. A removable spray nozzle in the quench zone pre-scrubs and cools the process vent stream. Recirculated water sprayed over the packed bed mixes with counter current upward flowing gas. A dilute solution of sodium hydroxide (NaOH) and sodium hypochlorite (NaOCl) metered into the recirculation line neutralizes and oxidizes acid gases. Chemical addition is controlled by pH and ORP.

Vent gases enter the bottom of the absorber and travels vertically upward. A removable spray nozzle in the quench zone pre-scrubs and cools the process vent stream. Recirculated water sprayed over the packed bed mixes with counter current upward flowing gas. A dilute solution of sodium hydroxide (NaOH) and sodium hypochlorite (NaOCl) metered into the recirculation line neutralizes and oxidizes acid gases. Chemical addition is controlled by pH and ORP.

food waste per day into 100 MMBtu/d of renewable energy biogas. The digester is sited near campus at a decommissioned landfill.

food waste per day into 100 MMBtu/d of renewable energy biogas. The digester is sited near campus at a decommissioned landfill.  ith HMI, pre-assembled pump, piping, valves and fittings, ID fan with VFD, and free-standing interconnect duct and stack.

ith HMI, pre-assembled pump, piping, valves and fittings, ID fan with VFD, and free-standing interconnect duct and stack.

. Batches occur over a 20-hour period and ammonia concentrations varies from <1 to 96%.

. Batches occur over a 20-hour period and ammonia concentrations varies from <1 to 96%.

reduce organic compounds using a catalyst. In-situ regeneration is desired to restore the catalyst for additional processing. This improves operational efficiency and safety. The facility is evaluating technology options to achieve this goal. One approach is to

reduce organic compounds using a catalyst. In-situ regeneration is desired to restore the catalyst for additional processing. This improves operational efficiency and safety. The facility is evaluating technology options to achieve this goal. One approach is to  is T316SS conforming to ASME B31.1. Welds are specified to be magnetically and X-ray tested using certified welders.

is T316SS conforming to ASME B31.1. Welds are specified to be magnetically and X-ray tested using certified welders.