Vintage Petroleum, LLC, a subsidiary of Occidental Petroleum Corporation operates oil and gas fields in Lost Hills, California, northwest of Bakersfield. The fields operate steam boilers that use nearby canal water. High concentrations of dissolved oxygen in the canal water caused excessive corrosion in the boilers.

Vintage Petroleum, LLC, a subsidiary of Occidental Petroleum Corporation operates oil and gas fields in Lost Hills, California, northwest of Bakersfield. The fields operate steam boilers that use nearby canal water. High concentrations of dissolved oxygen in the canal water caused excessive corrosion in the boilers.

Vintage was looking for an effective means to reduce oxygen content in the canal water to prolong boiler life and reduce maintenance costs.

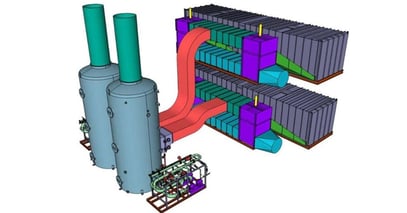

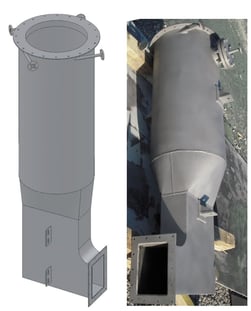

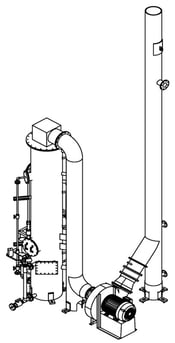

The customer selected Envitech to design and build two stripper towers. The towers use high pressure natural gas to strip oxygen from the canal water. The water is pumped 1,000 feet from the canal to the tower locations. After stripping to remove oxygen, the water is pumped to an existing fresh water tank.

The vessels are constructed of carbon steel with a 3/16 inch corrosion allowance and painted internally and externally. The

vessels are fabricated in accordance with ASME Code Section VIII Division I requirements and stamped. The maximum vessel design working pressure is 100 psig at a maximum design temperature of 300 °F and also designed for half vacuum.

The lower vessels are 6 feet in diameter. The upper packed bed sections are 4 feet in diameter. The overall vessel height is 27 feet.

The first system was installed in 2013. The second system was installed in 2014. Both systems are operational and the facility reports success in prolonging boiler life. Designed to the parameters summarized in the adjacent table, the stripping towers resulted in an innovative process solution to solve a unique operational problem.

- Gas flow rate, mscfd: 328

- Water flow rate, gpm: 450

- Operating temperature, oF: 60 to 120

- Operating pressure, psig: 40

- Oxygen content of in stripping gas, ppm: 70

- Dissolved oxygen content in canal water, mg/L: 9

- Dissolved oxygen removal: > 90%

Click on the link below to download literature about this application.

nclosed to capture process emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) are released during shredding, including small amounts of halogenated compounds.

nclosed to capture process emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs) are released during shredding, including small amounts of halogenated compounds.

(TO) that treats a rich stream of chlorinated compounds and an organic silicon compound. HCl and silicon dioxide (SiO2) particulate are formed during combustion. The exhaust is treated by a Hastelloy evaporative quencher followed by a caustic scrubber.

(TO) that treats a rich stream of chlorinated compounds and an organic silicon compound. HCl and silicon dioxide (SiO2) particulate are formed during combustion. The exhaust is treated by a Hastelloy evaporative quencher followed by a caustic scrubber.

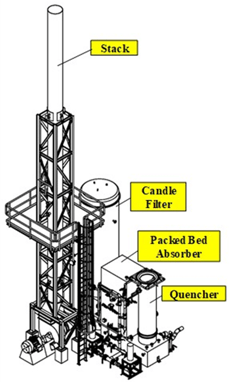

Waste oil is recycled and refined into low sulfur marine diesel and other industrial fuels at West Coast refineries. Waste gas is sent to thermal oxidizers for volatile organic compound (VOC) destruction. Sulfur compounds in the waste gas are oxidized to SO2 and removed by a packed bed scrubber. A fraction of SO2 converts to sulfur trioxide (SO3) before entering the scrubber. SO3 further converts to sulfuric acid (H2SO4) and generates a submicron liquid mist upon quenching the gas. New ground level pollutant regulations require removal of sulfuric acid mist before exhausting the flue gas to atmosphere. A multi-pollutant solution is needed to remove both SO2 and sulfuric acid mist.

Waste oil is recycled and refined into low sulfur marine diesel and other industrial fuels at West Coast refineries. Waste gas is sent to thermal oxidizers for volatile organic compound (VOC) destruction. Sulfur compounds in the waste gas are oxidized to SO2 and removed by a packed bed scrubber. A fraction of SO2 converts to sulfur trioxide (SO3) before entering the scrubber. SO3 further converts to sulfuric acid (H2SO4) and generates a submicron liquid mist upon quenching the gas. New ground level pollutant regulations require removal of sulfuric acid mist before exhausting the flue gas to atmosphere. A multi-pollutant solution is needed to remove both SO2 and sulfuric acid mist.

BP Amoco was engaged in expanding production capacity for purified terephthalic acid (PTA) at the CAPCO 6 and Zhuhai 1 petrochemical plants in China. PTA is used in the manufacture of polyester resin and polyethylene terephthalate (PET) plastic bottles. It is also widely used in the pharmaceutical, food, textile and packaging industries. The expansion projects were part of efforts to achieve process simplifications and lower capital costs. Project goals were to reduce plot area and the number of equipment pieces by 40%

BP Amoco was engaged in expanding production capacity for purified terephthalic acid (PTA) at the CAPCO 6 and Zhuhai 1 petrochemical plants in China. PTA is used in the manufacture of polyester resin and polyethylene terephthalate (PET) plastic bottles. It is also widely used in the pharmaceutical, food, textile and packaging industries. The expansion projects were part of efforts to achieve process simplifications and lower capital costs. Project goals were to reduce plot area and the number of equipment pieces by 40% The customer selected a custom engineered Envitech horizonal quencher. The material of construction is Hastelloy C276 to provide corrosion resistance at high inlet temperatures. A proprietary internal water injection and throat design splits the stream inside the vessel to ensure turbulence for mixing gases and water. Gases accelerate through the throat areas in combination with a recirculated water spray system. A small pressure drop cools gases over a wide flow rate operating range and minimizes the number of nozzles. The water spray header is removable to facilitate nozzle replacement and maintenance. The vessel is 13 feet in diameter in a horizontal arrangement. This allows the quencher to be shop fabricated so that inspection and quality assurance are done in a controlled environment. The unit is shipped as one piece.

The customer selected a custom engineered Envitech horizonal quencher. The material of construction is Hastelloy C276 to provide corrosion resistance at high inlet temperatures. A proprietary internal water injection and throat design splits the stream inside the vessel to ensure turbulence for mixing gases and water. Gases accelerate through the throat areas in combination with a recirculated water spray system. A small pressure drop cools gases over a wide flow rate operating range and minimizes the number of nozzles. The water spray header is removable to facilitate nozzle replacement and maintenance. The vessel is 13 feet in diameter in a horizontal arrangement. This allows the quencher to be shop fabricated so that inspection and quality assurance are done in a controlled environment. The unit is shipped as one piece.

a secondary feed tank and secondary make-up tank. Combined vent gases contain up to 1,500 ppmv (24 lb/hr) of Hydrogen Sulfide (H2S) in air.

a secondary feed tank and secondary make-up tank. Combined vent gases contain up to 1,500 ppmv (24 lb/hr) of Hydrogen Sulfide (H2S) in air.  Vent gases enter the bottom of the absorber and travels vertically upward. A removable spray nozzle in the quench zone pre-scrubs and cools the process vent stream. Recirculated water sprayed over the packed bed mixes with counter current upward flowing gas. A dilute solution of sodium hydroxide (NaOH) and sodium hypochlorite (NaOCl) metered into the recirculation line neutralizes and oxidizes acid gases. Chemical addition is controlled by pH and ORP.

Vent gases enter the bottom of the absorber and travels vertically upward. A removable spray nozzle in the quench zone pre-scrubs and cools the process vent stream. Recirculated water sprayed over the packed bed mixes with counter current upward flowing gas. A dilute solution of sodium hydroxide (NaOH) and sodium hypochlorite (NaOCl) metered into the recirculation line neutralizes and oxidizes acid gases. Chemical addition is controlled by pH and ORP.

food waste per day into 100 MMBtu/d of renewable energy biogas. The digester is sited near campus at a decommissioned landfill.

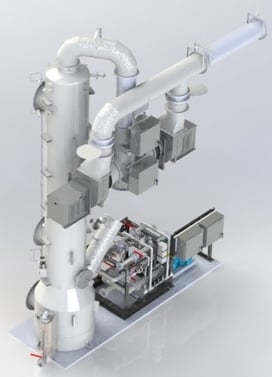

food waste per day into 100 MMBtu/d of renewable energy biogas. The digester is sited near campus at a decommissioned landfill.  ith HMI, pre-assembled pump, piping, valves and fittings, ID fan with VFD, and free-standing interconnect duct and stack.

ith HMI, pre-assembled pump, piping, valves and fittings, ID fan with VFD, and free-standing interconnect duct and stack.

into a consistent granular media. The media is used as a natural microbial carrier to inoculate millions of acres of food crops each year. The transformation process relies on drying harvested material in industrial rotary dryers. A fraction of the material becomes entrained in the flue gas as particulate emissions. The facility is expanding operations to double the capacity. A scrubber solution is needed to reduce total plant particulate emissions.

into a consistent granular media. The media is used as a natural microbial carrier to inoculate millions of acres of food crops each year. The transformation process relies on drying harvested material in industrial rotary dryers. A fraction of the material becomes entrained in the flue gas as particulate emissions. The facility is expanding operations to double the capacity. A scrubber solution is needed to reduce total plant particulate emissions. ers. The scrubbers are comprised of a variable throat Venturi scrubber and a chevron style entrainment separator mounted on an equipment skid. The scope of supply for each scrubber includes a control system, re-circulation pump with pre-assembled piping, valves and fittings. Instruments are pre-mounted in the piping where possible and pre-wired to a junction box on the skid. The horizontal configuration provides a compact design to fit inside the building with easy maintenance access to valves and instruments.

ers. The scrubbers are comprised of a variable throat Venturi scrubber and a chevron style entrainment separator mounted on an equipment skid. The scope of supply for each scrubber includes a control system, re-circulation pump with pre-assembled piping, valves and fittings. Instruments are pre-mounted in the piping where possible and pre-wired to a junction box on the skid. The horizontal configuration provides a compact design to fit inside the building with easy maintenance access to valves and instruments.

. Batches occur over a 20-hour period and ammonia concentrations varies from <1 to 96%.

. Batches occur over a 20-hour period and ammonia concentrations varies from <1 to 96%.

reduce organic compounds using a catalyst. In-situ regeneration is desired to restore the catalyst for additional processing. This improves operational efficiency and safety. The facility is evaluating technology options to achieve this goal. One approach is to

reduce organic compounds using a catalyst. In-situ regeneration is desired to restore the catalyst for additional processing. This improves operational efficiency and safety. The facility is evaluating technology options to achieve this goal. One approach is to  is T316SS conforming to ASME B31.1. Welds are specified to be magnetically and X-ray tested using certified welders.

is T316SS conforming to ASME B31.1. Welds are specified to be magnetically and X-ray tested using certified welders.