PROBLEM:

A Midwestern ceramic tile manufacturer needed an acid gas scrubber to treat the off gas from 3 kilns being installed at a new manufacturing plant. Each kiln was equal in size and emits HF, HCl, and SO2. The scrubber needed to remove > 98.5% of acid gases. The scope of supply included an ID Fan, interconnect duct, stack, control system, and pump skid. The facility was faced with the additional challenge of less than 22 ft of overhead space inside the building. A tight schedule required receipt of equipment in 16 weeks, including engineering. The customer operated other scrubbers at different facilities and reported difficulty in controlling the spray quenchers to cool and saturate the gas.

SOLUTION:

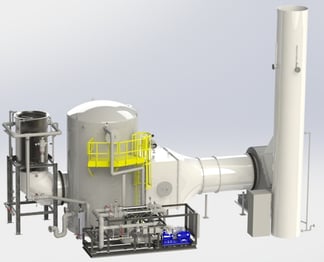

The customer selected an Envitech quencher/packed bed scrubber to meet their requirements. To eliminate difficulty in controlling gas cooling the scrubber used a proprietary, low pressure drop Venturi quencher. This provided a means to saturate the gas over a wide range of operating conditions and flow rates. The scrubber used a proprietary internal duct design with an outlet and entrainment separator at the bottom of the scrubber. This allowed the scrubber to fit in the low overhead space with no roof penetrations to minimize installation cost and time. Other equipment features included:

- Quencher design to capture > 90% of particulate > 3 microns.

- Skid mounted dual pumps (1 opr/1 spare) with pre-piped and valved instruments.

- Hydro-testing of piping assemblies.

- Instruments pre-wired to a junction box.

- Control System Factory Acceptance Test (FAT).

- High efficiency, low pressure drop packing with high void spaces to prevent material accumulation and fouling.

RESULTS:

The customer placed the order in June, 2015. The equipment shipped on time in October 2015 and arrived on site one week early, 15 weeks from order placement. The system will be operational in early 2016. Stack testing will confirm compliance with the performance guarantee summarized in the table below.

|

DESIGN |

VALUE |

|

Flow Rate, acfm |

70,000 |

|

Inlet Temp, oF |

482 |

|

HF Removal |

> 98.5% |

|

HCl Removal |

> 97% |

|

SO2 Removal |

> 53% |

To download a Free Case Study, please click on the icon below.

ogram

ogram

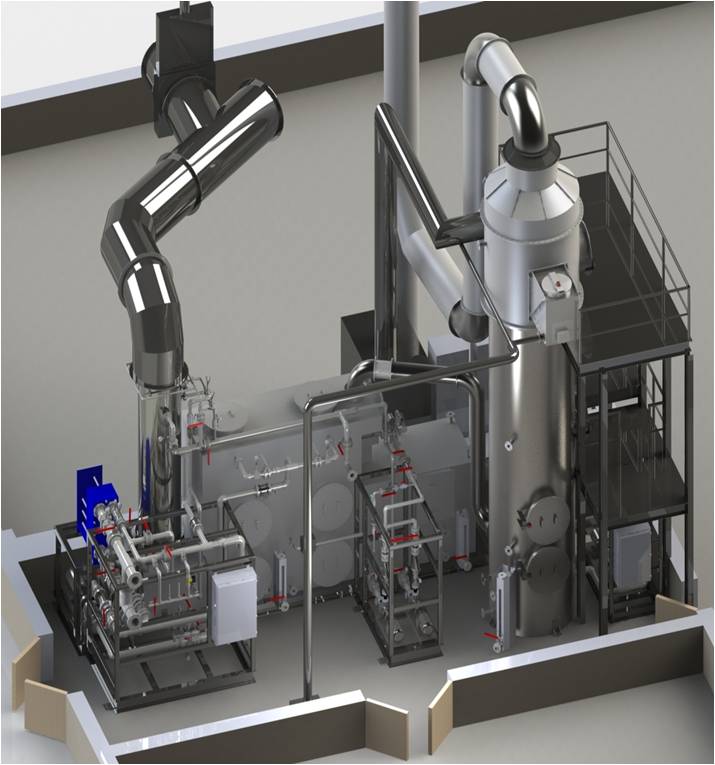

incinerator. The incinerator exhaust is ducted to a metal quencher (shown in the foreground). The hot gas enters the top of the quencher and flows vertically downward. The gas then elbows into the bottom of a vertical packed bed scrubber (shown in the background). The gas passes upward through the packed bed as re-circulated water flows downward, counter-current to the gas from the top of the packed bed. Water from the quencher and packed bed is collected in the sump and re-circulated back to the quencher and packed bed. An entrainment separator at the top of the scrubber removes entrained water droplets. After exiting the scrubber vessel, an interconnect duct transports the gas to a induced draft fan located at grade.

incinerator. The incinerator exhaust is ducted to a metal quencher (shown in the foreground). The hot gas enters the top of the quencher and flows vertically downward. The gas then elbows into the bottom of a vertical packed bed scrubber (shown in the background). The gas passes upward through the packed bed as re-circulated water flows downward, counter-current to the gas from the top of the packed bed. Water from the quencher and packed bed is collected in the sump and re-circulated back to the quencher and packed bed. An entrainment separator at the top of the scrubber removes entrained water droplets. After exiting the scrubber vessel, an interconnect duct transports the gas to a induced draft fan located at grade.

cinerator and waste heat boiler treats the TGTU off-gas before it is exhausted to atmosphere. During normal operations, there is very little SO2 emissions due to the high sulfur recovery. However, TGTU upsets can occur several times per year which sends unrecovered sulfur to the incinerator. During these upsets, SO2 emissions can be as high as 1 tph or more for a period of 8 to 12 hours.

cinerator and waste heat boiler treats the TGTU off-gas before it is exhausted to atmosphere. During normal operations, there is very little SO2 emissions due to the high sulfur recovery. However, TGTU upsets can occur several times per year which sends unrecovered sulfur to the incinerator. During these upsets, SO2 emissions can be as high as 1 tph or more for a period of 8 to 12 hours.

In 2012 Envitech designed and built a

In 2012 Envitech designed and built a

copper resources challenged by high levels of arsenic. Mining operations may incur penalties for arsenic in concentrates that exceed a certain amount. As ore with low levels of arsenic is depleted, these penalties will continue to rise.

copper resources challenged by high levels of arsenic. Mining operations may incur penalties for arsenic in concentrates that exceed a certain amount. As ore with low levels of arsenic is depleted, these penalties will continue to rise.

from the earth’s geothermal resources into electrical energy. The fluids are recovered in the

from the earth’s geothermal resources into electrical energy. The fluids are recovered in the

boiler for a sulfite pulp mill in Quebec, Canada. The scrubber system is part of a larger green energy project that will produce 40-megawatts of power and increase annual production capacity of specialty cellulose by 5,000 metric tonnes. The new production capacity is slated to be complete by September 2014.

boiler for a sulfite pulp mill in Quebec, Canada. The scrubber system is part of a larger green energy project that will produce 40-megawatts of power and increase annual production capacity of specialty cellulose by 5,000 metric tonnes. The new production capacity is slated to be complete by September 2014. The sulfur containing effluent is re-used in the cellulose producton process. The sulfur recovery island is followed by a gas cleaning island comprised of an

The sulfur containing effluent is re-used in the cellulose producton process. The sulfur recovery island is followed by a gas cleaning island comprised of an