There are many applications that require packed bed absorbers for scrubbing SO2. Some applications  previously blogged about include refinery sulfur recovery unit tail gas treatment units (SRU/TGTU), geothermal power generation, and waste oil re-refining to name a few. Another SO2 scrubber example is gas cleaning equipment for a mineral processing application to recover gold and silver from mine sites with low grade ore. Discovered and patented in the early 1900 by Charles Merrill and later refined by Thomas Crowe, the Merrill-Crowe process is a common separation technique for removing gold and silver from a cyanide solution using zinc dust. Gold and silver precipitate (concentrate) is the product of the Merrill-Crowe process. Furnaces are then used to recover ingots from smelting Merrill-Crowe precipitate. Fluxes are mixed with the precipitate to bring impurities to the surface. The precious metals settles down and can then be easily removed.

previously blogged about include refinery sulfur recovery unit tail gas treatment units (SRU/TGTU), geothermal power generation, and waste oil re-refining to name a few. Another SO2 scrubber example is gas cleaning equipment for a mineral processing application to recover gold and silver from mine sites with low grade ore. Discovered and patented in the early 1900 by Charles Merrill and later refined by Thomas Crowe, the Merrill-Crowe process is a common separation technique for removing gold and silver from a cyanide solution using zinc dust. Gold and silver precipitate (concentrate) is the product of the Merrill-Crowe process. Furnaces are then used to recover ingots from smelting Merrill-Crowe precipitate. Fluxes are mixed with the precipitate to bring impurities to the surface. The precious metals settles down and can then be easily removed.

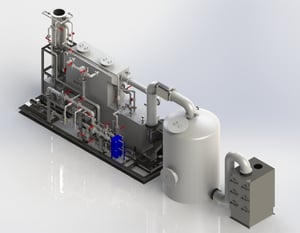

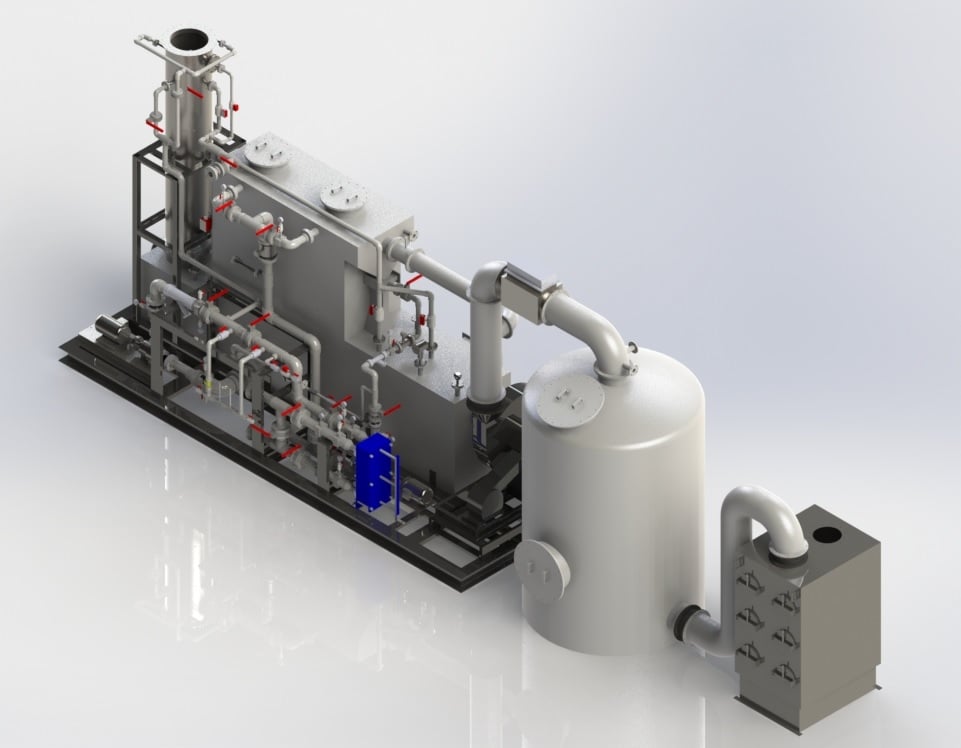

Envitech is currently building an SO2 scrubber to treat the exhaust gases from a melting furnace for a South American precious metals refinery mining project. Furnace off-gases are in the 300oF to 500oF range and contain particulate and SO2. A bag-house removes particulate from the gas before passing downstream to the packed bed absorber for SO2 removal. Gas is first cooled to saturation in an evaporative quencher using re-circulated water. In the case of a pump failure, an emergency spray nozzle provides an independent source of water controlled by a thermocouple. Water that has not evaporated flows from the quencher into the packed bed absorber sump. Gas from the quencher enters the bottom of the absorber and travels vertically upward through a packed bed. Recirculated water is sprayed over the packed bed and mixes with the counter current gas. A dilute solution of plant-supplied sodium hydroxide is metered into the scrubber recirculation line to neutralize acid gases and is controlled by pH of the absorber sump liquid. The scrubbing water is collected in the sump and is re-circulated to the top of the packed bed and to the quencher. A blowdown stream is taken from the recirculation line to purge the system of reaction products. After the packed bed, the gas passes through an entrainment separator to remove water droplets entrained in the gas during scrubbing. The gas then exits the scrubber and is exhausted to atmosphere through an ID fan and stack.

The scrubber scope of supply includes a quencher, packed bed absorber, instruments, control system, recirculation pump, piping, valves, and fittings, ID fan, and metering pump. The unit will be pre-assembled to the fullest extent possible with pre-mounted instruments pre-wired to a control panel. The assembly will be broken down as necessary for shipment and packaged for export to South America. Bilingual submittals are provided for the O&M manuals and engineering submittals. The scrubber will be delivered and started up in Q1 of 2019.

Click on the link below for a case study on the Merrill-Crowe Refining Furnace SO2 Scrubber and a packed bed absorber cut sheet.

Envitech developed a

Envitech developed a  Another example is a process vent scrubber for a blending facility in South Carolina that produces crop protection products for agricultural markets. The vent stream is 1,500 cfm and includes HCl and water soluble particulate greater than 3 micron in size. The Envitech lab scrubber was configured to include a low pressure drop Venturi for particulate control combined with a packed bed absorber for HCl control. The system includes instruments, control system, recirculation pump, pre-assembled piping, valves, and fittings, interconnect duct, ID fan, and stack.

Another example is a process vent scrubber for a blending facility in South Carolina that produces crop protection products for agricultural markets. The vent stream is 1,500 cfm and includes HCl and water soluble particulate greater than 3 micron in size. The Envitech lab scrubber was configured to include a low pressure drop Venturi for particulate control combined with a packed bed absorber for HCl control. The system includes instruments, control system, recirculation pump, pre-assembled piping, valves, and fittings, interconnect duct, ID fan, and stack.  A different use for a lab scrubber includes an ethylenediamine (

A different use for a lab scrubber includes an ethylenediamine (

Wet scrubbers are used to control hazardous air pollutants (HAPs) on many hospital, medical, and infectious waste incinerators (HMIWI). The Maximum Available Control Technology (MACT) standard for these incinerators was revised and became final in 2009. The new standard has the lowest emission limits for incinerators today. The limits exceeded the capability of systems designed to the previous standard with respect to particulate matter (PM), lead (Pd), cadmium (Cd), mercury (Hg), and dioxin/furans (D/F). By 2014 all existing medical waste incinerators were either shut down or upgraded to comply with the new standard. Envitech successfully upgraded four existing medical waste incinerators. A

Wet scrubbers are used to control hazardous air pollutants (HAPs) on many hospital, medical, and infectious waste incinerators (HMIWI). The Maximum Available Control Technology (MACT) standard for these incinerators was revised and became final in 2009. The new standard has the lowest emission limits for incinerators today. The limits exceeded the capability of systems designed to the previous standard with respect to particulate matter (PM), lead (Pd), cadmium (Cd), mercury (Hg), and dioxin/furans (D/F). By 2014 all existing medical waste incinerators were either shut down or upgraded to comply with the new standard. Envitech successfully upgraded four existing medical waste incinerators. A  rward will be new medical waste incinerators which have even more stringent, ultra-low emission limits. Building a new incinerator requires critical decisions on control technologies and permitting. The IT3/HWC paper reviews these issues for specific HAPs and discuss trade-offs between permitting a new medium size incinerator versus a large incinerator. An example is provided of an air pollution control system meeting the emission requirements for a new large medical waste incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. Envitech is also building gas cleaning systems for two new medium size medical waste incinerators for a research facility which integrate NOx control using ozone injection.

rward will be new medical waste incinerators which have even more stringent, ultra-low emission limits. Building a new incinerator requires critical decisions on control technologies and permitting. The IT3/HWC paper reviews these issues for specific HAPs and discuss trade-offs between permitting a new medium size incinerator versus a large incinerator. An example is provided of an air pollution control system meeting the emission requirements for a new large medical waste incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. Envitech is also building gas cleaning systems for two new medium size medical waste incinerators for a research facility which integrate NOx control using ozone injection.

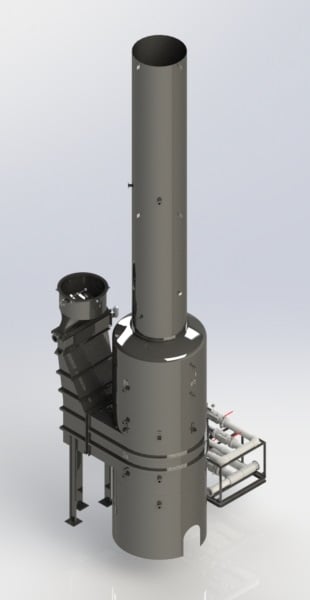

Banbury mixers are used, for instance, to compound rubber material for manufacturing automobile tires. Uncontrolled fumes from the mixers can create a nuisance by settling around the facility. Envitech’s Venturi collision scrubber has been used to control these fumes. The figure on the right shows a typical Venturi collision scrubber for a 25,000 cfm mixer exhaust. The scrubber separates the exhaust into two streams internal to the scrubber. The streams are then directed to two opposing Venturi throats. Recirculated water injected into each throat is atomized into fine droplets as the gas is accelerated. Fume particles and droplets collide and are captured by the atomized water as the steams are recombined into a third Venturi throat. A diffusion section redistributes the gas to a horizontal chevron style mist eliminator to remove entrained water droplets. Water is collected and drained into a common sump and recirculated back to the Venturi throats. A blowdown stream purges the collected material.

Banbury mixers are used, for instance, to compound rubber material for manufacturing automobile tires. Uncontrolled fumes from the mixers can create a nuisance by settling around the facility. Envitech’s Venturi collision scrubber has been used to control these fumes. The figure on the right shows a typical Venturi collision scrubber for a 25,000 cfm mixer exhaust. The scrubber separates the exhaust into two streams internal to the scrubber. The streams are then directed to two opposing Venturi throats. Recirculated water injected into each throat is atomized into fine droplets as the gas is accelerated. Fume particles and droplets collide and are captured by the atomized water as the steams are recombined into a third Venturi throat. A diffusion section redistributes the gas to a horizontal chevron style mist eliminator to remove entrained water droplets. Water is collected and drained into a common sump and recirculated back to the Venturi throats. A blowdown stream purges the collected material.

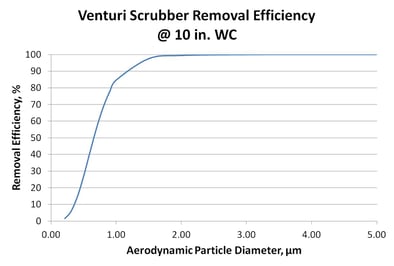

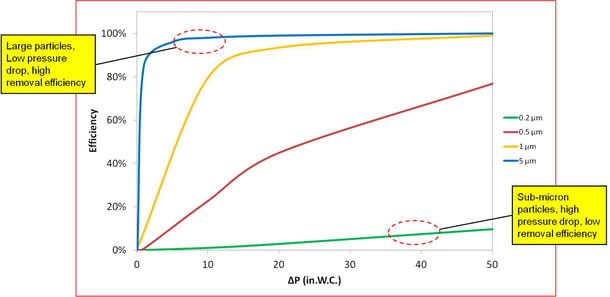

Venturi. It indicates that nearly all particles > 2 micron in size are removed by the Venturi. Performance drops off dramatically, however, for smaller particles. Mechanisms for particulate removal by a Venturi scrubber are discussed in more detail in an earlier

Venturi. It indicates that nearly all particles > 2 micron in size are removed by the Venturi. Performance drops off dramatically, however, for smaller particles. Mechanisms for particulate removal by a Venturi scrubber are discussed in more detail in an earlier  pressure drop over a minimum and maximum gas flow rate. The damper position is governed by proportional-integral-derivative control based on the differential pressure across the throat.

pressure drop over a minimum and maximum gas flow rate. The damper position is governed by proportional-integral-derivative control based on the differential pressure across the throat.

A common application for small scrubber systems is an emergency vent scrubber for l

A common application for small scrubber systems is an emergency vent scrubber for l

In 2009, the US EPA revised the emission limits for the Hospital, Medical, and Infectious Waste Incinerator (

In 2009, the US EPA revised the emission limits for the Hospital, Medical, and Infectious Waste Incinerator (

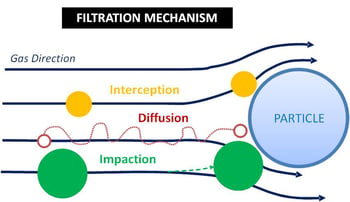

A Venturi scrubber is a common air pollution control device that is used to remove particulate. Because it is a wet scrubber, collected particulate is purged in a liquid discharge stream called the blowdown.

A Venturi scrubber is a common air pollution control device that is used to remove particulate. Because it is a wet scrubber, collected particulate is purged in a liquid discharge stream called the blowdown.

paper at the International Conference of Thermal Treatment

paper at the International Conference of Thermal Treatment  Technologies and Hazardous Waste Combustors (

Technologies and Hazardous Waste Combustors ( Pb reduction for a new large medical waste incinerator is even more dramatic. The emission limit is a mere 0.06% of the 1997 standard. Compared to an existing system permitted to the new standard, a large new medical waste incinerator must emit 2 orders of magnitude less Pb.

Pb reduction for a new large medical waste incinerator is even more dramatic. The emission limit is a mere 0.06% of the 1997 standard. Compared to an existing system permitted to the new standard, a large new medical waste incinerator must emit 2 orders of magnitude less Pb.