Early this year I posted about achieving ultra-low emission limits for medical waste incinerator scrubbers. An example was given for a captive incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. It’s one of the only systems in the United States permitted as a “new” medical waste incinerator according to the EPA HMIWI (hospital, medical, and infectious waste incinerator) MACT standard. This standard has the most challenging emission limits found in industry today. That is because in 2009 the EPA completed a source review and revised the standard based on a MACT-on-MACT analysis. Data used to set limits for each pollutant was individually based on waste feed and not incinerator/scrubber technology performance. This resulted in emission limit reductions for lead (Pb), cadmium (Cd), and dioxins/furans (D/F) that were orders of magnitude below the previous standard and below the capability of installed equipment. The impact of the new standard is discussed in greater detail in a 2013 blog post and corresponding paper from the Air & Waste Management Association (AWMA) International Conference on Thermal Treatment Technologies and Hazardous Waste Combustors (IT3/HWC)..

An example was given for a captive incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. It’s one of the only systems in the United States permitted as a “new” medical waste incinerator according to the EPA HMIWI (hospital, medical, and infectious waste incinerator) MACT standard. This standard has the most challenging emission limits found in industry today. That is because in 2009 the EPA completed a source review and revised the standard based on a MACT-on-MACT analysis. Data used to set limits for each pollutant was individually based on waste feed and not incinerator/scrubber technology performance. This resulted in emission limit reductions for lead (Pb), cadmium (Cd), and dioxins/furans (D/F) that were orders of magnitude below the previous standard and below the capability of installed equipment. The impact of the new standard is discussed in greater detail in a 2013 blog post and corresponding paper from the Air & Waste Management Association (AWMA) International Conference on Thermal Treatment Technologies and Hazardous Waste Combustors (IT3/HWC).. Existing incinerators needed to be upgraded with add-on controls to meet the new standard. New incinerators need air pollution control equipment capable of extraordinarily high removal efficiency for particulate, Pb, Cd, and D/F. A new medium sized incinerator between 200 to 500 lb/hr capacity, has the additional challenge of meeting NOx. A medical waste incinerator can be tuned to a NOx limit of about 130 ppmv. The MACT standard limit for a new medium sized medical waste incinerator was set at 67 ppmv which means NOx abatement is required to guarantee compliance.

Existing incinerators needed to be upgraded with add-on controls to meet the new standard. New incinerators need air pollution control equipment capable of extraordinarily high removal efficiency for particulate, Pb, Cd, and D/F. A new medium sized incinerator between 200 to 500 lb/hr capacity, has the additional challenge of meeting NOx. A medical waste incinerator can be tuned to a NOx limit of about 130 ppmv. The MACT standard limit for a new medium sized medical waste incinerator was set at 67 ppmv which means NOx abatement is required to guarantee compliance.

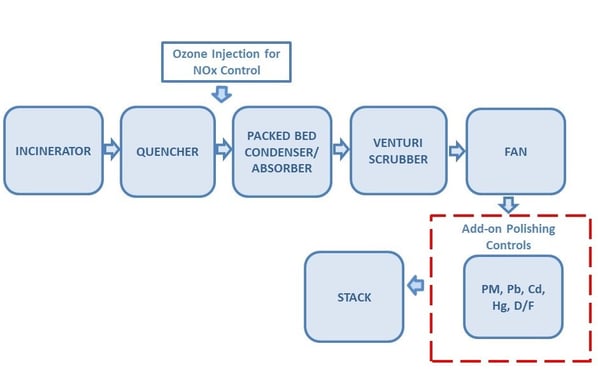

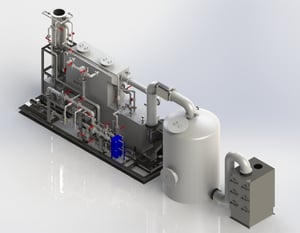

Envitech is building two scrubber systems to treat exhaust gases from two new medical waste incinerators that will treat captive waste at a research facility. The incinerators are permitted as new medium size incinerators which must meet the 67 ppmv NOx limit. The scrubbers have an equipment arrangement for meeting emission standards for PM, HCl, SO2, Pb, Cd, Hg, D/F, and opacity. The schematic below shows the components of the gas cleaning system. The quencher is used to cool the gas to saturation and remove large particulate. The packed bed condenser/absorber sub-cools the gas and removes acid gases with caustic injection. The Venturi scrubber removes particulate and the majority of heavy metals. The gas then passes through additional polishing controls to meet the ultra-low emission limits for Pd, Cd, Hg, and D/F. The polishing equipment includes a re-heat duct followed by a filter and carbon bed adsorber.

NOx removal is achieved by injecting ozone injection into the quencher outlet. The siz e of the condenser/absorber is increased to provide sufficient residence time for ozone-NOx reactions to occur. Ozone is highly selective for NOx relative to other combustion products. The NOx is rapidly converted to water soluble species. NO and O3 react to form NO2 and O2. NO2 and O2 react to form N2O5 and O2. N2O5 and water react to form 2HNO3 which is readily absorbed with caustic solution.

e of the condenser/absorber is increased to provide sufficient residence time for ozone-NOx reactions to occur. Ozone is highly selective for NOx relative to other combustion products. The NOx is rapidly converted to water soluble species. NO and O3 react to form NO2 and O2. NO2 and O2 react to form N2O5 and O2. N2O5 and water react to form 2HNO3 which is readily absorbed with caustic solution.

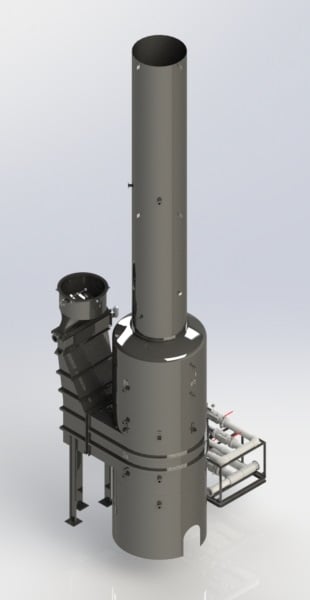

Envitech used it’s rectangular scrubber design for the condenser absorber. To maintain a modular design and make it shippable. The vessel was flanged connected and shipped in two pieces. The scrubber system otherwise looks like a typical medical waste incinerator scrubber except the condenser/absorber is double the height compared to systems that do not require NOx control.

The system has been built and shipped to the site. The major components are installed at the facility. Envitech will deliver a water treatment system in 2019 to treat the scrubber effluent before it is discharged to the facilities main water treatment system. System Start-up is scheduled for 2020.

Click on the link below to download a case study and other medical waste incinerator scrubbing literature.

previously blogged about include refinery sulfur recovery unit tail gas treatment units (

previously blogged about include refinery sulfur recovery unit tail gas treatment units (

Envitech developed a

Envitech developed a  Another example is a process vent scrubber for a blending facility in South Carolina that produces crop protection products for agricultural markets. The vent stream is 1,500 cfm and includes HCl and water soluble particulate greater than 3 micron in size. The Envitech lab scrubber was configured to include a low pressure drop Venturi for particulate control combined with a packed bed absorber for HCl control. The system includes instruments, control system, recirculation pump, pre-assembled piping, valves, and fittings, interconnect duct, ID fan, and stack.

Another example is a process vent scrubber for a blending facility in South Carolina that produces crop protection products for agricultural markets. The vent stream is 1,500 cfm and includes HCl and water soluble particulate greater than 3 micron in size. The Envitech lab scrubber was configured to include a low pressure drop Venturi for particulate control combined with a packed bed absorber for HCl control. The system includes instruments, control system, recirculation pump, pre-assembled piping, valves, and fittings, interconnect duct, ID fan, and stack.  A different use for a lab scrubber includes an ethylenediamine (

A different use for a lab scrubber includes an ethylenediamine (

Wet scrubbers are used to control hazardous air pollutants (HAPs) on many hospital, medical, and infectious waste incinerators (HMIWI). The Maximum Available Control Technology (MACT) standard for these incinerators was revised and became final in 2009. The new standard has the lowest emission limits for incinerators today. The limits exceeded the capability of systems designed to the previous standard with respect to particulate matter (PM), lead (Pd), cadmium (Cd), mercury (Hg), and dioxin/furans (D/F). By 2014 all existing medical waste incinerators were either shut down or upgraded to comply with the new standard. Envitech successfully upgraded four existing medical waste incinerators. A

Wet scrubbers are used to control hazardous air pollutants (HAPs) on many hospital, medical, and infectious waste incinerators (HMIWI). The Maximum Available Control Technology (MACT) standard for these incinerators was revised and became final in 2009. The new standard has the lowest emission limits for incinerators today. The limits exceeded the capability of systems designed to the previous standard with respect to particulate matter (PM), lead (Pd), cadmium (Cd), mercury (Hg), and dioxin/furans (D/F). By 2014 all existing medical waste incinerators were either shut down or upgraded to comply with the new standard. Envitech successfully upgraded four existing medical waste incinerators. A  rward will be new medical waste incinerators which have even more stringent, ultra-low emission limits. Building a new incinerator requires critical decisions on control technologies and permitting. The IT3/HWC paper reviews these issues for specific HAPs and discuss trade-offs between permitting a new medium size incinerator versus a large incinerator. An example is provided of an air pollution control system meeting the emission requirements for a new large medical waste incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. Envitech is also building gas cleaning systems for two new medium size medical waste incinerators for a research facility which integrate NOx control using ozone injection.

rward will be new medical waste incinerators which have even more stringent, ultra-low emission limits. Building a new incinerator requires critical decisions on control technologies and permitting. The IT3/HWC paper reviews these issues for specific HAPs and discuss trade-offs between permitting a new medium size incinerator versus a large incinerator. An example is provided of an air pollution control system meeting the emission requirements for a new large medical waste incinerator at the University of Texas Medical Branch (UTMB) in Galveston, TX. Envitech is also building gas cleaning systems for two new medium size medical waste incinerators for a research facility which integrate NOx control using ozone injection.

Ethylene amines are one of the major chemical building blocks. Ethylene amines include ethylenediamine (EDA), diethylenetriamine (DETA), triethyltriamine (TETA) as well as other longer chained ethylene amines. Amongst its many uses, ethylene amine is one of the two principal chemical ingredients in making ethylenediaminetetracetic acid (EDTA), the most common chelating agent in the world. Diamines are also used in the manufacture of the ubiquitious textile Nylon. Due to its excellent properties, it is also used extensively in the asphalt, petrochemical, rubber, pesticide, and paper industries.

Ethylene amines are one of the major chemical building blocks. Ethylene amines include ethylenediamine (EDA), diethylenetriamine (DETA), triethyltriamine (TETA) as well as other longer chained ethylene amines. Amongst its many uses, ethylene amine is one of the two principal chemical ingredients in making ethylenediaminetetracetic acid (EDTA), the most common chelating agent in the world. Diamines are also used in the manufacture of the ubiquitious textile Nylon. Due to its excellent properties, it is also used extensively in the asphalt, petrochemical, rubber, pesticide, and paper industries.

Banbury mixers are used, for instance, to compound rubber material for manufacturing automobile tires. Uncontrolled fumes from the mixers can create a nuisance by settling around the facility. Envitech’s Venturi collision scrubber has been used to control these fumes. The figure on the right shows a typical Venturi collision scrubber for a 25,000 cfm mixer exhaust. The scrubber separates the exhaust into two streams internal to the scrubber. The streams are then directed to two opposing Venturi throats. Recirculated water injected into each throat is atomized into fine droplets as the gas is accelerated. Fume particles and droplets collide and are captured by the atomized water as the steams are recombined into a third Venturi throat. A diffusion section redistributes the gas to a horizontal chevron style mist eliminator to remove entrained water droplets. Water is collected and drained into a common sump and recirculated back to the Venturi throats. A blowdown stream purges the collected material.

Banbury mixers are used, for instance, to compound rubber material for manufacturing automobile tires. Uncontrolled fumes from the mixers can create a nuisance by settling around the facility. Envitech’s Venturi collision scrubber has been used to control these fumes. The figure on the right shows a typical Venturi collision scrubber for a 25,000 cfm mixer exhaust. The scrubber separates the exhaust into two streams internal to the scrubber. The streams are then directed to two opposing Venturi throats. Recirculated water injected into each throat is atomized into fine droplets as the gas is accelerated. Fume particles and droplets collide and are captured by the atomized water as the steams are recombined into a third Venturi throat. A diffusion section redistributes the gas to a horizontal chevron style mist eliminator to remove entrained water droplets. Water is collected and drained into a common sump and recirculated back to the Venturi throats. A blowdown stream purges the collected material.

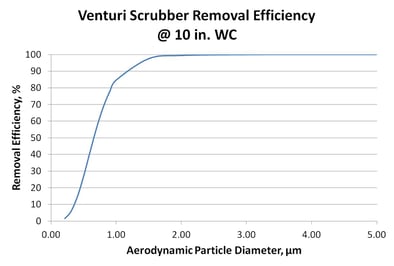

Venturi. It indicates that nearly all particles > 2 micron in size are removed by the Venturi. Performance drops off dramatically, however, for smaller particles. Mechanisms for particulate removal by a Venturi scrubber are discussed in more detail in an earlier

Venturi. It indicates that nearly all particles > 2 micron in size are removed by the Venturi. Performance drops off dramatically, however, for smaller particles. Mechanisms for particulate removal by a Venturi scrubber are discussed in more detail in an earlier  pressure drop over a minimum and maximum gas flow rate. The damper position is governed by proportional-integral-derivative control based on the differential pressure across the throat.

pressure drop over a minimum and maximum gas flow rate. The damper position is governed by proportional-integral-derivative control based on the differential pressure across the throat.

A common application for small scrubber systems is an emergency vent scrubber for l

A common application for small scrubber systems is an emergency vent scrubber for l